Chimney terminations crafted from a reddish-brown metal, valued for its durability and aesthetic appeal, are often employed to crown residential and commercial structures. These structures, designed to vent combustion byproducts safely away from inhabited spaces, benefit from the material’s resistance to corrosion and its distinctive appearance. For instance, a building owner might select this type of termination to enhance the architectural character of their property while ensuring efficient and long-lasting chimney function.

The implementation of such metallic chimney extensions provides several advantages, including prolonged lifespan compared to more conventional materials like terracotta or concrete. Furthermore, the natural patina that develops over time contributes to a unique visual character, blending well with various architectural styles. Historically, the use of this particular metal signifies quality and refinement, often indicating a commitment to superior craftsmanship and long-term value.

The following sections will delve into the specific construction methods, installation procedures, and maintenance requirements associated with these sophisticated chimney components. Additionally, a detailed examination of the different styles, sizes, and design considerations will be provided to aid in informed decision-making regarding chimney termination selection.

Essential Considerations for Chimney Terminations Fabricated from Copper

The following guidelines offer crucial information for selecting, installing, and maintaining chimney terminations constructed using a specific metallic element, ensuring longevity and optimal performance.

Tip 1: Material Grade Verification: Prior to installation, confirm the copper alloy meets established industry standards for durability and corrosion resistance. Specify a minimum thickness to ensure structural integrity against environmental stressors such as wind and precipitation.

Tip 2: Professional Installation is Mandatory: Employ qualified and licensed chimney professionals for installation. Proper sealing and flashing techniques are critical to prevent water penetration and subsequent structural damage to the chimney and surrounding building materials.

Tip 3: Regular Inspection Protocol: Conduct annual inspections of the chimney termination, focusing on signs of corrosion, damage from debris, or compromised seals. Address any issues promptly to prevent escalation and costly repairs.

Tip 4: Lightning Protection Integration: Evaluate the potential need for lightning protection systems, especially in regions prone to electrical storms. A properly grounded lightning rod can mitigate the risk of catastrophic damage to the chimney and the structure it serves.

Tip 5: Compatible Cleaning Methods: Utilize cleaning methods and products specifically designed for copper. Abrasive cleaners can scratch the surface and accelerate the patination process unevenly. Consult with a chimney professional for recommended cleaning procedures.

Tip 6: Consider Architectural Compatibility: Select a style and design that complements the overall architectural aesthetic of the building. Variations in cap design, height, and ornamentation can significantly impact the visual appeal.

Tip 7: Address Potential Electrolytic Corrosion: Be mindful of potential electrolytic corrosion if the copper component comes into contact with dissimilar metals, such as steel or aluminum. Employ a dielectric barrier to prevent galvanic reactions.

Adhering to these guidelines ensures the long-term performance, safety, and aesthetic value of metallic chimney terminations, safeguarding the structural integrity of the chimney system and the building it serves.

The subsequent sections of this document will provide an in-depth analysis of maintenance procedures and potential troubleshooting scenarios related to these chimney components.

1. Durability

The selection of copper for chimney terminations is inextricably linked to the material’s inherent durability. This characteristic represents a pivotal factor in mitigating long-term maintenance costs and ensuring consistent chimney functionality. A primary cause-and-effect relationship exists: employing high-quality copper alloys translates directly into extended lifespan, reducing the frequency of repairs or replacements typically associated with less robust materials. For example, in regions exposed to harsh weather conditions, such as coastal areas with high salinity, terminations fabricated from copper demonstrate superior resistance to corrosion compared to alternative materials like steel or concrete, which are more susceptible to degradation.

The durability of copper chimney terminations is not merely a matter of longevity; it also impacts operational efficiency. A structurally sound chimney pot, resistant to cracking or deformation, maintains optimal draft, facilitating the efficient removal of combustion byproducts. Conversely, a compromised chimney pot can impede airflow, potentially leading to dangerous carbon monoxide buildup within the dwelling. Consider the historical use of copper in roofing and guttering; its proven track record in these applications underscores its suitability for demanding exterior environments, reinforcing the practical advantages of using it for chimney terminations. A case study involving heritage buildings across Europe with well-preserved copper chimney pots that have endured for centuries provides tangible evidence of copper’s resilience.

In summary, the durability afforded by copper is a critical element in the overall performance and value proposition of metallic chimney terminations. Understanding this connection informs better decision-making regarding material selection and maintenance strategies. While the initial investment may be higher compared to less durable materials, the reduced long-term maintenance costs and enhanced safety features associated with copper chimney terminations represent a compelling argument for their adoption. Ignoring the importance of durability can lead to premature failure of the chimney system and potentially jeopardize the safety and well-being of the occupants.

