Vertical structures designed to vent combustion gases and smoke from a fireplace, furnace, or other heating appliance are categorized based on materials, construction methods, and intended applications. These structures facilitate the safe and efficient removal of byproducts from heating processes, contributing to indoor air quality and preventing hazardous buildup within a building. Examples include masonry units, prefabricated metal components, and factory-built systems.

The implementation of appropriately designed venting systems is critical for ensuring the operational safety and efficiency of heating appliances. Throughout history, these systems have evolved from rudimentary constructions to sophisticated engineered solutions, reflecting advancements in material science and combustion technology. Correct implementation mitigates fire hazards, reduces carbon monoxide exposure, and optimizes fuel consumption.

The ensuing discussion will delve into the distinct classifications of these ventilation structures, examining the specific characteristics, advantages, and limitations associated with each variety. Attention will be given to factors influencing selection, including building codes, appliance compatibility, and environmental considerations.

Guidance on Chimney System Selection

Proper selection and maintenance of vertical venting systems are paramount for safety and efficiency in residential and commercial heating applications. Adherence to established guidelines can mitigate risks and prolong system lifespan.

Tip 1: Consider Fuel Type Compatibility: Ensure the structure is designed and rated for the specific fuel burned. Solid fuel systems require different construction materials and flue dimensions than gas or oil-burning systems due to variations in combustion temperatures and byproducts.

Tip 2: Adhere to Local Building Codes: Compliance with municipal and regional codes is mandatory. These regulations dictate height requirements, clearances to combustible materials, and permissible materials based on local climate and fire safety standards.

Tip 3: Prioritize Professional Installation: Engage certified professionals for installation and inspection. Improper installation can lead to hazardous conditions, including flue gas leaks and structural instability. A qualified technician will ensure proper sizing, sealing, and securement.

Tip 4: Conduct Regular Inspections: Schedule routine inspections by a qualified professional, ideally annually. Inspections identify structural damage, creosote buildup, and potential obstructions that can compromise system performance and safety.

Tip 5: Maintain Adequate Clearance to Combustibles: Maintain the required clearances from combustible materials, such as wood framing and insulation. Insufficient clearance can lead to ignition and structural fires. Refer to manufacturer specifications and local building codes for minimum clearance requirements.

Tip 6: Ensure Proper Draft: Proper draft is essential for efficient combustion and venting. Factors affecting draft include height, flue diameter, and chimney location. Insufficient draft can result in backdrafting and carbon monoxide poisoning.

Tip 7: Address Water Intrusion Promptly: Water penetration can damage the structure and accelerate deterioration. Implement preventative measures such as installing a chimney cap and ensuring proper flashing around the roof penetration.

Following these guidelines enhances safety, optimizes heating appliance performance, and extends the service life of the vertical venting structure. Neglecting these precautions can result in significant safety hazards and costly repairs.

The subsequent sections of this document will further explore specific construction techniques and maintenance procedures relevant to different classes of vertical venting systems.

1. Material Composition

Material composition fundamentally defines the performance characteristics, longevity, and compatibility of structures designed for exhausting combustion byproducts. The specific materials employed directly impact a system’s ability to withstand high temperatures, corrosive gases, and environmental stressors, thus influencing its suitability for different applications and fuel types.

- Masonry Construction

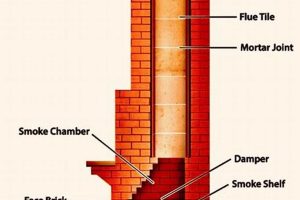

Traditional masonry utilizes brick, stone, or concrete blocks, often combined with a refractory liner, to create a robust structure. These systems exhibit excellent thermal mass, providing slow heat release and mitigating rapid temperature fluctuations. However, masonry is susceptible to cracking due to thermal expansion and contraction, and requires periodic inspection and repair. The weight and labor-intensive installation are also significant considerations.

- Metal Systems

Metal structures, typically constructed from stainless steel or galvanized steel, offer lightweight construction and relatively easy installation. These are generally prefabricated and designed for specific appliances and fuel types. Stainless steel provides superior corrosion resistance compared to galvanized steel, extending its service life, especially in applications involving acidic combustion gases. Metal systems tend to heat up and cool down more quickly than masonry, potentially affecting draft characteristics.

