The visible emission originating from a vertical structure designed to expel combustion byproducts is comprised of particulate matter, gases, and water vapor. This discharge is a consequence of burning fuel sources within a contained area for heating, power generation, or industrial processes. The observable plume serves as a direct indicator of combustion activity and the efficiency of the process within.

The characteristics of this effluent provide insights into operational efficiency and environmental impact. Historically, the control and management of such emissions have been central to public health and environmental regulations. Reductions in particulate matter and harmful gases lead to improved air quality and minimized risks associated with respiratory illnesses and ecological damage. Efficient fuel combustion minimizes release, optimizing resource utilization and lessening the carbon footprint.

Subsequent sections detail the composition of these emissions, methods for mitigating their environmental impact, and the regulatory frameworks governing their release. Emphasis will be placed on advancements in combustion technologies and emission control systems aimed at achieving cleaner and more sustainable operational practices. Discussions surrounding public perception and policy considerations will also be addressed.

Mitigation Strategies for Emissions

Effective management of effluent originating from combustion processes necessitates proactive strategies to minimize environmental impact and ensure regulatory compliance. The following guidelines present fundamental approaches for reducing the visible plume and its associated pollutants.

Tip 1: Optimize Fuel Combustion: Implement combustion control systems to ensure complete fuel oxidation. Regular maintenance of burners and related equipment is crucial for efficient burning, minimizing unburnt fuel and particulate matter.

Tip 2: Employ Emission Control Technologies: Invest in technologies such as scrubbers, electrostatic precipitators, and catalytic converters. These devices capture or neutralize pollutants before they are released into the atmosphere.

Tip 3: Utilize Cleaner Fuel Sources: Transition to fuels with lower sulfur content and reduced particulate-forming potential. Natural gas, propane, and biofuels present alternatives to traditional fossil fuels, resulting in fewer harmful emissions.

Tip 4: Implement Regular Monitoring: Establish a consistent monitoring program to track emission levels and identify potential operational inefficiencies. Data analysis facilitates timely adjustments to combustion processes and emission control systems.

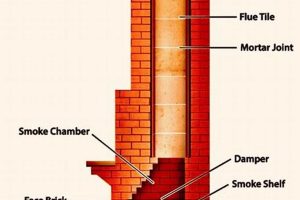

Tip 5: Maintain Chimney Integrity: Ensure the structural integrity of the vertical discharge structure to optimize draft and dispersion. Blockages or damage can impede proper ventilation and contribute to localized pollution.

Tip 6: Adhere to Regulatory Standards: Maintain strict compliance with all applicable environmental regulations and permitting requirements. Staying informed about evolving standards and implementing necessary adjustments is vital.

Tip 7: Conduct Energy Audits: Perform periodic energy audits to identify opportunities for reducing fuel consumption and improving overall efficiency. Minimizing energy usage directly translates to lower emissions.

These recommendations underscore the importance of proactive strategies in controlling and mitigating the environmental impact stemming from combustion processes. By implementing these guidelines, operators can significantly reduce emissions, improve air quality, and contribute to a more sustainable environment.

The concluding sections will delve into case studies illustrating successful emission reduction initiatives and explore future trends in cleaner combustion technologies. Further considerations will be given to the economic factors involved.

1. Combustion Byproducts

Combustion byproducts represent the direct consequence of burning fuel within a system, fundamentally defining the composition and characteristics of visible emissions from a vertical discharge structure. The specific constituents and their relative proportions dictate the environmental and health implications associated with these emissions.

- Particulate Matter (PM)

PM consists of solid and liquid particles suspended in the air. Sources range from incomplete combustion to ash. Fine particulate matter (PM2.5) poses a significant health risk due to its ability to penetrate deep into the respiratory system. The concentration of PM directly influences the visibility and opacity of the emitted plume. Regulations often target PM emissions to improve air quality.

