A device designed to prevent air leakage and moisture intrusion through an unused or compromised flue is a crucial component in maintaining home energy efficiency. These barriers, typically constructed from inflatable materials or rigid panels, are installed within the chimney to create an airtight closure. As an example, consider a homeowner with a fireplace that is no longer in use; without a proper barrier, the chimney acts as a conduit for heat loss during winter and allows warm, humid air to enter during summer.

Effectively isolating the chimney opening provides numerous advantages. This includes a demonstrable reduction in heating and cooling costs by preventing conditioned air from escaping and external air from entering. Furthermore, these installations protect the home from potential water damage caused by rain and snow entering the flue, which can lead to deterioration of the chimney structure and surrounding building materials. Historically, less sophisticated methods were employed, but modern solutions offer superior performance and ease of installation.

The following discussion will delve into the various types available, proper installation techniques, and considerations for selecting the most suitable solution for specific chimney configurations. Understanding these aspects will enable homeowners and building professionals to make informed decisions regarding their implementation for optimal performance and longevity.

Chimney Closure Best Practices

The effective utilization of flue closures requires careful consideration to ensure optimal performance and longevity. Adherence to the following guidelines will maximize energy savings and protect against potential structural damage.

Tip 1: Select the Appropriate Type: The choice of closure device depends on the specific dimensions and condition of the chimney flue. Inflatable models are suitable for irregular shapes and sizes, while rigid panels provide a more durable solution for standard flues. Assess the flue’s interior dimensions and any existing damage before making a selection.

Tip 2: Ensure Proper Sizing: A properly sized device is crucial for creating an airtight seal. Measure the flue opening precisely, accounting for any irregularities. An undersized closure will fail to prevent air leakage, while an oversized one may be difficult to install and could damage the flue.

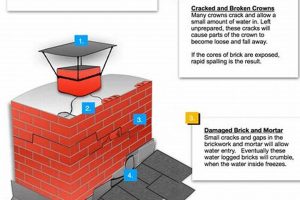

Tip 3: Inspect for Existing Damage: Prior to installation, thoroughly inspect the chimney flue for cracks, loose bricks, or other signs of deterioration. Address any existing damage before installing the closure to prevent further degradation and ensure a secure fit.

Tip 4: Follow Installation Instructions Carefully: Adhere strictly to the manufacturer’s installation instructions. Incorrect installation can compromise the seal’s effectiveness and may lead to safety hazards. Use appropriate tools and techniques as recommended by the manufacturer.

Tip 5: Verify Seal Integrity: After installation, carefully inspect the perimeter of the device to ensure a complete and airtight seal. Use a smoke pencil or incense stick to detect any air leaks. Address any leaks promptly by adjusting the device or applying additional sealant.

Tip 6: Consider Material Compatibility: When using sealants or adhesives, ensure compatibility with the chimney’s construction materials and the closure device. Incompatible materials can degrade over time, compromising the seal’s integrity.

Effective chimney closure strategies contribute significantly to home energy efficiency and prevent potential structural damage. Implementing these guidelines ensures optimal performance and long-term cost savings.

The subsequent sections will explore the maintenance requirements and long-term benefits associated with correctly installed flue closures.

1. Material Durability

Material durability constitutes a critical factor in the long-term effectiveness of chimney flue closures. The chimney environment presents a harsh combination of temperature fluctuations, moisture exposure, and potential chemical attack from combustion byproducts. Consequently, the materials used in the construction of these devices must exhibit a high degree of resistance to degradation to maintain an effective seal over an extended period. For example, an inflatable closure constructed from a low-grade polymer may rapidly deteriorate under exposure to high temperatures, leading to air leakage and a compromised seal. Conversely, a closure fabricated from a reinforced, heat-resistant polymer or a rigid metal panel demonstrates superior longevity and sustained performance.

The selection of appropriate materials directly impacts the lifecycle cost and overall performance of the closure. Premature failure due to material degradation necessitates replacement, incurring additional expense and potentially exposing the chimney to moisture damage in the interim. Consider a coastal environment where chimney structures are exposed to high levels of salt spray; a metal closure lacking adequate corrosion protection will rapidly degrade, negating its initial cost advantage compared to a more durable, corrosion-resistant alternative. Therefore, a comprehensive assessment of environmental conditions and material properties is essential for informed decision-making.

