A contained outdoor heating structure combines the ambiance of an open flame with the directed exhaust of a chimney. This design facilitates the venting of smoke and particulate matter upwards, away from immediate surroundings. Examples include free-standing metal structures with integrated chimneys or permanent brick or stone constructions featuring a similar exhaust system.

The advantages of such a design include improved air quality in the immediate vicinity, reduced risk of smoke inhalation, and a more controlled burn environment. Historically, similar structures have been employed for outdoor cooking and heating in various cultures, evolving from simple fire pits to more sophisticated designs for enhanced functionality and safety.

The following sections will delve into specific design considerations, material options, safety precautions, and regulatory guidelines related to the planning, construction, and responsible use of these outdoor features.

Essential Considerations for Chimney-Equipped Outdoor Hearths

The following guidance provides critical information to consider before, during, and after the installation and use of a contained outdoor fire feature with a chimney.

Tip 1: Site Selection is Paramount: Carefully assess the location. Ensure adequate clearance from buildings, trees, and overhead structures to prevent fire hazards and comply with local regulations. Minimum distances are typically specified in building codes.

Tip 2: Material Selection Impacts Longevity: Opt for durable, heat-resistant materials such as fire-rated brick, stone, or heavy-gauge steel. These materials withstand high temperatures and prolonged exposure to the elements, extending the lifespan of the structure.

Tip 3: Proper Chimney Design is Critical: The chimney’s height and diameter must be correctly proportioned to ensure adequate draft and efficient smoke evacuation. Consult engineering specifications or professional guidance to determine optimal dimensions.

Tip 4: Implement a Spark Arrestor: A spark arrestor, typically a wire mesh screen, is essential to prevent embers from escaping the chimney and potentially igniting nearby combustible materials. Regular inspection and cleaning are necessary for effective operation.

Tip 5: Adhere to Local Regulations and Permits: Prior to construction or installation, obtain the necessary permits and ensure compliance with all applicable local ordinances and building codes. This includes fire safety regulations and zoning restrictions.

Tip 6: Establish a Safety Perimeter: Maintain a clear safety zone around the structure during operation. Keep children, pets, and flammable materials at a safe distance to prevent accidents and injuries.

Tip 7: Practice Responsible Fuel Management: Utilize seasoned firewood and avoid burning treated lumber, plastics, or other materials that produce toxic fumes. Store firewood away from the structure to minimize fire hazards.

The successful implementation of these considerations leads to a safer, more efficient, and aesthetically pleasing outdoor heating solution. Diligence in planning and execution is paramount.

The concluding section of this article will address ongoing maintenance and troubleshooting strategies for optimal long-term performance.

1. Efficient Smoke Exhaust

Efficient smoke exhaust is a primary design consideration for any outdoor fire feature incorporating a chimney. It directly impacts user comfort, air quality, and adherence to environmental regulations. The effectiveness of smoke removal dictates the usability and overall appeal of such installations.

- Chimney Height and Diameter:

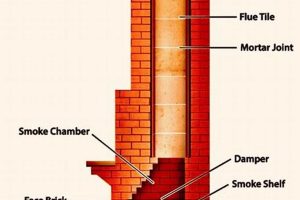

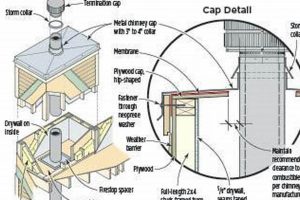

The physical dimensions of the chimney, specifically its height and diameter, directly influence the draft and thus the efficiency of smoke removal. Insufficient height can lead to poor draft, causing smoke to linger in the immediate vicinity. An improperly sized diameter can restrict airflow, similarly impairing smoke evacuation. Calculations for optimal dimensions must consider factors such as firebox size, prevailing wind conditions, and altitude.

- Draft Induction Methods:

Natural draft relies on the buoyancy of hot air to create an upward flow. However, in certain conditions, such as low ambient temperatures or unfavorable wind patterns, natural draft may be insufficient. In such cases, mechanical draft induction systems, such as electrically powered fans, can augment the airflow and ensure consistent smoke removal.

- Material Thermal Properties:

The materials used in chimney construction influence the rate at which the flue gases cool. Materials with high thermal conductivity can cause rapid cooling, reducing buoyancy and impairing draft. Conversely, materials with good insulation properties help maintain flue gas temperature, promoting efficient smoke exhaust.

- Spark Arrestor Design:

While essential for fire safety, spark arrestors can impede airflow if improperly designed or maintained. The mesh size and overall surface area of the arrestor must be carefully considered to minimize flow restriction while still effectively containing embers. Regular cleaning is necessary to prevent blockage and maintain optimal performance.