- Gaseous Pollutants

Gaseous pollutants, including carbon monoxide (CO), sulfur dioxide (SO2), and nitrogen oxides (NOx), are formed during combustion. CO results from incomplete fuel oxidation, while SO2 arises from sulfur-containing fuels. NOx forms under high-temperature conditions. These gases contribute to acid rain, respiratory problems, and smog formation. Emission control technologies, such as scrubbers and catalytic converters, aim to reduce these pollutants.

- Water Vapor

Water vapor is a natural byproduct of hydrocarbon combustion. The amount of water vapor emitted is dependent on the fuel composition and combustion efficiency. In cold ambient conditions, water vapor condenses, contributing to the visible plume. While water vapor itself is not typically considered a pollutant, its presence can influence the dispersion of other pollutants.

- Unburnt Hydrocarbons

Unburnt hydrocarbons represent fuel that did not completely combust during the burning process. These compounds can contribute to smog formation and pose health risks. Efficient combustion systems minimize the emission of unburnt hydrocarbons through optimized air-fuel ratios and proper temperature control. Regular maintenance of combustion equipment is crucial in reducing these emissions.

These byproducts, collectively, determine the nature and potential impact of emissions. Understanding their sources, characteristics, and interactions is crucial for developing effective strategies to mitigate environmental and health risks associated with emissions from vertical structures designed to expel combustion products. The presence and quantity of these products serve as a gauge of combustion efficiency and environmental responsibility.

2. Air pollutant dispersion

The trajectory and concentration of effluent following its release from a vertical discharge structure are governed by atmospheric processes collectively termed “air pollutant dispersion.” The height of the structure, wind speed and direction, atmospheric stability, and terrain characteristics directly influence this dispersion. Insufficient dispersion results in localized pollutant accumulation, exacerbating air quality concerns and potential health impacts within the immediate vicinity.

The effectiveness of dispersion strategies is critical in minimizing pollution. For example, taller stacks increase the initial momentum and buoyancy of the plume, allowing for greater mixing with ambient air and reducing ground-level concentrations. Meteorological conditions, such as temperature inversions, can impede dispersion, leading to elevated pollutant levels near the source. Predictive modeling techniques are utilized to assess potential dispersion patterns and inform the design and operation of emissions systems.

Proper understanding of air pollutant dispersion dynamics is vital for responsible emissions management. Failing to account for these factors can lead to non-compliance with air quality regulations and adverse health consequences. Comprehensive assessments that integrate meteorological data, source characteristics, and dispersion models are necessary to optimize emission control strategies and safeguard public health.

3. Fuel source variations

The type of fuel combusted directly determines the composition of emissions released. Different fuels contain varying levels of carbon, sulfur, nitrogen, and other elements, which, upon combustion, transform into distinct pollutants. For instance, burning coal, particularly coal with a high sulfur content, releases significant amounts of sulfur dioxide (SO2), a major contributor to acid rain and respiratory problems. In contrast, natural gas combustion typically produces fewer SO2 emissions but can still generate nitrogen oxides (NOx), depending on combustion temperature and conditions. Wood combustion results in particulate matter emissions, including fine particles (PM2.5) that pose significant health risks. The selection of fuel, therefore, profoundly influences the nature and quantity of pollutants found in a vertical discharge plume.

Industrial facilities demonstrate this principle in practice. Power plants that have transitioned from coal to natural gas observe a marked reduction in SO2 and particulate matter emissions, contributing to improved air quality. Residential heating systems relying on wood-burning stoves or furnaces generate localized air pollution, particularly during cold weather months when usage is high. Biomass combustion, while often considered a renewable energy source, can release substantial amounts of particulate matter if not conducted with advanced combustion technologies. Understanding these fuel-specific emission profiles is crucial for implementing targeted pollution control strategies and mitigating their environmental impacts.

In conclusion, fuel source variation stands as a critical determinant of the composition. Recognizing the distinct emission characteristics associated with each fuel type enables informed decision-making regarding fuel selection, combustion technology deployment, and emissions control strategies. The challenge lies in promoting the adoption of cleaner fuels and combustion technologies to minimize the environmental and health burdens associated with vertical discharge emissions, underscoring the practical significance of this understanding.

