The process encompasses the removal of accumulated debris, such as soot, creosote, and other obstructions, from both the vertical exhaust conduit attached to a building’s heating appliance and the appliance itself. This service ensures the safe and efficient operation of heating systems, preventing potential hazards like chimney fires and carbon monoxide poisoning. Examples include sweeping away creosote buildup in a brick structure’s flue or vacuuming soot from the heat exchanger of a central heating unit.

Regular maintenance offers significant advantages, including improved heating efficiency, reduced energy consumption, and extended lifespan of both the chimney and the heating appliance. Historically, this practice was crucial for maintaining warmth and safety in homes relying on wood or coal for heat. Neglecting this maintenance can lead to decreased heating effectiveness, increased fuel costs, and potentially dangerous conditions within the dwelling.

The following sections will detail the methods employed, the tools utilized, the frequency recommended, and the factors influencing the cost of these essential services. It will also address the importance of professional inspections and certifications in ensuring proper system maintenance and safety adherence.

Essential Maintenance Guidance

The following guidance provides actionable steps to ensure the longevity and safety of heating systems. Consistent adherence to these recommendations promotes efficient operation and reduces the risk of potential hazards.

Tip 1: Schedule Annual Professional Inspections. A certified technician can identify hidden damage or deterioration that may not be readily apparent. This proactive approach mitigates potential safety risks and ensures optimal performance.

Tip 2: Remove Obstructions Regularly. Clear away any foliage, bird nests, or other debris that could block the flue. Obstructions impede proper ventilation and can lead to dangerous buildup of gases.

Tip 3: Utilize Appropriate Fuel Types. Employ only fuels that are specifically approved for the heating appliance. Using unsuitable fuels can damage the system and create hazardous emissions.

Tip 4: Monitor for Signs of Inefficiency. Observe the heating system’s performance. Indications such as unusual noises, excessive smoke, or a noticeable increase in fuel consumption warrant immediate professional attention.

Tip 5: Ensure Proper Ventilation. Verify that the area surrounding the heating appliance is adequately ventilated. Sufficient airflow is crucial for combustion and prevents the accumulation of carbon monoxide.

Tip 6: Keep Surroundings Clear. Maintain a safe distance between the heating system and any flammable materials. This precaution reduces the risk of accidental fires.

Tip 7: Document Maintenance Records. Keep detailed records of all inspections, services, and repairs performed. Accurate documentation provides a valuable reference for future maintenance and potential warranty claims.

By implementing these practices, homeowners can significantly enhance the safety, efficiency, and lifespan of their heating systems, contributing to a safer and more comfortable living environment.

The subsequent sections will explore the financial considerations associated with professional services and the long-term benefits of proactive system care.

1. Soot Removal

Soot removal is a critical component of comprehensive heating system maintenance. Soot, a byproduct of incomplete combustion, accumulates within chimneys and furnaces during regular operation. The presence of soot reduces the efficiency of heat transfer, leading to increased fuel consumption and diminished heating capacity. Furthermore, excessive soot buildup can obstruct flue passages, impeding the proper ventilation of combustion gases, including carbon monoxide. Incomplete combustion is usually the primary cause. For example, insufficient oxygen supply for the burning fuel or an improperly adjusted burner can lead to soot formation, resulting in lower heat output and higher fuel costs.

The process of soot removal typically involves the use of specialized brushes, vacuums, and other tools designed to dislodge and extract the accumulated deposits from the internal surfaces of the chimney and furnace. Neglecting this process can result in a range of problems, including reduced heating system efficiency, increased risk of chimney fires due to the ignitability of soot deposits, and elevated levels of carbon monoxide within the dwelling. A practical application of this understanding is the implementation of scheduled cleaning regimes, which involves engaging qualified professionals to conduct periodic soot removal services. Such services ensure the safe and efficient operation of the heating system and mitigates the potential hazards associated with soot accumulation.