In summary, material durability is not merely a desirable attribute but a fundamental requirement for effective and reliable chimney flue closures. Prioritizing durable materials translates to reduced maintenance, extended service life, and sustained energy savings. A thorough understanding of material properties and their interaction with the chimney environment is essential for selecting a solution that provides long-term protection and economic value.

2. Proper Installation

Correct fitting of a chimney flue closure is paramount to its intended function. Deviations from recommended procedures can compromise the seal’s integrity, negating potential energy savings and potentially leading to structural damage. The following outlines key facets of appropriate installation.

- Flue Measurement Accuracy

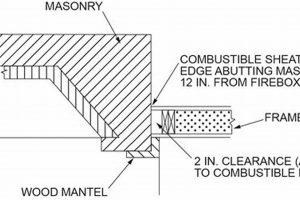

Precise measurement of the chimney flue opening constitutes the initial step. Discrepancies between the measured dimensions and the closure device can result in an inadequate fit. For instance, an undersized closure will fail to completely seal the opening, allowing air infiltration. An oversized closure, conversely, may exert undue pressure on the flue walls, potentially causing cracking or other structural damage. Therefore, accurate measurement, utilizing appropriate tools and techniques, is essential.

- Surface Preparation

The condition of the flue surface directly impacts the closure’s ability to form an airtight seal. Debris, soot, or crumbling mortar can create an uneven surface, preventing complete contact between the closure and the flue wall. Thorough cleaning and repair of any surface imperfections are necessary before installation. Failure to prepare the surface adequately will compromise the seal’s effectiveness and potentially shorten the closure’s lifespan.

- Adherence to Manufacturer Instructions

Each type of closure device possesses unique installation requirements. Strict adherence to the manufacturer’s instructions is crucial for ensuring proper function and longevity. Ignoring these instructions can lead to incorrect assembly, improper sealing, or damage to the closure itself. For example, an inflatable closure may require specific inflation pressures; exceeding these pressures can cause rupture, while insufficient pressure will result in an inadequate seal.

- Post-Installation Verification

Following installation, a thorough inspection of the seal’s integrity is necessary. This may involve visual inspection for gaps or the use of a smoke test to detect air leaks. Any identified leaks must be addressed promptly to ensure the closure’s effectiveness. Failure to verify the seal can result in continued energy loss and potential moisture intrusion.

These interconnected elements underscore the importance of precise and deliberate installation practices when implementing chimney flue closures. A meticulous approach guarantees optimal performance, safeguarding the chimney structure and maximizing energy efficiency.

3. Effective Sealing

Effective sealing constitutes a critical performance parameter for chimney flue closures. The primary objective of these installations is to prevent uncontrolled air exchange between the interior of the building and the external environment. The integrity of this barrier directly influences energy consumption, moisture control, and overall structural preservation.

- Material Compatibility and Adhesion

The selection of compatible sealing materials is essential for achieving a durable and airtight barrier. The sealant must exhibit strong adhesion to both the chimney flue material and the closure device itself. Incompatible materials can lead to bond failure, creating pathways for air and moisture infiltration. For example, silicone sealants demonstrate good flexibility and water resistance but may not adhere effectively to certain types of masonry, necessitating the use of specialized adhesives.

- Airtight Closure Design

The design of the closure device itself significantly impacts the effectiveness of the seal. Closures with interlocking edges or compression seals provide a more robust barrier against air leakage than simple, flat closures. The design should account for potential irregularities in the flue surface, ensuring consistent contact and compression to maintain an airtight seal. A poorly designed closure may exhibit gaps or weak points, compromising its effectiveness.

- Environmental Resistance

The sealing material must withstand the harsh environmental conditions present within a chimney flue. This includes resistance to temperature fluctuations, exposure to moisture, and potential chemical attack from combustion byproducts. Sealants that degrade under these conditions will lose their effectiveness over time, requiring replacement and potentially leading to structural damage. Selecting sealants specifically formulated for chimney applications is crucial for ensuring long-term performance.

