Water intrusion affecting a vertical venting structure, often constructed of brick, stone, or metal, and designed to exhaust combustion byproducts from a fireplace, furnace, or other heating appliance, poses a significant threat to a building’s structural integrity. For example, rainwater penetrating deteriorated mortar joints on a brick chimney can saturate the surrounding masonry and eventually infiltrate the interior of the dwelling.

Addressing such vulnerabilities is crucial because unmitigated water damage can lead to costly repairs involving compromised building materials and potential health hazards associated with mold growth. Historically, regular maintenance and preventative measures have been essential components in safeguarding these structures from the deteriorating effects of weathering and age. Early detection allows for less invasive and more cost-effective remediation strategies.

The subsequent sections will detail common causes of this phenomenon, diagnostic techniques for identifying the source of the problem, and established repair methods for ensuring long-term protection of both the structure and the surrounding environment.

Addressing Moisture Intrusion in Vertical Vents

Proactive measures and diligent maintenance are essential in preventing structural damage and potential hazards associated with water penetration in these structures. The following recommendations offer guidance on minimizing the risk and mitigating the impact of such issues.

Tip 1: Conduct Regular Inspections: Examine the structure at least annually, preferably in the spring and fall. Pay close attention to the condition of the crown, flashing, and mortar joints. Look for signs of cracking, spalling, or deterioration.

Tip 2: Maintain a Sound Crown: Ensure the crown is properly constructed and in good repair. This protective cap prevents water from directly entering the flue. A damaged or deteriorated crown should be promptly repaired or replaced.

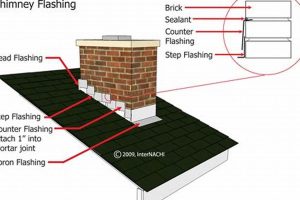

Tip 3: Inspect and Seal Flashing: The flashing, where the chimney meets the roof, is a critical area. Check for gaps, corrosion, or damage. Re-seal or replace flashing as needed to create a watertight barrier.

Tip 4: Address Mortar Joint Deterioration: Crumbling or cracked mortar joints allow water to penetrate the masonry. Repointing, the process of removing and replacing deteriorated mortar, is essential for maintaining structural integrity.

Tip 5: Ensure Proper Drainage: Verify that the drainage system around the base of the structure is functioning correctly. Standing water can contribute to moisture problems and accelerate deterioration.

Tip 6: Install a Chimney Cap: A properly fitted cap prevents rainwater, snow, and debris from entering the flue, reducing the risk of water damage and blockages.

Tip 7: Monitor for Interior Signs: Be vigilant for signs of water damage on interior walls and ceilings near the structure. Water stains, discoloration, or peeling paint may indicate an ongoing issue.

Implementing these preventative measures helps safeguard the structural integrity of the chimney, minimizes the risk of costly repairs, and ensures the safe and efficient operation of heating appliances. Addressing potential issues promptly prevents escalation and protects the overall building envelope.

The subsequent sections will elaborate on specific repair techniques and material choices for effectively addressing these issues and ensuring long-term protection against water damage.

1. Mortar Joint Degradation

Deteriorated mortar joints represent a primary entry point for water into brick or stone structures. The cementitious material binding individual masonry units gradually weakens due to weathering, freeze-thaw cycles, and chemical erosion. This weakening creates pathways through which rainwater, snowmelt, and atmospheric moisture can penetrate, leading to internal saturation. This permeation, in turn, accelerates the deterioration process, establishing a self-perpetuating cycle of damage. A visual inspection often reveals crumbling, cracking, or missing mortar, indicating a compromised barrier against water intrusion.

The consequences of unchecked mortar degradation extend beyond cosmetic concerns. Water entering the masonry can freeze and expand, exerting pressure on the surrounding bricks or stones and causing spalling or cracking. This structural damage compromises the integrity of the chimney, potentially leading to instability or collapse. Furthermore, the moisture promotes the growth of mold and mildew within the structure and adjacent building materials, posing health risks and necessitating costly remediation. For example, a homeowner neglecting regular maintenance may observe water stains on interior walls near the base of the chimney, signaling advanced mortar deterioration and internal water damage.