In summary, soot removal is a vital aspect of ensuring the safe and efficient operation of heating systems. Addressing soot accumulation through regular cleaning promotes optimal combustion, reduces the risk of fire and carbon monoxide exposure, and extends the lifespan of the heating appliance. Challenges associated with soot removal include accessing difficult-to-reach areas within chimneys and furnaces. Understanding the significance of soot removal reinforces the broader theme of proactive maintenance and its contribution to occupant safety and energy conservation.

2. Creosote Mitigation

Creosote mitigation is a fundamental objective within the broader scope of chimney and furnace maintenance. It addresses the accumulation of a highly flammable byproduct resulting from incomplete combustion of solid fuels. Effective strategies reduce fire risks and ensure safe, efficient heating system operation.

- Creosote Formation Processes

Creosote forms when unburned gases and particles from wood or coal combustion condense within the cooler sections of a chimney. Factors like low flue temperatures, insufficient air supply, and burning unseasoned wood exacerbate this process. Mitigation involves optimizing combustion to minimize unburned byproducts and regulating flue temperatures to prevent condensation.

- Creosote Types and Hazards

Creosote exists in varying forms, ranging from a flaky, easily removable deposit to a hard, tar-like glaze. The glazed form is particularly hazardous due to its resistance to conventional removal methods and its high flammability. Understanding creosote types enables tailored cleaning approaches to address specific buildup characteristics.

- Mitigation Techniques and Tools

Effective mitigation employs a combination of mechanical and chemical methods. Mechanical removal involves using specialized brushes and scraping tools to dislodge creosote deposits. Chemical treatments can modify the creosote, making it easier to remove or rendering it less flammable. The selection of appropriate techniques depends on creosote type and chimney construction.

- Preventative Measures

Preventive practices minimize creosote accumulation. These include burning seasoned wood, ensuring adequate air supply to the fire, and maintaining appropriate flue temperatures. Regular chimney inspections and cleaning schedules, tailored to fuel type and usage patterns, are essential components of creosote mitigation strategies.

The facets of creosote mitigation, when addressed comprehensively, contribute to the safe and efficient functioning of heating systems. Proactive creosote management minimizes fire hazards, optimizes heating efficiency, and extends the lifespan of chimneys and furnaces. Integrating these strategies into routine maintenance practices is crucial for safeguarding property and occupants from the risks associated with creosote accumulation.

3. Ventilation Optimization

Ventilation optimization constitutes a critical, yet sometimes overlooked, aspect of maintaining safe and efficient heating systems. Effective ventilation ensures the proper removal of combustion byproducts, prevents the buildup of dangerous gases, and contributes to overall system performance. Integrating ventilation optimization into routine cleaning practices is essential for mitigating risks and maximizing system benefits.

- Airflow Dynamics

Airflow dynamics within the chimney and furnace system directly impact combustion efficiency and byproduct removal. Adequate airflow facilitates complete combustion, reducing soot and creosote formation. Insufficient airflow hinders combustion, leading to increased pollutant production and potential carbon monoxide buildup. Regular inspections and adjustments to ventilation components, such as dampers and air inlets, are crucial for maintaining optimal airflow patterns.

- Draft Regulation

Draft, the pressure differential that draws combustion gases up the chimney, must be properly regulated to ensure effective ventilation. Excessive draft can lead to rapid heat loss and increased fuel consumption, while insufficient draft can cause backdrafting of combustion gases into the living space. Devices such as barometric dampers are employed to maintain consistent draft levels, regardless of external weather conditions or flue temperature fluctuations.

- Flue Obstructions

Flue obstructions, such as bird nests, debris, or deteriorated chimney liners, impede ventilation and increase the risk of carbon monoxide poisoning. Regular chimney sweeping removes these obstructions, restoring proper airflow and ensuring the safe venting of combustion gases. Addressing flue obstructions is a fundamental step in optimizing ventilation and preventing potential hazards.