- Proper Application Technique

Even with compatible materials and a well-designed closure, proper application technique is essential for achieving an effective seal. This includes thorough cleaning of the flue surface, precise application of the sealant, and appropriate compression of the closure device. Failure to follow proper application procedures can result in air pockets, incomplete coverage, and reduced sealing effectiveness. Professional installation often ensures adherence to best practices and optimal performance.

These interconnected facets emphasize the multifaceted nature of effective sealing in chimney flue closures. A comprehensive approach, encompassing material selection, design considerations, environmental resistance, and application technique, is necessary to achieve a durable and airtight barrier. This, in turn, maximizes energy efficiency, prevents moisture intrusion, and contributes to the long-term preservation of the chimney structure.

4. Flue Dimensions

Flue dimensions represent a foundational consideration in the effective application of chimney flue closures. The internal measurements of the flue, including its diameter or cross-sectional area, directly dictate the suitability and performance of any installed closure device. An improperly sized closure, relative to the flue dimensions, invariably compromises its ability to form an airtight seal. For instance, if the chimneys opening measures 12 inches in diameter, a closure designed for a 10-inch flue will inherently fail to provide the necessary barrier against air infiltration.

The correlation between flue dimensions and closure effectiveness extends beyond simple size compatibility. Irregularities in the flue’s shape, such as warping or ovality, necessitate careful measurement and closure selection. An inflatable closure, for example, can conform to minor irregularities, whereas a rigid panel might require custom fitting or be entirely unsuitable. Furthermore, neglecting to account for these dimensional nuances can lead to improper installation, potentially damaging the flue itself. Consider an older chimney where years of weathering have caused the flue to become significantly distorted; attempting to force a rigid closure into such a flue risks cracking the masonry and exacerbating the problem.

In summary, accurate assessment of flue dimensions is paramount when selecting and installing chimney closures. This assessment ensures optimal sealing performance, prevents potential damage to the chimney structure, and contributes to the overall energy efficiency of the building. Failure to consider this critical factor can undermine the intended benefits of the closure, leading to wasted resources and potential structural issues.

5. Moisture Prevention

The effective management of moisture intrusion represents a primary concern in chimney maintenance and structural preservation. Flue closures, when properly implemented, contribute significantly to mitigating water-related damage within the chimney system and the surrounding building elements. Uncontrolled moisture ingress can lead to a cascade of detrimental effects, ranging from accelerated material degradation to compromised indoor air quality.

- Reduced Interior Deterioration

A key role of flue closures lies in preventing rainwater and snowmelt from directly entering the chimney flue. This, in turn, minimizes the saturation of brickwork, mortar joints, and internal flue liners. Prolonged exposure to moisture accelerates freeze-thaw cycles, leading to cracking and spalling of masonry materials. Consider an unsealed chimney exposed to winter conditions; repeated freezing and thawing can cause significant structural damage over time, necessitating costly repairs.

- Inhibition of Mold Growth

Damp chimney environments provide ideal conditions for mold and mildew proliferation. These organisms not only degrade building materials but also release spores into the indoor environment, potentially impacting occupant health. By preventing moisture ingress, flue closures inhibit mold growth and contribute to improved indoor air quality. A properly sealed chimney prevents the introduction of moisture necessary for mold colonies to establish and thrive.

- Protection of Fireplace Components

Moisture intrusion can damage critical fireplace components, such as the damper and firebox. Rust and corrosion can compromise the functionality of the damper, reducing its ability to effectively control airflow. Similarly, moisture can weaken the firebox lining, potentially leading to cracking and eventual failure. Flue closures protect these components by minimizing their exposure to water and humidity, extending their lifespan and ensuring safe operation.

- Prevention of Water Stains and Leaks

Uncontrolled water ingress through the chimney can manifest as unsightly stains on interior walls and ceilings. In severe cases, it can lead to active leaks, causing significant damage to building finishes and structural elements. Flue closures effectively prevent these issues by providing a barrier against moisture penetration. A well-sealed chimney ensures that water is diverted away from the building envelope, preserving the integrity of interior spaces.

