A vertical structure containing a flue or flues through which smoke and gases from a fire or furnace are carried up and away, generally above the roofline of a building. These structures are commonly constructed of brick, stone, or metal. An example is the tall brick structure atop a house that vents the exhaust from a fireplace.

The purpose is to provide effective ventilation, drawing combustion byproducts safely from the interior to the exterior atmosphere, preventing harmful substances from accumulating within the living space. Historically, these structures have been essential for heating homes and buildings with wood or coal fires, contributing significantly to indoor air quality and reducing the risk of carbon monoxide poisoning. They also play a crucial role in the overall structural integrity and architectural design of buildings.

Understanding the different types, construction methods, and maintenance requirements is essential for ensuring safe and efficient operation. Subsequent sections will delve into these aspects, providing a comprehensive overview of the components, inspection procedures, and repair techniques applicable to these vital building features.

Guidance Regarding Vented Stacks

Proper function and maintenance are paramount for safety and efficiency. Adherence to established protocols can prevent hazards and ensure optimal performance.

Tip 1: Regular Inspection: Conduct routine examinations to identify potential issues such as cracks, deterioration of materials, or obstructions. Early detection allows for timely repairs, preventing more extensive damage.

Tip 2: Professional Cleaning: Schedule professional sweeps at least annually, or more frequently if heavy use is typical. Removing creosote buildup mitigates the risk of chimney fires.

Tip 3: Damper Maintenance: Ensure the damper operates smoothly and seals tightly when closed. A malfunctioning damper can lead to energy loss and increased drafts.

Tip 4: Cap Installation: Install a cap to prevent rain, snow, debris, and animals from entering. This protects the flue from water damage and blockages.

Tip 5: Proper Fuel Selection: Use only seasoned, dry wood if operating a wood-burning appliance. Burning wet or unseasoned wood produces excessive smoke and creosote.

Tip 6: Address Water Leaks Promptly: Investigate and repair any water leaks immediately. Water penetration can cause significant structural damage and promote deterioration.

Tip 7: Monitor for Spalling: Observe the exterior for signs of spalling, where brick or stone surfaces flake and crumble. Spalling indicates water damage and requires professional attention.

Following these guidelines contributes to a safer and more efficient heating system, minimizing risks and maximizing operational lifespan.

The subsequent section will address advanced diagnostic techniques and specialized repair procedures for complex structural issues.

1. Ventilation for Combustion Gases

The essential function of a vertical exhaust system lies in providing effective ventilation for combustion gases. This critical process directly relates to its primary role in safely expelling harmful byproducts from heating appliances, such as fireplaces and furnaces, thereby protecting occupants and maintaining indoor air quality.

- Expulsion of Toxic Gases

The fundamental purpose is to remove hazardous gases like carbon monoxide, nitrogen dioxide, and sulfur dioxide produced during combustion. Without proper ventilation, these gases accumulate indoors, posing serious health risks, including carbon monoxide poisoning and respiratory irritation. The dimensions and design of the flue are crucial in ensuring efficient and complete removal of these gases.

- Creation of Draft

The design promotes an upward draft, drawing combustion gases away from the appliance and into the flue. This natural draft is influenced by factors such as flue height, internal diameter, and temperature difference between the flue gases and the outside air. An adequate draft ensures consistent and efficient operation of the heating appliance.

- Prevention of Backdrafting

Proper ventilation minimizes the risk of backdrafting, a dangerous phenomenon where combustion gases are drawn back into the living space. Backdrafting can occur due to negative pressure within the building, caused by exhaust fans or tightly sealed construction. Correctly sized and maintained structures are designed to prevent this reversal of airflow, safeguarding occupants from exposure to harmful gases.

- Facilitation of Efficient Combustion

By providing adequate airflow, the system contributes to more complete and efficient combustion within the appliance. This not only reduces the production of pollutants but also improves the overall efficiency of the heating process, minimizing fuel consumption and maximizing heat output. The design must accommodate the specific requirements of the heating appliance to ensure optimal performance.