- Factory-Built Systems

Factory-built systems represent a hybrid approach, often incorporating both metal and ceramic components. These systems are engineered for specific performance criteria and are typically listed and labeled to meet stringent safety standards. They offer advantages in terms of ease of installation, predictable performance, and compliance with building codes. However, their modular design may limit flexibility in certain installations, and replacement components may be proprietary.

- Composite Materials

Emerging composite materials, such as fiber-reinforced polymers, are being explored for their potential to offer lightweight, corrosion-resistant alternatives. While currently less prevalent than traditional materials, these composites may offer advantages in specific applications where weight and resistance to chemical attack are paramount. Their long-term durability and performance under high-temperature conditions are areas of ongoing research and evaluation.

The selection of material composition directly influences the overall performance, safety, and longevity of the chosen system. Understanding the properties and limitations of each material type is critical for ensuring compatibility with the intended appliance, fuel type, and environmental conditions, thereby optimizing system performance and minimizing potential hazards.

2. Construction Method

The method of construction significantly determines the structural integrity, thermal performance, and overall lifespan of structures designed for venting combustion byproducts. Distinct construction techniques are employed depending on the selected materials, intended application, and prevailing building codes. These techniques directly influence a system’s ability to safely and efficiently exhaust flue gases.

- Mortared Masonry Construction

This method involves assembling brick, stone, or concrete blocks with mortar to create a durable and fire-resistant structure. Reinforcement with steel bars is sometimes incorporated to enhance structural stability, particularly in regions prone to seismic activity. Mortar joints are critical to preventing flue gas leakage and must be carefully maintained. This technique is labor-intensive and requires skilled craftsmanship to ensure proper construction and alignment.

- Prefabricated Modular Assembly

Prefabricated systems consist of factory-produced components that are assembled on-site. These components typically include metal flues, insulation materials, and outer casings. This method offers faster installation times and greater consistency in quality control compared to traditional masonry. However, the modular design may limit design flexibility, and compatibility with specific appliances must be carefully verified.

- Cast-in-Place Concrete

This technique involves pouring concrete into a formwork to create a monolithic structure. This method can provide exceptional structural strength and resistance to fire. However, it requires specialized equipment and expertise, and the curing process can be time-consuming. Cast-in-place construction is often employed in large commercial or industrial applications where durability is paramount.

- Slip Lining

Slip lining is a construction method primarily used for chimney repair and restoration, rather than new construction. It involves inserting a new liner, typically made of stainless steel or flexible polymer, inside an existing damaged masonry. This method restores the structure’s integrity and improves its venting efficiency without requiring complete reconstruction. Slip lining is a cost-effective solution for addressing deteriorated or undersized systems.

Each construction method presents distinct advantages and limitations concerning cost, installation time, structural performance, and compatibility with different fuel types. The selection of an appropriate construction technique must consider these factors to ensure a safe, efficient, and durable venting system.

3. Venting Function

The primary function of a vertical exhaust system is to safely and efficiently remove combustion byproducts from heating appliances, ensuring proper air quality and preventing hazardous accumulations. The design and construction of these structures are intrinsically linked to their intended venting function, dictating the selection of appropriate materials, dimensions, and configurations.

- Draft Creation and Maintenance

Effective venting relies on establishing and maintaining a stable draft, a pressure differential that draws combustion gases upwards and out of the structure. The height, cross-sectional area, and interior surface characteristics of the unit directly influence draft strength. Insufficient draft can lead to backdrafting, resulting in dangerous accumulation of carbon monoxide and other noxious gases within the occupied space. For instance, taller structures generally produce a stronger draft, while oversized flues can result in insufficient draft.

- Containment and Conduction of Flue Gases

The structural integrity of the unit is paramount for containing and safely conducting hot, corrosive flue gases to the atmosphere. Materials must be resistant to high temperatures, acidic condensation, and creosote buildup. Cracks or leaks in the structure can compromise its ability to contain gases, leading to fire hazards and indoor air pollution. Masonry systems, metal flues, and factory-built components each offer distinct advantages and disadvantages in terms of containment capabilities.