These multifaceted benefits underscore the critical role of flue closures in preventing moisture-related damage within chimney systems. By effectively managing water intrusion, these devices contribute to the long-term preservation of the chimney structure, improved indoor air quality, and reduced maintenance costs. In essence, flue closures serve as a proactive measure to safeguard the building against the detrimental effects of uncontrolled moisture.

6. Energy Conservation

Energy conservation, in the context of residential and commercial structures, is inextricably linked to the management of heat transfer through building envelopes. Chimneys, as vertical shafts designed for combustion exhaust, can also serve as significant conduits for energy loss if not properly managed. Consequently, the effective utilization of chimney flue closures represents a critical component in optimizing building energy performance.

- Reduced Heating and Cooling Load

An open or poorly sealed flue facilitates the escape of heated air during winter and the influx of warm air during summer, placing a greater burden on heating and cooling systems. Installing a flue closure effectively minimizes this uncontrolled air exchange, reducing the energy required to maintain a comfortable indoor temperature. Consider a home with an unused fireplace; without a flue closure, the chimney acts as a vent, continuously drawing conditioned air out of the living space.

- Minimized Air Leakage

Unsealed flues contribute to overall building air leakage, a primary driver of energy inefficiency. Air infiltration through the chimney can account for a substantial percentage of total air leakage in older homes, particularly those with poorly insulated walls and windows. A well-fitted flue closure significantly reduces this leakage, improving the building’s overall airtightness and reducing energy consumption. Studies have shown that sealing unused flues can result in a measurable decrease in heating and cooling costs.

- Prevention of Convection Losses

The chimney effect, driven by temperature differentials between the interior and exterior of the building, creates a natural convective current through the flue. This convection draws warm air upwards and out of the building, even when the fireplace is not in use. A flue closure effectively disrupts this convective current, preventing the continuous loss of heated air. This is especially relevant in taller buildings where the chimney effect is more pronounced.

- Optimized HVAC System Efficiency

By reducing the heating and cooling load and minimizing air leakage, flue closures contribute to the improved efficiency of heating, ventilation, and air conditioning (HVAC) systems. With a reduced demand for heating and cooling, HVAC systems operate for shorter durations and at lower capacities, resulting in lower energy consumption and extended equipment lifespan. This optimization translates to tangible savings on utility bills and reduced environmental impact.

The various facets outlined above underscore the integral role of chimney flue closures in promoting energy conservation within buildings. By mitigating heat transfer, minimizing air leakage, and optimizing HVAC system efficiency, these devices contribute significantly to reducing energy consumption and enhancing overall building sustainability. Implementing effective chimney closure strategies represents a practical and cost-effective approach to achieving meaningful energy savings.

7. Structural Integrity

Structural integrity, representing the ability of a structure to withstand imposed loads without failure, is critically intertwined with the functionality of chimney flue closures. The condition of a chimney directly impacts the safety and longevity of the building it serves, and the proper application of these seals plays a vital role in preserving that condition. The subsequent discussion will delineate specific ways in which closures contribute to the structural soundness of chimney systems.

- Protection Against Water Damage

Uncontrolled water ingress is a primary driver of chimney degradation. Water intrusion accelerates freeze-thaw cycles, leading to cracking and spalling of masonry. Flue closures mitigate this damage by preventing direct exposure of the chimney’s interior to rain and snow. Consider a chimney without a closure in a region with harsh winters; the cumulative effect of repeated freezing and thawing weakens the structure over time, potentially leading to collapse. A closure diverts water, minimizing this risk.

- Prevention of Mortar Deterioration

Mortar joints are particularly vulnerable to moisture-related damage. Water infiltration weakens the mortar, leading to loss of adhesion and structural instability. Closures reduce the amount of water that penetrates the chimney, preserving the integrity of the mortar joints. Deteriorated mortar compromises the chimney’s ability to withstand wind loads and seismic activity, increasing the risk of structural failure. A sound flue closure helps maintain the mortar’s strength and stability.