- Combustion Air Supply

Adequate combustion air supply is essential for complete and efficient fuel burning. Insufficient combustion air can lead to incomplete combustion, resulting in increased pollutant emissions and reduced heating efficiency. Ensuring that the heating appliance receives an adequate supply of fresh air is crucial for maintaining optimal combustion and ventilation performance. This may involve providing dedicated air inlets or ensuring adequate ventilation within the appliance room.

These interlinked facets of ventilation optimization highlight its importance in maximizing the safety and efficiency of chimney and furnace systems. Regular cleaning and inspection, coupled with appropriate adjustments to ventilation components, ensure the effective removal of combustion byproducts, minimize the risk of carbon monoxide poisoning, and promote the long-term performance of heating appliances. Prioritizing ventilation optimization as part of routine maintenance is an investment in safety, efficiency, and the longevity of the heating system.

4. Combustion Efficiency

The effectiveness with which a heating system converts fuel into usable heat is directly influenced by the cleanliness of its chimney and furnace components. A buildup of soot, creosote, and other debris impedes efficient combustion. This accumulation restricts airflow, disrupts the proper mixing of fuel and oxygen, and reduces the system’s ability to transfer heat effectively. Consequently, a system burdened by such deposits requires more fuel to generate the same amount of heat, leading to increased energy consumption and higher operating costs. Regular maintenance, specifically involving the removal of these deposits, restores the system’s ability to achieve optimal combustion efficiency.

Consider a residential furnace operating with a significantly soiled heat exchanger. The layer of soot insulates the exchanger, preventing it from effectively transferring heat to the circulating air. This necessitates a prolonged burner operation to meet the thermostat setting, resulting in wasted fuel and increased carbon emissions. Following a professional cleaning, the heat exchanger’s efficiency is restored, allowing for faster and more complete heat transfer. Another example involves a wood-burning stove with a creosote-lined chimney. The creosote restricts airflow, causing incomplete combustion and producing higher levels of smoke and pollutants. Cleaning the chimney removes the creosote, improving airflow and promoting a cleaner, more efficient burn.

In summary, maintaining clean chimney and furnace systems is not merely about preventing hazards; it is fundamentally linked to maximizing combustion efficiency. The accumulation of combustion byproducts negatively impacts the system’s ability to convert fuel into heat, leading to increased energy consumption and environmental impact. Regular professional cleaning and inspection are essential for restoring and maintaining optimal combustion efficiency, resulting in reduced fuel costs, lower emissions, and extended equipment lifespan. The challenges associated with neglecting this essential maintenance underscore the practical significance of understanding the direct correlation between cleanliness and efficiency in heating systems.

5. Carbon Monoxide Prevention

Carbon monoxide (CO) prevention is inextricably linked to routine chimney and furnace cleaning, acting as a primary safety outcome of effective maintenance. CO, an odorless and colorless gas, is a byproduct of incomplete combustion in fuel-burning appliances such as furnaces, stoves, and water heaters. The accumulation of soot, creosote, and other obstructions within chimneys and furnaces hinders proper ventilation, leading to incomplete combustion and a consequential increase in CO production. If these gases cannot escape effectively through the flue system due to blockages, they can backdraft into the living space, posing a severe health risk to occupants. Therefore, the removal of these obstructions through regular cleaning directly mitigates the risk of CO poisoning.

The presence of even small amounts of CO can lead to symptoms such as headaches, dizziness, and nausea, while higher concentrations can cause loss of consciousness and death. For instance, a furnace with a severely blocked flue may produce dangerously high levels of CO, which could leak into a home, especially during periods of heavy use in colder months. The routine service, including thorough inspection and cleaning, ensures unobstructed ventilation and proper combustion, diminishing the potential for CO to accumulate to hazardous levels. Proper cleaning also allows for the identification of potential cracks or deterioration in the chimney or furnace that could allow CO to leak into the home, further enhancing preventative measures.