The interplay of these factors is crucial for achieving efficient smoke exhaust. A properly designed system minimizes smoke exposure for users and neighbors, reduces the risk of nuisance complaints, and contributes to a more enjoyable and responsible outdoor fire experience. A poorly designed or maintained system negates the benefits of the chimney, rendering the installation less desirable and potentially problematic.

2. Material Heat Resistance

Material heat resistance is a foundational requirement for the safe and effective operation of any contained outdoor fire feature incorporating a chimney. The extreme temperatures generated within the firebox and flue necessitate the use of materials capable of withstanding prolonged exposure to high thermal stress without structural degradation or failure.

- Structural Integrity at Elevated Temperatures

The ability of a material to maintain its mechanical strength and dimensional stability under intense heat is paramount. Materials such as firebrick, refractory cement, and high-temperature steel alloys are specifically engineered to retain their load-bearing capacity and resist deformation at temperatures exceeding 1000F. Failure to utilize such materials can result in cracking, warping, or even catastrophic collapse of the structure.

- Thermal Conductivity and Insulation Properties

The rate at which a material conducts heat influences the surface temperature of the outer structure and the potential for heat loss. Low thermal conductivity is desirable for minimizing heat transfer to surrounding materials, reducing the risk of accidental contact burns and preventing damage to nearby combustible structures. Conversely, controlled thermal conductivity can be utilized to radiate heat efficiently for warming the immediate area.

- Resistance to Thermal Shock

Rapid temperature fluctuations, such as those encountered during initial fire ignition or sudden extinguishment, can induce thermal shock in certain materials. This phenomenon occurs when differential expansion and contraction create internal stresses that lead to cracking or spalling. Materials with high thermal shock resistance, such as certain types of ceramic or composite materials, are crucial for ensuring long-term durability.

- Chemical Stability at High Temperatures

Combustion processes generate a variety of corrosive gases and particulate matter that can react with certain materials, causing degradation over time. Materials used in firebox and chimney construction must exhibit high chemical stability to resist oxidation, sulfidation, and other forms of chemical attack. Stainless steel and specialized coatings are often employed to enhance chemical resistance.

The selection of appropriate materials with high heat resistance is not merely a matter of aesthetics or convenience; it is a critical safety consideration. Proper material selection ensures structural integrity, minimizes the risk of fire hazards, and prolongs the lifespan of the fire feature, contributing to a safer and more enjoyable outdoor heating experience.

3. Structural Stability

Structural stability is a paramount concern in the design and construction of any outdoor fire feature incorporating a chimney. The persistent application of heat, combined with exposure to environmental elements, necessitates a robust and enduring structure to ensure safe and reliable operation. Compromised structural integrity can lead to hazardous conditions, including collapse, fire spread, and potential injury.

The integrity of the foundation is of utmost importance. For example, a fire pit constructed on unstable ground may shift and crack over time, compromising the chimney’s alignment and potentially causing structural failure. Similarly, the materials used in the construction of the firebox and chimney must be capable of withstanding prolonged exposure to high temperatures and thermal cycling. Firebrick, refractory mortar, and high-temperature steel are commonly employed to ensure long-term stability and resistance to thermal stress. Proper construction techniques, such as reinforced joints and adequate drainage, are also essential for preventing water damage and maintaining structural integrity.

In summary, structural stability is not merely a desirable attribute but a fundamental requirement for the safe and effective operation of an outdoor fire feature with a chimney. Neglecting this aspect can lead to severe consequences, underscoring the importance of careful design, appropriate material selection, and meticulous construction practices. A structurally sound design provides long-term safety, reliability and enjoyment.

4. Local Regulations

The implementation and operation of a chimney fire pit are directly governed by local regulations, impacting design, construction, and usage. These regulations are enacted to mitigate risks associated with open flames, smoke emissions, and potential fire hazards within a given jurisdiction. Failure to comply with such ordinances can result in fines, legal action, or the forced removal of the structure.

These regulations can encompass various aspects, including required setbacks from property lines and structures, permissible fuel types, burn bans during periods of high fire risk, and restrictions on the size and design of the fire pit itself. For example, many municipalities require a minimum distance between the fire pit and any building, fence, or overhead vegetation. Specific jurisdictions might mandate the use of spark arrestors to prevent the spread of embers. Real-life examples of non-compliance often involve complaints from neighbors regarding excessive smoke or the illegal burning of prohibited materials, leading to enforcement actions by local authorities.