- Mitigation of Chemical Attack

Combustion byproducts, particularly those from burning fossil fuels, can create acidic conditions within the chimney flue. These acids attack the masonry and mortar, accelerating their degradation. While not a complete solution, closures help minimize the entry of rainwater that can exacerbate this chemical attack by dissolving and transporting these corrosive substances. By reducing water intrusion, closures slow down the rate of chemical deterioration, extending the chimney’s lifespan.

- Stabilization of Flue Liner

The flue liner, whether constructed from clay tile, metal, or cast-in-place concrete, protects the chimney’s masonry from heat and corrosive combustion gases. Damage to the liner compromises the chimney’s structural integrity. Closures prevent water from entering and saturating the space between the liner and the masonry, minimizing freeze-thaw damage and preventing liner displacement. A stable flue liner ensures that the chimney can safely vent combustion gases without compromising its structural integrity.

The aforementioned aspects underscore the critical relationship between flue closures and the sustained structural integrity of chimney systems. While closures represent only one element of a comprehensive chimney maintenance program, their contribution to preventing water damage, preserving mortar integrity, mitigating chemical attack, and stabilizing the flue liner is undeniable. Proper implementation of these sealing devices represents a proactive measure in safeguarding the long-term structural health and safety of the building.

Frequently Asked Questions Regarding Chimney Closures

This section addresses common inquiries concerning chimney flue closures, providing factual and objective information to facilitate informed decision-making.

Question 1: What constitutes an appropriate application for a chimney seal?

A chimney seal is primarily indicated for flues that are not actively in use. This includes situations where a fireplace has been permanently decommissioned or when seasonal use dictates prolonged periods of inactivity. The objective is to prevent air leakage and moisture intrusion during these periods.

Question 2: How does a chimney seal contribute to energy efficiency?

By creating an airtight barrier within the flue, a chimney seal minimizes the exchange of air between the interior of the building and the external environment. This reduces heat loss during colder months and prevents the influx of warm air during warmer months, thereby lowering heating and cooling costs.

Question 3: What types of chimney seals are available?

Chimney seals are generally categorized into two primary types: inflatable and rigid. Inflatable seals conform to irregular flue shapes and are suitable for temporary applications. Rigid seals, typically constructed from metal or durable plastic, provide a more permanent solution for standard flue dimensions.

Question 4: How is the correct size of chimney seal determined?

Accurate measurement of the flue opening is essential for selecting the appropriate seal size. Measure the internal dimensions of the flue using a measuring tape or caliper. The chosen seal should slightly exceed these measurements to ensure a tight and effective seal.

Question 5: What potential risks are associated with improper installation of a chimney seal?

Incorrect installation can compromise the seal’s effectiveness, negating potential energy savings. Furthermore, an improperly sized or installed seal can exert undue pressure on the flue walls, potentially leading to cracking or structural damage.

Question 6: What is the expected lifespan of a chimney seal?

The lifespan of a chimney seal varies depending on the type of material, environmental conditions, and frequency of use. Rigid seals typically exhibit greater longevity compared to inflatable seals. Regular inspection and maintenance are recommended to ensure continued effectiveness.

In summary, chimney flue closures provide significant benefits in terms of energy efficiency and structural preservation when properly selected, installed, and maintained. It is crucial to adhere to recommended procedures and consider the specific characteristics of the chimney to ensure optimal performance.

The subsequent section will explore the environmental considerations associated with chimney operation and maintenance.

Chimney Seals

Throughout this discourse, the critical role of chimney seals in maintaining structural integrity, maximizing energy efficiency, and mitigating moisture-related damage has been comprehensively examined. The selection of appropriate materials, precise installation techniques, and consistent maintenance practices are paramount for ensuring optimal performance and longevity of these essential components. Furthermore, the long-term implications of neglecting proper flue management, including potential structural deterioration and increased energy consumption, have been clearly articulated.

Therefore, a diligent approach to chimney flue closure implementation is not merely an optional consideration but a responsible course of action. By prioritizing the correct application of chimney seals, building owners and managers can proactively safeguard their investments, promote sustainable energy practices, and ensure the continued safety and functionality of their structures. The long-term benefits associated with this preventative measure far outweigh the initial investment, making it an essential element of responsible building management.