4. Thermal Inversion Effects

Thermal inversions represent atmospheric conditions wherein a layer of warm air traps cooler air beneath it, deviating from the normal temperature gradient. This phenomenon significantly impacts the dispersion of emissions, exacerbating air pollution, particularly in areas with sources expelling combustion byproducts through vertical structures.

- Trapped Pollutants

Under normal atmospheric conditions, pollutants emitted from combustion processes rise and disperse, diluting their concentration. During a thermal inversion, the warm air layer acts as a lid, preventing the pollutants from rising and dispersing. This leads to a concentration of pollutants near the ground, increasing the potential for adverse health effects. For instance, cities located in valleys or basins are particularly susceptible to thermal inversions, trapping emissions and creating smog.

- Increased Ground-Level Concentrations

The accumulation of pollutants during a thermal inversion results in elevated ground-level concentrations of particulate matter, sulfur dioxide, nitrogen oxides, and other harmful substances. These high concentrations can trigger respiratory problems, cardiovascular issues, and other health complications, especially among vulnerable populations such as children, the elderly, and individuals with pre-existing respiratory conditions. The increased pollutant levels can also damage vegetation and materials.

- Smog Formation

Thermal inversions contribute to the formation of smog, a visible haze composed of air pollutants. Smog reduces visibility, degrades air quality, and poses health risks. Photochemical smog, formed by the interaction of sunlight with pollutants such as nitrogen oxides and volatile organic compounds, is particularly prevalent during thermal inversions. The stagnation of air during an inversion allows these reactions to proceed, leading to the formation of ozone and other secondary pollutants.

- Prolonged Exposure

Thermal inversions can persist for several hours or even days, leading to prolonged exposure to elevated pollutant concentrations. This extended exposure increases the risk of both acute and chronic health effects. During prolonged inversions, air quality advisories may be issued, urging individuals to limit outdoor activities and take precautions to protect their health. The duration of the inversion directly correlates with the severity of the resulting pollution and associated health impacts.

The confluence of thermal inversions and emission sources creates a scenario of heightened environmental risk, necessitating vigilant monitoring, proactive mitigation strategies, and responsible emissions management to safeguard air quality and public health. Regions with frequent inversions must prioritize measures to reduce emissions and minimize the impacts of these atmospheric events.

5. Chimney height influence

The height of a vertical discharge structure significantly affects the dispersion and concentration of emissions. A taller structure facilitates greater plume rise, allowing combustion byproducts to mix with ambient air at higher altitudes. This process reduces ground-level concentrations of pollutants, mitigating potential adverse health effects and environmental impacts. Conversely, a shorter structure results in lower plume rise, concentrating emissions closer to the ground and potentially exacerbating localized air pollution problems. The design and implementation of vertical discharge systems must, therefore, consider height as a critical parameter in managing emission dispersion.

Regulations governing emissions from industrial facilities and residential heating systems often mandate minimum chimney heights to ensure adequate pollutant dispersion. For instance, power plants and manufacturing facilities are typically required to construct tall stacks to minimize ground-level concentrations of sulfur dioxide and particulate matter. Similarly, local building codes may specify minimum chimney heights for wood-burning stoves to reduce the risk of indoor and outdoor air pollution. Computational fluid dynamics (CFD) modeling can be used to simulate plume dispersion from structures of varying heights, aiding in the determination of optimal chimney dimensions for specific emission sources and environmental conditions.

In summary, the height of a vertical emission structure functions as a primary determinant of pollutant dispersion and ground-level concentrations. Careful consideration of height during the design and implementation phases is essential for mitigating air pollution and safeguarding public health. Adherence to regulatory standards and the use of modeling techniques can ensure effective dispersion of emissions and minimize environmental impacts, underscoring the practical significance of understanding this relationship.