In conclusion, carbon monoxide prevention forms a cornerstone of chimney and furnace cleaning practices. The direct relationship between system cleanliness, proper ventilation, and reduced CO production underscores the critical importance of regular maintenance. While CO detectors provide an essential safety net, they should not be considered a substitute for proactive system care. Addressing the potential for CO buildup through routine cleaning presents a crucial measure for safeguarding occupants and ensuring a healthy indoor environment. Challenges associated with recognizing the subtle signs of CO exposure highlight the practical significance of diligent preventative maintenance.

6. System Longevity

The operational lifespan of heating systems, referred to as system longevity, is significantly influenced by regular maintenance practices. The accumulation of combustion byproducts and general wear and tear can degrade system components over time, diminishing performance and accelerating the need for replacement. Scheduled services focused on removing these deposits directly correlate with extending the functional lifespan of chimneys and furnaces.

- Corrosion Mitigation

Combustion byproducts, particularly acidic compounds, can corrode metal components within the chimney and furnace. Regular cleaning removes these corrosive agents, preventing premature deterioration and extending the life of critical parts such as heat exchangers and flue liners. Neglecting this leads to costly repairs or full system replacement.

- Stress Reduction on Components

Accumulated soot and debris impede proper airflow and heat transfer, causing components to work harder and operate at higher temperatures. This increased stress accelerates wear and tear, shortening the lifespan of the system. Routine maintenance alleviates this stress by restoring optimal operating conditions, preventing premature failure of components such as blowers, motors, and controls.

- Fuel Efficiency Preservation

As systems age and accumulate deposits, fuel efficiency declines, placing additional strain on system components. A furnace struggling to heat a space due to reduced efficiency operates for longer periods, leading to increased wear on its burner, blower, and other parts. Maintaining a clean system ensures fuel efficiency is sustained, minimizing stress and prolonging component life.

- Prevention of Catastrophic Failure

Neglecting maintenance can lead to catastrophic system failures, such as chimney fires or cracked heat exchangers. These failures not only pose significant safety risks but also often necessitate complete system replacement. Regular cleaning and inspection identify and address potential issues before they escalate into major problems, preventing costly and disruptive failures and preserving the system’s overall lifespan.

The facets detailed above collectively demonstrate that chimney and furnace cleaning directly promotes system longevity. Proactive maintenance addresses corrosion, reduces stress on components, preserves fuel efficiency, and prevents catastrophic failures, all of which contribute to extending the operational lifespan of heating systems. The cost of regular maintenance is demonstrably less than the expense of premature system replacement, making it a prudent investment in long-term cost savings and system reliability.

7. Professional Inspection

A professional inspection provides a comprehensive assessment of chimney and furnace systems, surpassing the scope of routine cleaning. It is a critical element in ensuring safe and efficient operation, often revealing hidden issues undetectable through standard maintenance procedures. The inspection process identifies potential hazards and performance inefficiencies, guiding targeted cleaning efforts.

- Structural Integrity Assessment

A qualified inspector evaluates the structural condition of the chimney, examining the masonry for cracks, spalling, or deterioration. Internal flue liners are inspected for damage, ensuring proper venting of combustion gases. The stability of the chimney structure is verified, addressing any potential safety concerns related to collapse or instability. Structural deficiencies discovered during inspection inform necessary repairs or modifications, safeguarding the chimney’s function and preventing hazardous conditions. Example: Identifying a cracked flue liner allows for prompt repair to prevent carbon monoxide leakage.

- Appliance Performance Evaluation

The performance of the furnace or heating appliance is assessed, evaluating combustion efficiency and identifying any operational issues. Burner functionality, heat exchanger integrity, and control system operation are analyzed. The inspector checks for proper fuel-air mixture, ensuring optimal combustion and minimizing pollutant emissions. Performance deficiencies identified during evaluation guide necessary adjustments or repairs, optimizing system efficiency and reducing energy consumption. Example: Measuring flue gas composition reveals improper combustion, prompting burner adjustment for improved efficiency.