2. Corrosion Resistance

The selection of copper for chimney terminations is significantly influenced by its inherent resistance to corrosion, a critical factor given the harsh environmental conditions to which these components are exposed. This characteristic directly impacts the longevity and functionality of the chimney system.

- Natural Oxide Layer Formation

Copper, when exposed to atmospheric elements, develops a protective oxide layer, often referred to as a patina. This layer acts as a barrier, impeding further oxidation and preventing the degradation of the underlying metal. In contrast to ferrous metals, which form rust that accelerates corrosion, the copper oxide layer is self-healing and adheres strongly to the base material, providing long-term protection against environmental contaminants such as acid rain and salt spray.

- Resistance to Flue Gas Condensate

Chimney terminations are subjected to corrosive flue gas condensate, a byproduct of combustion that contains acidic compounds. Copper exhibits a high degree of resistance to these condensates, preventing the internal corrosion that can compromise the structural integrity of the chimney. Alternative materials, like certain grades of steel, may require specialized coatings or linings to achieve comparable levels of protection against flue gas condensate corrosion.

- Mitigation of Electrolytic Corrosion Risks

While copper possesses excellent corrosion resistance, it is crucial to consider the potential for electrolytic corrosion when dissimilar metals are in contact. In instances where copper chimney pots are installed on chimneys with other metallic components, a dielectric barrier is essential to prevent galvanic corrosion. This barrier isolates the copper from less noble metals, thereby mitigating the risk of accelerated corrosion due to electrochemical reactions.

- Enhanced Longevity and Reduced Maintenance

The corrosion resistance of copper directly translates to a significantly extended service life for chimney pots, minimizing the need for frequent repairs or replacements. Structures in coastal areas, subject to high levels of chloride exposure, particularly benefit from this attribute, as the metal’s resistance to salt-induced corrosion maintains structural integrity and aesthetic appeal over prolonged periods.

The inherent corrosion resistance of copper is a key factor in its suitability for chimney pot construction. This attribute minimizes maintenance, enhances safety, and contributes to the long-term performance and aesthetic value of the chimney system. Selecting appropriate materials and employing proper installation techniques are paramount in maximizing the benefits derived from this inherent property of copper.

3. Aesthetic Enhancement

The implementation of copper in chimney termination design significantly contributes to a building’s aesthetic enhancement. The reddish-brown hue of freshly installed copper gradually transitions to a distinctive green patina over time, imbuing structures with a sense of historical character and visual appeal. The selection of copper, therefore, is not merely a functional choice, but a deliberate aesthetic decision impacting the overall architectural statement. Consider, for example, the prevalence of copper chimney pots in historic districts, where their presence reinforces the established architectural vernacular and contributes to the preservation of visual harmony.

The aesthetic benefit of copper chimney pots also stems from their malleability, which allows for the creation of diverse designs and decorative elements. Skilled artisans can craft intricate shapes and patterns that complement various architectural styles, from Victorian to contemporary. This design flexibility allows for a seamless integration of the chimney termination into the building’s overall aesthetic, rather than presenting it as a purely utilitarian component. Furthermore, the reflective qualities of the metal, particularly when newly installed, can enhance the play of light and shadow on the building’s exterior, adding visual interest and sophistication. A practical application of this understanding involves architects specifying particular copper alloys or surface treatments to achieve a desired level of reflectivity or patina development.

In conclusion, the aesthetic enhancement offered by copper chimney pots represents a significant factor in their enduring appeal. The combination of visual character, design flexibility, and reflective properties allows for the creation of chimney terminations that are not only functional but also contribute meaningfully to the overall architectural composition. While other materials may offer similar functional benefits, the unique aesthetic properties of copper remain a distinct advantage, justifying its continued use in discerning architectural projects. Ignoring this aesthetic dimension undervalues the complete potential of copper chimney pots and can result in a less visually compelling building design.

4. Ventilation Efficiency

Ventilation efficiency, concerning chimney systems, directly correlates with the effective removal of combustion byproducts from a structure. Copper chimney pots, owing to their design and material properties, can significantly influence this efficiency.

- Draft Optimization via Design

The design of a copper chimney pot profoundly impacts the draft, which is the force that draws combustion gases up and out of the chimney. Specific designs, such as those incorporating a flared top or strategically placed openings, enhance draft by minimizing downdrafts and optimizing airflow. A well-designed pot promotes efficient ventilation, preventing the backflow of dangerous gases into the living space. For example, a H-style pot can mitigate the effects of wind-induced downdrafts, particularly in exposed locations.