- Regulation of Exhaust Gas Temperature

The rate at which exhaust gases cool as they ascend through the system significantly affects venting efficiency. Rapid cooling can lead to condensation, which can damage the structure and impede draft. Conversely, excessively high temperatures can pose a fire hazard if the structure is not properly insulated. The design must balance heat retention and dissipation to optimize venting performance and minimize the risk of condensation or overheating. For example, insulated metal flues help maintain exhaust gas temperature, preventing condensation and promoting a stronger draft.

- Protection Against Environmental Factors

The external design of the system must protect against environmental factors such as wind, rain, and snow. Proper termination, including the use of chimney caps and spark arrestors, prevents downdrafts, water intrusion, and the escape of embers. Wind-induced pressure variations can disrupt draft and lead to backdrafting, while water penetration can damage the structure and accelerate deterioration. A well-designed termination minimizes these risks and ensures consistent venting performance, especially in areas with severe weather conditions.

These facets underscore the critical role of venting function in determining the design and performance characteristics of vertical exhaust systems. The selection of appropriate construction materials, dimensions, and termination methods is essential for ensuring safe, efficient, and reliable removal of combustion byproducts.

4. Code Adherence

The selection and installation of vertical venting systems are fundamentally governed by stringent building codes designed to ensure public safety and structural integrity. Code adherence mandates that the chosen system meets specific performance criteria, material standards, and installation requirements as dictated by local, regional, and national regulations. Failure to comply with these codes can result in significant safety hazards, including fire risks, carbon monoxide poisoning, and structural damage, as well as legal and financial repercussions.

The type of system selected directly dictates the applicable code requirements. For example, masonry structures must adhere to specific standards for brick or block composition, mortar strength, and flue liner installation. Metal systems, on the other hand, are typically subject to listing and labeling requirements, ensuring they have been tested and certified to meet specific performance standards. Fuel type also plays a crucial role in code compliance, as systems designed for solid fuels (e.g., wood) have different code requirements than those intended for gas or oil. The National Fire Protection Association (NFPA) provides comprehensive standards for venting systems, which are often adopted or referenced by local building codes.

Understanding the intimate relationship between system selection and code requirements is paramount for homeowners, contractors, and building inspectors. Proper code adherence not only mitigates safety risks but also ensures the longevity and efficient operation of the heating appliance. Regular inspections and maintenance, as prescribed by code, are essential for maintaining compliance and preventing potential hazards. Neglecting code requirements can have severe consequences, underscoring the importance of consulting with qualified professionals and adhering to all applicable regulations throughout the design, installation, and maintenance phases.

5. Required Maintenance

The type of vertical venting system installed directly dictates the required maintenance schedule and procedures. Masonry structures, metal flues, and factory-built components each exhibit unique vulnerabilities necessitating tailored maintenance practices. Understanding these differences is crucial for ensuring system safety and longevity. Neglecting appropriate maintenance protocols increases the risk of fire hazards, structural deterioration, and reduced venting efficiency. For instance, creosote accumulation is a significant concern in systems serving wood-burning appliances, requiring regular inspection and removal to prevent chimney fires. Similarly, metal flues are susceptible to corrosion, necessitating periodic examination for rust and degradation, particularly in environments with high humidity or acidic combustion byproducts.

Maintenance activities commonly include inspection, cleaning, and repair. Inspection involves a thorough assessment of the system’s structural integrity, flue condition, and termination. Cleaning removes accumulated creosote, soot, and debris that can obstruct airflow and increase fire risk. Repairs address any identified structural damage, such as cracked masonry, corroded metal, or deteriorated mortar joints. The frequency of these activities varies depending on the appliance type, fuel used, and system design. For example, systems connected to frequently used wood-burning stoves may require cleaning several times per year, while those serving gas furnaces may only need annual inspections. Improper maintenance, such as using the wrong cleaning tools or neglecting necessary repairs, can exacerbate existing problems and compromise system safety. A practical example is attempting to clean a metal flue with abrasive tools, which can damage the protective coating and accelerate corrosion.