Therefore, timely identification and repair of mortar joint degradation are crucial for preventing water intrusion and preserving the structural integrity of masonry chimneys. Repointing, the process of removing and replacing deteriorated mortar, effectively restores the protective barrier, preventing water penetration and mitigating further damage. Regular inspections and proactive maintenance are essential components of a comprehensive strategy for safeguarding these structures against the detrimental effects of water.

2. Flashing inadequacy

Flashing, a critical component in preventing water intrusion, forms a weatherproof seal where the chimney structure intersects the roof. Inadequate or improperly installed flashing represents a significant vulnerability, directly contributing to chimney leaks and associated structural damage. The effectiveness of flashing relies on proper materials, design, and installation, all of which are susceptible to degradation and failure over time.

- Material Degradation and Corrosion

Flashing materials, typically aluminum, copper, or galvanized steel, are subject to corrosion and deterioration due to environmental exposure. Over time, exposure to moisture, temperature fluctuations, and chemical pollutants can weaken the flashing, leading to cracks, holes, or separation from the chimney or roof. This degradation compromises the water-tight seal, allowing water to penetrate the structure. For instance, galvanized steel flashing may rust in coastal environments, while aluminum can corrode when in contact with certain dissimilar metals. The resulting leaks can lead to significant water damage within the building.

- Improper Installation Techniques

Incorrect installation is a common cause of flashing failure. If flashing is not properly integrated with the roofing material and the chimney masonry, gaps or openings can occur, providing pathways for water entry. For example, flashing that is not adequately lapped or sealed can allow water to flow behind the flashing and into the building. Similarly, flashing that is not properly secured to the chimney can become dislodged by wind or ice, creating a direct route for water to enter. Proper installation requires adherence to established building codes and best practices.

- Design Flaws and Incompatible Materials

Design deficiencies in the flashing system can also contribute to water intrusion. Flashing designs that do not adequately account for water runoff or expansion and contraction due to temperature changes are prone to failure. Additionally, using incompatible materials in the flashing system can lead to corrosion and degradation. For example, using aluminum flashing in direct contact with pressure-treated lumber can cause rapid corrosion of the aluminum due to chemical reactions. Appropriate material selection and design considerations are crucial for ensuring long-term performance.

- Lack of Maintenance and Inspection

Neglecting regular inspection and maintenance allows minor flashing issues to escalate into significant problems. Cracks, loose seams, or corrosion may go unnoticed until substantial water damage occurs. Regular inspection, ideally performed annually, can identify potential problems early, allowing for timely repairs and preventing costly damage. Simple maintenance tasks, such as sealing gaps or replacing damaged sections of flashing, can significantly extend the lifespan of the flashing system and prevent water intrusion.

In conclusion, addressing flashing inadequacy requires a comprehensive approach that includes proper material selection, meticulous installation techniques, sound design principles, and diligent maintenance practices. Failure to address these factors can result in persistent chimney leaks, leading to structural damage, mold growth, and other related issues. Therefore, prioritizing the integrity of the flashing system is essential for protecting buildings from water damage and ensuring the long-term performance of the chimney.

3. Crown Compromise

The chimney crown, a concrete or masonry slab covering the top of the chimney structure, serves as the primary defense against water intrusion. A compromised crown, characterized by cracks, deterioration, or improper construction, directly facilitates the ingress of water into the chimney system, resulting in leakage. This component deflects rainwater and snow away from the flue, preventing direct exposure and subsequent damage. Failure of the crown due to age, weathering, or substandard materials renders the chimney vulnerable to significant water damage.