Understanding and adhering to local regulations is not merely a matter of legal compliance but also a demonstration of responsible citizenship and a commitment to community safety. Prior to the installation of any such structure, it is imperative to consult with local authorities, obtain the necessary permits, and ensure that all aspects of the design and operation conform to applicable ordinances. A proactive approach to regulatory compliance mitigates risks, fosters positive community relations, and ensures the long-term enjoyment of the outdoor fire feature.

5. Proper Venting

Proper venting is an indispensable element in the design and functionality of any chimney-equipped outdoor fire feature. The effectiveness of the venting system directly influences combustion efficiency, smoke evacuation, and overall safety. A poorly designed or inadequately maintained venting system can negate the benefits of the chimney, leading to smoke inhalation, reduced heat output, and increased fire risk.

- Chimney Height and Draft

The height of the chimney directly impacts the draft, or the natural upward flow of air. Insufficient height can result in a weak draft, causing smoke to linger in the immediate vicinity. The ideal chimney height is determined by factors such as firebox size, surrounding structures, and prevailing wind conditions. Accurate calculations and adherence to building codes are critical for ensuring adequate draft.

- Flue Size and Airflow Dynamics

The cross-sectional area of the flue, or the internal passage of the chimney, must be appropriately sized to accommodate the volume of smoke and combustion gases generated by the fire. An undersized flue restricts airflow, impeding smoke evacuation and potentially leading to backdrafting. Conversely, an oversized flue can result in excessive cooling of the flue gases, reducing buoyancy and impairing draft. Optimal flue size is determined by the firebox volume and fuel type.

- Chimney Material and Thermal Properties

The material from which the chimney is constructed influences the rate at which flue gases cool. Materials with good insulation properties, such as firebrick or insulated stainless steel, help maintain the temperature of the flue gases, promoting efficient draft. Materials with high thermal conductivity can cause rapid cooling, reducing buoyancy and impairing smoke evacuation. The selection of appropriate materials is essential for optimizing venting performance.

- Obstructions and Maintenance

Accumulation of creosote, debris, or animal nests within the chimney can obstruct airflow and significantly reduce venting efficiency. Regular inspection and cleaning are essential for maintaining proper venting. Failure to remove obstructions can lead to dangerous chimney fires and the buildup of toxic gases. A proactive maintenance schedule is crucial for ensuring safe and reliable operation.

These interconnected factors highlight the critical role of proper venting in the overall performance and safety of a chimney fire pit. A well-designed and maintained venting system ensures efficient combustion, minimizes smoke exposure, and reduces the risk of fire hazards, contributing to a more enjoyable and responsible outdoor heating experience. Attention to these details is essential for maximizing the benefits of a chimney-equipped fire feature.

6. Safety Perimeter

The establishment of a defined safety perimeter is a critical component of the responsible operation of any chimney fire pit. The cause-and-effect relationship is direct: insufficient clearance around the fire pit increases the risk of accidental ignition of nearby combustible materials, leading to potential fire hazards and injuries. The safety perimeter serves as a buffer zone, minimizing the potential for uncontrolled fire spread and ensuring the well-being of individuals in the vicinity. Real-life examples underscore the importance of this precaution; instances of unattended fire pits igniting dry vegetation or causing structural damage due to proximity are well-documented. The practical significance lies in the prevention of preventable accidents and the maintenance of a safe environment for users and surrounding properties.

The dimensions of the safety perimeter should be determined based on the size of the fire pit, the height of the chimney, and the prevailing wind conditions. A general guideline suggests a minimum radius of 10 feet from the outer edge of the fire pit, but this may need to be increased depending on specific circumstances. The perimeter should be kept clear of flammable materials such as dry leaves, mulch, wooden furniture, and overhanging branches. Supervision of the fire pit is crucial, especially when children or pets are present, to prevent accidental contact with the flames or hot surfaces. Additionally, having readily accessible fire suppression equipment, such as a fire extinguisher or a water hose, is essential for responding to any unforeseen fire events.

In summary, the safety perimeter is an integral safety measure for chimney fire pits. This space should be deliberately planned and maintained to ensure a safe and enjoyable outdoor experience. Consistent enforcement of safety protocols within the perimeter, including adequate clearance from combustibles and active supervision, is crucial for mitigating fire risks and protecting individuals and property. The challenges surrounding perimeter maintenance, such as seasonal accumulation of debris, can be addressed through regular inspections and clearing. This proactive approach is essential for linking this safety aspect to the overall responsible operation of such installations.

7. Controlled Combustion

Controlled combustion is fundamental to the safe and efficient operation of a chimney fire pit. The term refers to the regulated process of burning fuel to maximize heat output while minimizing the production of smoke and harmful emissions. This is achieved through careful management of airflow, fuel type, and combustion temperature. The absence of controlled combustion results in incomplete burning, producing excessive smoke, wasted fuel, and potential safety hazards.