- Safety System Verification

Safety systems related to chimney and furnace operation are verified, ensuring they are functioning correctly. Carbon monoxide detectors are tested, and their placement is evaluated for optimal coverage. Gas leak detection is performed to identify any potential hazards. Safety controls, such as high-limit switches and flame sensors, are checked for proper operation. Safety system deficiencies identified during verification are addressed promptly, enhancing occupant safety and preventing potential hazards. Example: Confirming the proper function of a high-limit switch prevents furnace overheating.

- Code Compliance Review

The installation and operation of the chimney and furnace system are reviewed for compliance with relevant building codes and safety regulations. Clearance requirements for combustible materials are verified, minimizing fire hazards. Proper venting configurations are assessed, ensuring adequate exhaust of combustion gases. Code violations identified during review are addressed to bring the system into compliance, mitigating potential safety risks and ensuring legal operation. Example: Verifying proper chimney height above the roofline to meet code requirements and ensure adequate draft.

These interconnected facets of professional inspection reinforce its value as a complement to routine chimney and furnace cleaning. The inspection process provides a comprehensive assessment, identifying underlying issues and guiding targeted maintenance efforts. Addressing deficiencies revealed through professional inspection maximizes system safety, efficiency, and longevity, offering a holistic approach to maintaining reliable and secure heating systems.

Frequently Asked Questions

The following addresses common inquiries regarding this maintenance practice. Understanding the nuances contributes to informed decisions and improved system care.

Question 1: What constitutes the primary objective?

The primary objective involves removing accumulated debris, soot, and creosote from the chimney flue and the furnace itself. This ensures safe operation and mitigates potential hazards.

Question 2: How frequently should this service be performed?

Annual professional inspection and service is generally recommended. Systems subjected to heavy use may require more frequent attention.

Question 3: What are the potential consequences of neglecting this maintenance?

Neglecting this maintenance increases the risk of chimney fires, carbon monoxide poisoning, reduced heating efficiency, and accelerated system deterioration.

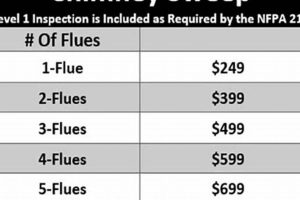

Question 4: What factors influence the cost of professional service?

Cost is influenced by factors such as chimney height, system complexity, extent of debris accumulation, and geographic location.

Question 5: Does sweeping guarantee elimination of all hazards?

While sweeping reduces risks, professional inspection identifies potential structural issues or hidden damage not readily apparent during a cleaning. The inspection enhances total safety.

Question 6: Can homeowners perform this cleaning independently?

While some basic tasks like debris removal can be done, professional service involves specialized tools and expertise for thorough cleaning and safety inspections, best left to trained technicians.

Prioritizing safety is very important. Consult qualified professionals for assessment, maintenance, and solutions for a well function. Keep in mind a routine check can keep you away from the unexpected and maintain stability.

Please read the conclusion for more insights and a recap.

Conclusion

This exploration has underscored the indispensable role of chimney and furnace cleaning in maintaining the safety, efficiency, and longevity of residential heating systems. The accumulation of soot, creosote, and other combustion byproducts presents tangible risks, including chimney fires, carbon monoxide poisoning, and diminished heating performance. Routine chimney and furnace cleaning, coupled with professional inspection, mitigates these threats, ensuring the secure and cost-effective operation of vital household infrastructure.

The long-term benefits of proactive maintenance outweigh the immediate costs, safeguarding property, protecting occupants, and optimizing energy consumption. Neglecting chimney and furnace cleaning leads to inevitable system degradation and heightened risk of catastrophic failure. Homeowners are strongly encouraged to prioritize scheduled service, fostering a safer living environment and ensuring the enduring performance of their heating systems. The continued adoption of professional chimney and furnace cleaning practices remains paramount for responsible homeownership.

![Buy Best Chimney Cleaning Brush at Home Depot [Guide] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Buy Best Chimney Cleaning Brush at Home Depot [Guide] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/01/th-723-300x200.jpg)