When the crown develops cracks, water penetrates the underlying masonry, leading to freeze-thaw damage and accelerated deterioration of the chimney structure. This water infiltration can extend to interior walls and ceilings, causing staining, peeling paint, and potential mold growth. For instance, a homeowner might observe water stains on the ceiling below the chimney following periods of heavy rain, indicating a compromised crown. The resulting moisture can also damage the flue liner, reducing its efficiency and potentially creating a fire hazard. A deteriorated crown necessitates timely repair or replacement to prevent further structural damage and associated expenses. The lack of maintenance on this vital component can lead to costlier repairs, affecting the integrity and safety of the chimney system.

In summary, the integrity of the chimney crown is paramount in preventing water infiltration and ensuring the longevity of the chimney. Regular inspections and proactive maintenance, including sealing cracks and applying a waterproof coating, are essential for preserving the crown’s protective function. Neglecting crown maintenance exposes the chimney to significant water damage, impacting structural integrity and potentially compromising building safety. Addressing crown compromise promptly is crucial for maintaining a dry, safe, and efficient chimney system.

4. Flue Obstruction

Flue obstruction directly correlates with chimney leaks, creating conditions that exacerbate water intrusion and related damage. A clear and unobstructed flue is essential for the proper venting of combustion gases and moisture. When blockages occur, the chimney system’s capacity to expel moisture is compromised, leading to potential leaks and structural deterioration.

- Condensation Buildup

Obstructions impede the upward flow of warm, moist gases, causing them to cool and condense within the chimney. This condensation, containing corrosive byproducts of combustion, saturates the flue liner and masonry, accelerating deterioration. For instance, creosote buildup from wood-burning stoves restricts airflow, increasing condensation and subsequent water damage. The resulting saturation weakens the chimney structure and promotes leaks.

- Rainwater Retention

Debris accumulation, such as leaves, nests, or fallen branches, obstructs the flue and prevents proper drainage of rainwater. This retained water saturates the chimney, leading to leaks and structural damage. A bird’s nest blocking the flue can trap rainwater, causing it to seep through mortar joints and into the interior of the building. Removing obstructions ensures unimpeded drainage and reduces water exposure.

- Increased Freeze-Thaw Cycle Damage

Water trapped within the flue due to obstructions undergoes repeated freeze-thaw cycles, expanding and contracting within the masonry. This cyclical stress causes cracks and spalling, weakening the chimney and creating pathways for water intrusion. For example, ice dams forming within a blocked flue exacerbate cracking and deterioration of the masonry. Clear flues mitigate water retention, reducing the impact of freeze-thaw cycles.

- Compromised Ventilation and Draft

Obstructions disrupt the chimney’s ventilation, reducing draft and leading to inefficient combustion. This incomplete combustion results in increased moisture production, further contributing to condensation and potential leaks. A blocked flue restricts airflow, causing smoke to back up into the living space and increasing moisture levels within the chimney. Maintaining a clear flue ensures proper ventilation and reduces moisture-related damage.

The interplay between flue obstructions and chimney leaks underscores the importance of regular chimney inspections and cleaning. Removing debris and ensuring an unobstructed flue minimizes water retention, reduces condensation buildup, and prevents structural damage. Addressing flue obstructions is a critical step in maintaining a dry, safe, and efficient chimney system, mitigating the risks associated with water intrusion and associated problems.

5. Water Source Identification

Accurate identification of the source of water intrusion is a foundational step in effectively addressing chimney leaks. Failure to pinpoint the origin of the leak often results in misdirected repairs, persistent problems, and continued structural damage. Determining the source necessitates a comprehensive assessment of the chimney system and its surrounding environment to differentiate between various potential entry points.

For example, water infiltration might originate from deteriorated flashing at the roofline interface, allowing rainwater to track down the exterior masonry. Alternatively, a cracked chimney crown may permit direct water entry into the flue, bypassing the exterior altogether. Condensation within the flue, exacerbated by a blocked chimney or inefficient appliance, can also manifest as a leak, mimicking external water sources. Distinguishing between these sources requires careful examination of the chimney’s physical condition, the pattern of water staining, and the performance of connected appliances. In practice, a homeowner experiencing interior water damage near the chimney might mistakenly assume a roof leak, overlooking a cracked crown that is the true source of the problem. Only through thorough inspection can the correct origin be identified and targeted for remediation.