- Airflow Management

The introduction of oxygen is essential for combustion, but the quantity and distribution of airflow must be carefully regulated. Excessive airflow cools the fire, reducing combustion efficiency. Insufficient airflow leads to incomplete burning and increased smoke production. Chimney fire pits often incorporate adjustable vents or dampers to control airflow, allowing users to optimize combustion based on fuel type and environmental conditions. For example, during initial ignition, increased airflow can help establish a strong flame. Once the fire is established, reducing airflow can promote slower, more complete combustion.

- Fuel Selection and Preparation

The type and condition of fuel significantly impact combustion efficiency. Seasoned firewood, with a moisture content of less than 20%, burns more cleanly and efficiently than green or damp wood. Seasoned wood ignites more easily, burns at a higher temperature, and produces less smoke. Conversely, burning treated lumber, plastics, or other unsuitable materials can release toxic fumes and damage the chimney fire pit. Preparing firewood by splitting it into smaller pieces increases surface area, facilitating more rapid and complete combustion.

- Temperature Optimization

Maintaining an optimal combustion temperature is crucial for minimizing smoke production and maximizing heat output. Temperatures that are too low result in incomplete combustion and increased emissions of unburned hydrocarbons. Temperatures that are too high can lead to excessive formation of nitrogen oxides (NOx), a regulated pollutant. The design of the firebox and chimney, including insulation and airflow characteristics, influences combustion temperature. Proper fuel loading and airflow management can help maintain the fire within the optimal temperature range.

- Chimney Design and Draft

The design of the chimney plays a critical role in facilitating controlled combustion. The chimney’s height and diameter influence the draft, or the natural upward flow of air, which is essential for drawing in oxygen and expelling smoke and combustion gases. An inadequately sized or poorly designed chimney can restrict airflow, leading to incomplete combustion and increased smoke production. A well-designed chimney promotes efficient combustion and helps to maintain a stable and predictable burn pattern.

These facets of controlled combustion are inextricably linked in the context of a chimney fire pit. Optimizing airflow, selecting appropriate fuel, maintaining optimal combustion temperature, and ensuring proper chimney design work in concert to achieve efficient, clean, and safe burning. Neglecting any of these aspects can compromise combustion efficiency, increase smoke production, and potentially create hazardous conditions. Therefore, a thorough understanding of these principles is essential for the responsible and effective use of a chimney fire pit.

Frequently Asked Questions

The following addresses common inquiries regarding the construction, operation, and safety of outdoor fire features incorporating a chimney.

Question 1: What materials are suitable for constructing a structure?

Acceptable materials include fire-rated brick, stone, and heavy-gauge steel. These substances exhibit high heat resistance and structural integrity at elevated temperatures.

Question 2: How does the chimney height influence performance?

The height of the chimney directly impacts the draft, or natural upward airflow. Insufficient height can result in poor smoke evacuation. Consult local regulations and engineering specifications to determine optimal dimensions.

Question 3: Is a spark arrestor a mandatory component?

A spark arrestor is essential for preventing embers from escaping and potentially igniting nearby combustible materials. Regular inspection and cleaning are necessary for effective operation.

Question 4: What are common signs of improper combustion?

Indicators of inefficient combustion include excessive smoke production, difficulty igniting the fire, and a lack of sustained heat output. These issues may stem from improper fuel selection, inadequate airflow, or chimney obstructions.

Question 5: How often should the chimney be inspected and cleaned?

The chimney should be inspected at least annually and cleaned as needed to remove creosote buildup and other obstructions. The frequency of cleaning depends on usage patterns and fuel type.

Question 6: What safety precautions should be observed during operation?

A clear safety perimeter should be maintained around the structure. Flammable materials should be kept at a safe distance, and the fire should never be left unattended. A readily accessible fire extinguisher or water source is also recommended.

Adherence to these guidelines promotes safe and responsible utilization. Consulting local authorities and qualified professionals is advisable prior to construction or operation.

The subsequent section will address advanced topics related to design optimization and performance enhancement.

Chimney Fire Pit

This discourse has elucidated the multifaceted nature of the chimney fire pit, encompassing design parameters, material selection, safety protocols, and regulatory compliance. It emphasizes the imperative of adhering to established guidelines to ensure both optimal functionality and the mitigation of potential hazards associated with open-flame combustion.

The responsible integration of this feature into outdoor environments necessitates a commitment to informed decision-making and meticulous execution. The enduring value of a chimney fire pit lies not only in its aesthetic appeal but, more fundamentally, in its capacity to provide a safe and controlled source of warmth and ambiance when approached with diligence and foresight.