The intricate relationship between ventilation for combustion gases and the overall structure is vital for its safe and effective function. These elements, acting in concert, ensure that combustion byproducts are efficiently and safely removed from the building, contributing to a healthier and more comfortable indoor environment. Ignoring any aspect of these factors can lead to dangerous consequences.

2. Structural Component of Buildings

The integration as a structural component within buildings extends beyond its function as a mere exhaust conduit. Its design and construction directly impact the stability, integrity, and longevity of the building itself. The structural implications of its presence require careful consideration during building design and maintenance.

- Load Bearing Considerations

In many older buildings, the structure can contribute to the overall load-bearing capacity of walls. The mass and construction materials (brick, stone) can provide significant vertical support. Consequently, alterations or removal must be carefully engineered to avoid compromising the building’s structural stability. Modern examples might utilize steel reinforcements within the structure to handle increased loads.

- Lateral Stability and Wind Resistance

The structure’s height and exposure make it vulnerable to wind forces. It must be designed to withstand these lateral loads and transfer them safely to the building’s foundation. Proper bracing and anchoring are essential to prevent collapse during high winds. Failure to account for wind loads can lead to cracking, displacement, or even complete structural failure of the structure and adjacent building components.

- Integration with Roofing Systems

The point where the structure intersects the roof presents a critical area for weatherproofing and structural integration. Improper flashing or sealing can lead to water leaks, which can damage the roof structure and the structure itself, leading to deterioration of the brickwork or mortar. The design must ensure a watertight seal and accommodate differential movement between the and the roof due to thermal expansion and contraction.

- Impact on Building Aesthetics

Beyond its structural function, the element significantly influences the building’s aesthetic appearance. Its design, materials, and placement contribute to the overall architectural style and character. The design can be seamlessly integrated into the building’s design, or deliberately made a focal point. Considerations of aesthetics must not compromise structural integrity or functionality.

These structural considerations demonstrate that the vertical conduit is far more than a simple flue. It functions as an integral part of the building’s structural system, affecting its stability, weather resistance, and aesthetic appeal. Understanding these connections is crucial for ensuring the long-term safety and performance of both the structure and the building it serves. Modern construction often employs engineered solutions to optimize these structural relationships.

3. Material Composition and Construction

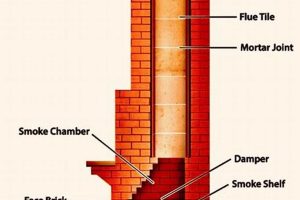

The efficacy and longevity are directly correlated with the materials used in its construction. The choice of materials dictates its ability to withstand high temperatures, corrosive flue gases, and external weather conditions. Traditional construction utilized materials such as brick, stone, and clay tiles, valued for their thermal resistance and durability. Modern construction incorporates materials like stainless steel and pre-fabricated metal components, offering improved resistance to corrosion and ease of installation. Improper material selection leads to premature deterioration, compromising structural integrity and posing safety hazards. For example, using unlined brick flues with high-efficiency gas appliances can cause rapid deterioration due to acidic condensate.

Construction methods are equally important. Proper mortar joints in brick or stone structures prevent water penetration and maintain structural stability. Correct flue liner installation ensures efficient gas venting and protects the surrounding structure from heat damage. The absence of a proper rain cap leads to water infiltration, accelerating deterioration of the flue liner and masonry. Furthermore, the foundation must be adequately sized and constructed to support the weight, preventing settling and cracking. An incorrectly constructed foundation can lead to structural instability, potentially requiring costly repairs or even complete reconstruction.

In summary, careful material selection and adherence to proper construction techniques are paramount for ensuring a safe and durable structure. The inherent connection between these elements dictates its ability to function effectively and withstand environmental stresses. Neglecting either aspect results in compromised performance and potential safety risks, highlighting the importance of skilled craftsmanship and informed decision-making in construction and maintenance. This understanding is critical for both homeowners and building professionals to ensure long-term safety and efficiency.

4. Draft Control and Efficiency

Effective draft control is integral to the operational efficiency of a ventilation stack. The proper regulation of airflow ensures optimal combustion, minimizes heat loss, and prevents the backflow of combustion gases. Precise management of airflow within the structure directly impacts both performance and safety.