In summary, the type of vertical exhaust system significantly influences the scope and frequency of required maintenance. Regular inspection, cleaning, and repair are essential for ensuring system safety, efficiency, and longevity. Understanding these connections is critical for homeowners and professionals alike, enabling them to implement appropriate maintenance practices and mitigate potential hazards. Challenges include accessing difficult-to-reach areas and accurately assessing the condition of internal components. Properly maintaining these venting structures directly supports the broader goal of safe and efficient heating practices.

6. Fuel Compatibility

The selection of a particular type of vertical exhaust system is fundamentally intertwined with the fuel type it is intended to vent. Incompatible pairings can result in accelerated deterioration, compromised safety, and inefficient operation. Consideration of fuel characteristics and combustion byproducts is essential for ensuring a safe and durable venting system.

- Solid Fuel Systems and High Temperatures

Solid fuels, such as wood and coal, generate significantly higher flue gas temperatures compared to gas or oil. Systems venting solid fuels require robust construction with high-temperature-resistant materials like refractory-lined masonry or listed, high-temperature metal components. Failure to employ appropriate materials can lead to premature failure, cracking, and increased risk of chimney fires due to creosote buildup. For example, a single-wall metal flue improperly used with a wood-burning stove can quickly overheat, posing a serious fire hazard.

- Gas Appliances and Condensation Concerns

High-efficiency gas appliances produce cooler flue gases, increasing the likelihood of condensation within the venting system. This condensation can be highly acidic, leading to corrosion of metallic components, particularly in older, unlined masonry. Systems designed for gas appliances often incorporate corrosion-resistant materials like stainless steel or specialized liners to mitigate the effects of acidic condensate. For instance, an unlined masonry flue connected to a modern condensing furnace can experience rapid deterioration due to condensate penetration.

- Oil-Burning Systems and Sulfur Dioxide Exposure

Oil-burning appliances generate flue gases containing sulfur dioxide, which can react with moisture to form sulfuric acid. This acid can corrode metal systems and degrade masonry components, leading to structural damage and flue gas leakage. Systems venting oil-burning appliances benefit from acid-resistant materials and regular inspection to identify and address corrosion issues promptly. An example of this is the degradation of mortar joints in older brick structures venting oil furnaces.

- Ventilation and Dilution Strategies

Some systems incorporate ventilation and dilution strategies to reduce the concentration of corrosive byproducts and lower flue gas temperatures. These strategies involve introducing outside air into the venting system to dilute the combustion gases, which can reduce condensation and corrosion. However, these strategies must be carefully engineered to avoid compromising draft or increasing the risk of backdrafting. A power-vented system connected to a high-efficiency furnace is a real-world application of a ventilation and dilution strategy.

In conclusion, the selection of a system must align with the specific fuel type and combustion characteristics to ensure safe, efficient, and durable operation. Each fuel presents unique challenges, requiring careful consideration of material compatibility, temperature resistance, and corrosion protection. Adherence to building codes and manufacturer recommendations is essential for preventing potential hazards and maximizing the lifespan of the venting system.

7. Safety Features

The integration of safety features within vertical exhaust systems is paramount in mitigating inherent risks associated with combustion processes. The specific safety mechanisms employed vary considerably based on construction materials, system design, and intended fuel type. Selection and proper maintenance of these features directly impact the overall safety and operational integrity of the installation.

- Spark Arrestors

Spark arrestors are screens designed to prevent the escape of embers and sparks from the chimney termination. They are particularly crucial for systems serving solid fuel appliances, where the potential for airborne sparks is significantly higher. These arrestors reduce the risk of igniting nearby combustible materials, such as roofing or vegetation. Regular cleaning is essential to prevent blockage, which can impede draft. Failure to maintain a spark arrestor can negate its intended safety function, increasing the likelihood of fire ignition.

- Chimney Caps

Chimney caps serve multiple safety functions, including preventing water intrusion, excluding animals and debris, and mitigating downdrafts caused by wind. Water penetration can damage the structure and accelerate deterioration. Animal nests and debris can obstruct the flue, leading to backdrafting and carbon monoxide poisoning. Properly sized and installed caps are crucial for maintaining safe and efficient operation. Inadequate caps can compromise the structural integrity and safety of the venting system.