6. Particulate matter analysis

Examination of particulate matter extracted from vertical discharge emissions provides critical insights into combustion processes, fuel composition, and the efficacy of emission control technologies. Analyzing these minute particles, often invisible to the naked eye, allows for a detailed assessment of their composition, size distribution, and potential environmental and health impacts. This diagnostic approach facilitates informed decisions regarding fuel selection, combustion optimization, and the implementation of appropriate pollution mitigation strategies.

- Compositional Analysis

Determining the chemical constituents of particulate matter reveals the origin of emissions and the types of pollutants released. Techniques such as mass spectrometry and X-ray diffraction identify inorganic elements (e.g., heavy metals) and organic compounds (e.g., polycyclic aromatic hydrocarbons). Knowledge of the particulate composition informs source apportionment studies and helps pinpoint potential health hazards. For instance, the presence of high levels of sulfur-containing particles indicates the combustion of sulfur-rich fuels, prompting the evaluation of desulfurization technologies.

- Size Distribution Measurement

The size of particulate matter is a key determinant of its health effects and atmospheric behavior. Smaller particles (PM2.5 and PM10) can penetrate deeper into the respiratory system, increasing the risk of respiratory and cardiovascular diseases. Real-time monitoring using laser diffraction or cascade impactors provides data on the size distribution of particles in emissions. Facilities using advanced filtration systems can assess efficiency by monitoring PM2.5 levels. A shift towards smaller particle sizes may indicate incomplete combustion or filter degradation.

- Morphological Examination

Microscopic analysis, including scanning electron microscopy (SEM), reveals the shape and structure of individual particles. Morphological characteristics can provide clues about their formation mechanisms and sources. Soot particles, for example, exhibit a characteristic chain-like structure, while ash particles may display crystalline or amorphous forms. Identifying the morphology can help differentiate between combustion-related and non-combustion-related sources of particulate matter, facilitating the design of targeted control strategies.

- Source Apportionment Studies

By combining compositional, size, and morphological data, source apportionment studies can identify the relative contributions of different sources to particulate matter emissions. Statistical techniques, such as receptor modeling, link ambient particulate matter concentrations to specific sources, enabling policymakers to develop effective emission reduction strategies. These studies enable communities to prioritize emission control efforts and address the most significant contributors to air pollution. Examples include tracing high particulate matter concentrations in urban areas to industrial emissions or residential heating.

Comprehensive particulate matter analysis from vertical discharge sites serves as a vital tool for monitoring compliance with environmental regulations, assessing the performance of emission control technologies, and protecting public health. The insights gained from these analyses enable stakeholders to make informed decisions about fuel selection, combustion optimization, and the implementation of targeted pollution mitigation measures. The link between source emissions and ambient air quality underscores the need for detailed particulate characterization as a cornerstone of environmental management.

7. Environmental regulation adherence

Emissions from vertical structures, including smoke, are subject to stringent environmental regulations designed to protect air quality and public health. Non-compliance can result in significant penalties, including fines, operational restrictions, and legal action. These regulations dictate permissible levels of pollutants, such as particulate matter, sulfur dioxide, nitrogen oxides, and carbon monoxide, reflecting the direct correlation between emissions and regulatory oversight. Regulatory bodies, at local, regional, and national levels, enforce these standards through monitoring, permitting, and inspection programs. Failure to meet established emission limits triggers enforcement measures to rectify non-compliance and prevent further environmental damage. The impetus of environmental regulation, therefore, significantly shapes operational practices regarding the discharge of combustion byproducts.

Adhering to environmental regulations necessitates the implementation of emission control technologies, optimized combustion processes, and diligent monitoring programs. Industries invest in scrubbers, electrostatic precipitators, catalytic converters, and other control devices to reduce pollutant emissions. Proper maintenance and operation of these systems are essential for continuous compliance. Monitoring programs track emission levels and provide data for reporting to regulatory agencies. Continuous Emission Monitoring Systems (CEMS) are often required for large industrial sources to ensure real-time monitoring and compliance. Regulatory frameworks promote the adoption of cleaner fuels and energy-efficient technologies, encouraging the transition to more sustainable operational practices. For instance, power plants switching from coal to natural gas demonstrate a proactive approach to adhering to emission standards.