Ultimately, successful mitigation of chimney leaks relies heavily on accurate source identification. A systematic approach, combining visual inspection, diagnostic testing, and an understanding of chimney system dynamics, enables effective repair strategies and prevents recurring water damage. Neglecting this crucial diagnostic step increases the likelihood of ineffective repairs and continued deterioration, underscoring the importance of expertise and precision in addressing water intrusion issues.

Frequently Asked Questions

The following questions and answers address common concerns and misconceptions surrounding water intrusion issues affecting chimneys.

Question 1: What are the primary indicators of a water issue?

Common signs include water stains on interior walls or ceilings near the chimney, dampness or discoloration of the chimney masonry, efflorescence (white, powdery deposits) on the exterior brickwork, and the presence of mold or mildew odors near the fireplace or connected appliances.

Question 2: How does chimney construction contribute to vulnerability?

Factors such as the type of masonry used, the quality of mortar joints, the presence of a chimney crown, and the integrity of the flashing all impact the susceptibility of a chimney to water penetration. Deterioration or defects in any of these areas can create pathways for water to enter the system.

Question 3: What are the long-term consequences?

Prolonged water exposure can lead to significant structural damage, including crumbling masonry, flue liner deterioration, and corrosion of metal components. Additionally, moisture can promote the growth of mold and mildew, posing health risks and necessitating costly remediation. Severe cases may compromise the chimney’s stability, requiring extensive repairs or even reconstruction.

Question 4: Can these issues be addressed with DIY solutions?

While some minor repairs, such as sealing small cracks in the crown, can be attempted by homeowners, most water-related problems require professional assessment and remediation. Improper repairs can exacerbate existing issues or create new ones, potentially compromising the safety and structural integrity of the chimney. Professional services provide the necessary experience and tools for a sustainable solution.

Question 5: How frequently should it be inspected for issues?

It is recommended to conduct a thorough chimney inspection at least once a year, ideally in the fall before the heating season begins. More frequent inspections may be warranted for chimneys exposed to severe weather conditions or those serving appliances that are used frequently.

Question 6: Does using the chimney contribute to leaks?

Yes. Burning fuel creates water vapor and combustion byproducts that can condense inside the chimney. If the chimney is cold or the flue is obstructed, this condensation can saturate the masonry and contribute to leaks. Burning seasoned wood and ensuring a clear flue promotes efficient venting and reduces condensation.

Effective management of these issues requires an understanding of the underlying causes and potential consequences. Routine inspections and timely repairs are critical for preventing long-term damage and maintaining a safe and efficient venting system.

The subsequent section will delve into established repair techniques and material choices for effectively addressing water intrusion and ensuring long-term chimney protection.

Conclusion

This exploration has underscored the multifaceted nature of water intrusion affecting vertical venting systems. Addressing this issue demands a comprehensive understanding of potential sources, ranging from degraded mortar and compromised flashing to obstructed flues and defective crowns. Effective remediation hinges on accurate diagnosis and the application of appropriate repair techniques, utilizing suitable materials designed for long-term resistance to environmental factors.

The implications of neglecting chimney water intrusion extend beyond mere aesthetic concerns, potentially leading to significant structural damage, health hazards, and reduced energy efficiency. Proactive inspection, timely maintenance, and professional intervention when necessary represent a prudent investment in the longevity and safety of the building. The ongoing commitment to safeguarding this critical building component remains essential for preserving structural integrity and occupant well-being.

![Exterior Chimney Siding: Protect & Beautify [Cost Guide] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Exterior Chimney Siding: Protect & Beautify [Cost Guide] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-10-300x200.jpg)