- Flue Size and Design

The dimensions of the flue directly affect the draft. An undersized flue restricts airflow, leading to incomplete combustion and potential backdrafting. An oversized flue, conversely, can result in excessive heat loss and reduced draft. The design must be carefully matched to the heating appliance to ensure optimal performance. For instance, a wood-burning stove requires a different flue size than a gas furnace.

- Damper Systems

Dampers regulate airflow by controlling the opening within the flue. A properly functioning damper minimizes heat loss when the appliance is not in use. However, a malfunctioning damper can restrict airflow during operation, leading to incomplete combustion and the accumulation of dangerous gases. Regular inspection and maintenance of the damper are essential for maintaining efficiency and safety.

- Stack Height and Location

The height significantly influences draft strength. Taller structures generally produce a stronger draft due to the greater temperature differential between the flue gases and the outside air. The location relative to surrounding structures and wind patterns can also affect draft performance. A tall building near the can create downdrafts, hindering its proper function. Proper siting and height adjustments may be necessary to overcome these external influences.

- Barometric Draft Regulators

These devices automatically adjust the draft to maintain a consistent level, regardless of external weather conditions. By introducing ambient air into the flue, they stabilize the draft and prevent excessive airflow, improving combustion efficiency and reducing fuel consumption. These regulators are particularly beneficial for appliances sensitive to draft fluctuations.

These interrelated elements of draft control and efficiency are essential for the safe and effective operation. Optimizing these factors leads to improved heating performance, reduced fuel consumption, and enhanced safety. Neglecting these aspects results in compromised efficiency, potential hazards, and increased operating costs.

5. Safety Against Fire Hazards

The correlation between a structure designed to vent smoke and combustion gases and safeguarding against fire hazards is undeniable and fundamental. Proper design, maintenance, and usage protocols are crucial in mitigating fire risks associated with these essential building components.

- Creosote Accumulation and Mitigation

Creosote, a byproduct of incomplete combustion in wood-burning appliances, accumulates within the flue. This highly flammable substance poses a significant fire hazard. Regular sweeping by qualified professionals removes creosote deposits, reducing the risk of chimney fires. Neglecting this maintenance can lead to rapid creosote buildup, potentially resulting in a dangerous and destructive fire within the chimney structure.

- Flue Liner Integrity and Protection

The flue liner, typically made of clay, metal, or concrete, protects the surrounding combustible materials of the building from the intense heat generated by combustion. Cracks or deterioration in the liner compromise this protection, increasing the risk of fire spreading to adjacent walls or roofing. Regular inspections and timely repairs are essential to maintain the liner’s integrity and prevent fire hazards. Failure to maintain the flue liner can lead to catastrophic structural fires.

- Spark Arrestors and Debris Prevention

A spark arrestor, often a mesh screen installed at the top of a structure, prevents embers and sparks from escaping and potentially igniting nearby vegetation or roofing materials. Furthermore, it prevents debris such as leaves, branches, and animal nests from entering and obstructing the flue. Blockages restrict airflow, increasing the risk of backdrafting and carbon monoxide poisoning. Maintaining a functioning spark arrestor is vital for preventing both fire hazards and ventilation problems.

- Proper Appliance Installation and Usage

Correct installation of heating appliances, such as wood stoves and fireplaces, is critical for ensuring safe operation. Adhering to manufacturer’s instructions and local building codes minimizes the risk of overheating and fire. Furthermore, using appropriate fuel and following safe burning practices, such as avoiding overfilling the firebox, reduces the production of creosote and minimizes the risk of chimney fires. Improper appliance installation and usage significantly elevate the risk of fire hazards.

The aforementioned facets highlight the critical connection between the structure and fire safety. Addressing each of these elements through regular inspection, maintenance, and responsible usage is essential for minimizing the risk of fire and ensuring the safe and efficient operation of heating appliances. Neglecting any of these aspects increases the potential for devastating consequences.