Compliance with environmental regulations governing vertical discharge emissions constitutes a critical element of responsible environmental stewardship. The interplay between regulatory frameworks and emission sources drives the development and implementation of technologies and practices aimed at minimizing air pollution and safeguarding public health. Challenges remain in ensuring consistent enforcement and adapting regulations to address emerging pollutants and evolving scientific understanding. However, the ongoing commitment to environmental regulation adherence remains paramount in mitigating the environmental impacts. This commitment enables a proactive approach to reducing vertical discharge emission impacts, promoting a balance between industrial activities and environmental sustainability.

Frequently Asked Questions

The following section addresses common inquiries regarding the visible emission from vertical structures, particularly concerning the implications of combustion byproduct release.

Question 1: What constitutes “smoke” emanating from a vertical discharge point?

The visible emission is a complex mixture of particulate matter, gaseous pollutants, and water vapor. The specific composition depends on the fuel source, combustion efficiency, and the presence of emission control systems. The color, density, and odor of the effluent provide indicators of the nature and extent of the pollution.

Question 2: Why is the emission from a vertical discharge point considered an environmental concern?

The effluent contains pollutants that contribute to air pollution, acid rain, and respiratory problems. Particulate matter, especially fine particles (PM2.5), poses a significant health risk due to its ability to penetrate deep into the lungs. Gaseous pollutants, such as sulfur dioxide and nitrogen oxides, can damage ecosystems and contribute to smog formation. The unregulated release constitutes an environmental hazard.

Question 3: How does the height of a vertical structure impact the dispersion of emissions?

A taller vertical structure facilitates greater plume rise, allowing the emission to mix with ambient air at higher altitudes. This results in lower ground-level concentrations of pollutants. Shorter structures concentrate emissions closer to the ground, potentially exacerbating localized air pollution problems. The design of a discharge system must account for height as a critical factor in managing dispersion.

Question 4: What technologies exist to mitigate the pollutants contained within a vertical emission?

Various emission control technologies are available, including scrubbers, electrostatic precipitators, and catalytic converters. Scrubbers remove gaseous pollutants through chemical reactions, while electrostatic precipitators capture particulate matter using electrical charges. Catalytic converters convert harmful gases into less toxic substances. The selection depends on the specific pollutants and emission characteristics.

Question 5: How does fuel choice influence the composition of a vertical emission?

The type of fuel combusted dictates the composition of emissions. Coal, especially coal with high sulfur content, releases significant amounts of sulfur dioxide. Natural gas produces fewer sulfur dioxide emissions but can still generate nitrogen oxides. Wood combustion results in particulate matter emissions. The choice of fuel is a crucial determinant of the environmental impact.

Question 6: What are the legal ramifications for exceeding permissible emission levels?

Exceeding permissible emission levels as defined by environmental regulations can result in significant penalties, including fines, operational restrictions, and legal action. Regulatory bodies enforce these standards through monitoring, permitting, and inspection programs. Compliance is essential to avoid legal repercussions and maintain responsible environmental practices.

In summary, understanding the components, impacts, and mitigation strategies associated with emissions from vertical structures is crucial for environmental stewardship and regulatory compliance.

The subsequent sections will delve into case studies illustrating successful emission reduction initiatives.

Conclusion

The preceding exploration of smoke from chimney has underscored the multifaceted nature of this phenomenon. Discussions have addressed its composition, environmental implications, and the regulatory frameworks governing its release. Effective mitigation strategies, including fuel optimization and the deployment of advanced control technologies, were presented as vital components of responsible environmental management.

Continued diligence in monitoring emissions, adhering to evolving regulations, and investing in cleaner combustion technologies remains paramount. The pursuit of sustainable practices within industries and communities reliant on combustion processes is essential to safeguard air quality and mitigate potential public health risks. Future progress necessitates a commitment to innovation, collaboration, and a proactive approach to minimizing the environmental footprint of combustion-related activities.