- Cleanout Doors

Cleanout doors provide access to the base of the chimney flue for inspection and removal of accumulated ash, creosote, and debris. Regular cleaning is essential for preventing flue blockages and reducing the risk of chimney fires. Accessible and properly sealed cleanout doors are critical for effective maintenance. Neglecting to clean the base of the system can lead to restricted airflow and hazardous conditions.

- Draft Regulators

Draft regulators, also known as barometric dampers, are designed to maintain a consistent draft within the system by automatically adjusting the amount of air entering the flue. This is particularly important for appliances that are sensitive to variations in draft, such as oil-burning furnaces. Stable draft prevents backdrafting and ensures efficient combustion. Improperly adjusted or malfunctioning draft regulators can compromise combustion efficiency and increase the risk of carbon monoxide exposure.

These safety features represent essential components in ensuring the safe and reliable operation of vertical exhaust systems. Their proper selection, installation, and maintenance are critical for mitigating inherent risks and maintaining the structural integrity of the system. Disregarding these features can have severe safety implications, underscoring the importance of diligent adherence to industry best practices and building code requirements.

Frequently Asked Questions

This section addresses common inquiries regarding various classifications of vertical venting structures. The information provided is intended to offer clarity and insight into the selection, maintenance, and safe operation of these systems.

Question 1: What factors determine the selection of an appropriate unit for a given application?

The selection process necessitates careful consideration of several interconnected factors. These include the type of appliance being vented, the fuel utilized, local building codes, the climate, and the structural characteristics of the building. An undersized or incompatible system can lead to hazardous conditions.

Question 2: How frequently should systems be inspected and cleaned?

Inspection frequency depends largely on fuel type and usage patterns. Systems serving solid-fuel appliances, such as wood-burning stoves, generally require more frequent inspections, potentially as often as every three months during periods of heavy use. Gas- and oil-burning systems typically benefit from annual inspections. Cleaning should be performed as needed based on the findings of these inspections.

Question 3: What are the primary dangers associated with neglecting maintenance?

Neglecting required maintenance significantly increases the risk of chimney fires, carbon monoxide poisoning, and structural damage. Accumulations of creosote, soot, and debris can obstruct airflow, leading to backdrafting and reduced heating efficiency. Deterioration of the system’s structure can compromise its ability to contain flue gases, resulting in leaks and potential fire hazards.

Question 4: Can an existing structure be adapted to accommodate a different fuel type?

Adapting an existing structure to accommodate a different fuel type is often complex and may not be feasible without significant modifications. The existing system may not be adequately sized or constructed to handle the different combustion characteristics of the new fuel. Consult with a qualified professional to assess the feasibility and safety of such conversions.

Question 5: What distinguishes masonry structures from prefabricated metal systems?

Masonry units are constructed on-site using brick, stone, or concrete blocks, offering durability and thermal mass. Prefabricated metal systems are manufactured in a factory and assembled on-site, providing ease of installation and consistent performance. Metal systems tend to heat up and cool down more rapidly, while masonry structures offer greater heat retention.

Question 6: How important is professional installation and inspection?

Professional installation and inspection are critical for ensuring the safety and proper functioning of vertical venting systems. Qualified professionals possess the knowledge and expertise to select the appropriate system, install it according to code requirements, and identify potential hazards. Improper installation or inadequate inspection can lead to dangerous and costly consequences.

In summary, responsible ownership of any heating appliance necessitates a thorough understanding of the associated venting system and diligent adherence to recommended maintenance practices.

The subsequent discussion will transition to explore emerging technologies and future trends in system design and functionality.

Conclusion

The preceding exploration has detailed the crucial variations among chimney types, emphasizing their distinct characteristics, applications, and maintenance needs. Selection of the appropriate system necessitates a comprehensive understanding of fuel compatibility, code adherence, and safety features to ensure effective and safe venting of combustion byproducts.

Given the integral role these structures play in safeguarding property and health, diligent adherence to established guidelines and professional consultation are paramount. Ongoing diligence in inspection and maintenance will ensure the continued integrity and optimal performance of these essential building components, mitigating potential hazards and promoting responsible heating practices.