6. Maintenance and Inspection Protocols

The long-term functionality and safety of a vertical exhaust system are intrinsically linked to rigorous maintenance and inspection protocols. As a critical building component responsible for expelling combustion byproducts, its degradation can lead to significant hazards, including carbon monoxide poisoning and structural fires. Regular inspections, conducted by qualified professionals, are essential for identifying potential issues such as creosote buildup, flue liner damage, and structural deterioration. For instance, a cracked flue liner, if left unaddressed, can allow heat and combustion gases to escape, potentially igniting nearby combustible materials. Scheduled maintenance, including chimney sweeping and repairs to damaged components, mitigates these risks and ensures efficient operation. The absence of consistent maintenance transforms a vital safety feature into a potential liability.

The practical application of stringent protocols extends to both residential and commercial settings. In residential homes, annual inspections are recommended, particularly for those utilizing wood-burning appliances. These inspections typically involve a visual examination of the structure, the flue liner, and the damper, followed by a sweep to remove accumulated creosote. In commercial environments, where heating systems often operate more frequently and at higher capacities, more frequent inspections and specialized maintenance procedures may be necessary. This is particularly important for industrial facilities that utilize chimneys to vent corrosive gases, requiring corrosion-resistant materials and specialized inspection techniques to detect early signs of degradation. Regardless of the setting, documented inspection reports provide a valuable record of the system’s condition, facilitating informed decision-making regarding repairs and upgrades.

In conclusion, the connection between maintenance and inspection protocols and the operational effectiveness is not merely procedural but fundamental. The application of these protocols serves as a proactive measure, transforming what is otherwise a static building component into a system subject to continuous monitoring and improvement. Challenges persist in ensuring widespread adherence to these protocols, particularly in older buildings where original construction standards may be outdated. Addressing these challenges requires ongoing education and the enforcement of building codes, underscoring the importance of a proactive approach to chimney safety.

Frequently Asked Questions About Vertical Exhaust Vents

The following addresses common inquiries regarding the function, maintenance, and safety aspects of these structures. The answers aim to provide clarity and promote informed decision-making concerning this critical building component.

Question 1: What is the primary purpose?

The primary purpose is to safely vent combustion byproducts from heating appliances, such as fireplaces and furnaces, to the outside atmosphere. This prevents the accumulation of harmful gases within the building.

Question 2: How often should a venting stack be inspected?

A venting stack should be inspected at least annually by a qualified professional. More frequent inspections may be necessary for systems that are used heavily or that burn solid fuels.

Question 3: What are the signs of a failing or damaged structure?

Signs of a failing or damaged structure include cracks in the masonry, spalling brickwork, loose or missing mortar, water leaks, and the presence of creosote buildup. Any of these signs warrant immediate attention.

Question 4: What is creosote, and why is it dangerous?

Creosote is a highly flammable byproduct of incomplete combustion that accumulates within the flue. It is dangerous because it poses a significant fire hazard. Regular sweeping removes creosote buildup, reducing the risk of structure fires.

Question 5: Can the structure be removed without affecting the building’s structural integrity?

The structure can sometimes be removed, but it requires careful assessment by a structural engineer. In some older buildings, the structure may contribute to the building’s overall stability. Removal must be engineered to avoid compromising the building’s structural integrity.

Question 6: What are the typical materials used in construction?

Typical materials used in construction include brick, stone, concrete, clay tiles, and metal (such as stainless steel). The choice of materials depends on the type of heating appliance, the climate, and local building codes.

Understanding these fundamental questions provides a foundation for maintaining the safety and efficiency of these systems. Continued vigilance and professional expertise are essential for ensuring their long-term performance.

The next article section will address the role of building codes and regulations in ensuring the safety and performance of these vital building features.

Conclusion

This exploration of what is a chimney has elucidated its multifaceted role, extending beyond a simple exhaust conduit. Its function is inextricably linked to both building safety and structural integrity, encompassing ventilation, fire prevention, and architectural considerations. Diligent maintenance, regular inspection, and adherence to established safety protocols are paramount for ensuring continued performance and mitigating potential hazards.

The enduring presence underscores its historical significance and ongoing relevance in contemporary construction. A commitment to understanding its complexities and upholding rigorous safety standards remains crucial for safeguarding lives and preserving the structural integrity of buildings for generations to come. Prioritizing education and responsible practices regarding these fundamental building features is a shared responsibility.