- Material Influence on Temperature

Copper’s thermal properties contribute to ventilation efficiency. The material’s ability to heat up quickly and retain heat helps maintain a consistent flue temperature. A warmer flue promotes a stronger draft, facilitating the upward movement of combustion gases. Conversely, a cold flue can lead to condensation and reduced draft, hindering ventilation efficiency. This is particularly relevant in colder climates, where maintaining flue temperature is critical for effective venting.

- Impact of Internal Diameter and Height

The internal diameter and height of the chimney pot directly influence ventilation. A properly sized diameter ensures adequate airflow without excessive restriction, while an appropriate height creates sufficient stack effect to drive the draft. Undersized pots can restrict airflow, leading to incomplete combustion and the buildup of hazardous gases. Conversely, excessively large pots can cause the flue to cool too rapidly, diminishing draft efficiency. Optimal sizing depends on the appliance being vented and the overall chimney system design.

- Resistance to Corrosion and Blockage

Copper’s inherent corrosion resistance contributes indirectly to ventilation efficiency. By resisting corrosion, the material maintains a smooth internal surface, minimizing friction and promoting unobstructed airflow. Additionally, a well-maintained copper chimney pot is less likely to develop blockages from debris or creosote buildup, which can significantly impede ventilation. Regular inspections and cleaning are essential to preserving optimal ventilation efficiency.

These interrelated facets demonstrate the significant influence of design, material properties, and maintenance practices on the ventilation efficiency of copper chimney pots. Proper consideration of these elements is crucial for ensuring safe and effective venting of combustion byproducts, contributing to both occupant safety and overall building performance. Neglecting these aspects can lead to compromised air quality and potential health hazards.

5. Weather Protection

The capacity of a chimney termination to provide effective weather protection represents a critical performance parameter, influencing not only the longevity of the chimney structure itself but also the integrity of the building it serves. Copper chimney pots, due to their inherent material properties and design flexibility, play a crucial role in mitigating the adverse effects of various weather elements.

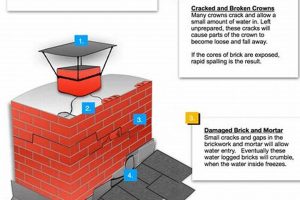

- Rainwater Intrusion Prevention

A primary function of a copper chimney pot is to prevent rainwater from entering the flue. Water ingress can lead to spalling of the internal brickwork, corrosion of metal flue liners, and ultimately, structural damage to the chimney. Specifically designed caps and cowls, fabricated from copper, deflect rainwater away from the flue opening, minimizing water absorption and subsequent damage. For instance, a properly designed copper cap can significantly reduce rainwater entry during heavy rainfall events, preserving the integrity of the chimney structure. This protection extends to the connected heating appliances, preventing water damage to sensitive components.

- Wind-Induced Downdraft Mitigation

Wind interacting with the chimney can create downdrafts, forcing combustion byproducts back into the dwelling. Copper chimney pots equipped with specialized cowls or baffles are designed to disrupt wind patterns and prevent downdrafts. These design elements effectively neutralize the negative pressure created by wind, ensuring the proper and continuous venting of flue gases. This function is particularly critical in areas prone to high winds or turbulent weather conditions, where downdrafts can pose a significant safety hazard. A properly installed copper cowl can significantly improve the draft, especially in windy locations.

- Snow and Ice Accumulation Resistance

In regions experiencing significant snowfall and freezing temperatures, the accumulation of snow and ice on chimney terminations can obstruct the flue, impeding ventilation and potentially causing structural damage. Copper’s relatively high thermal conductivity helps to melt snow and ice accumulation, preventing blockages and maintaining proper draft. Furthermore, the material’s resistance to corrosion ensures that it remains structurally sound even under prolonged exposure to freeze-thaw cycles. The presence of a copper chimney pot can reduce the risk of ice dams forming around the chimney base, safeguarding the roof structure.

- Protection Against Debris Ingress

Chimney pots serve as a barrier against the entry of debris such as leaves, branches, and nesting animals. Debris accumulation within the flue can obstruct ventilation and create a fire hazard. Copper mesh or screens incorporated into the chimney pot design prevent the entry of these foreign materials, maintaining a clear and unobstructed flue passage. This preventative measure minimizes the risk of chimney fires and ensures the safe and efficient operation of the heating appliance. A well-maintained copper screen effectively filters out debris, preserving the integrity of the chimney system.

These multifaceted weather protection features, inherent in well-designed copper chimney pots, contribute significantly to the longevity, safety, and overall performance of the chimney system. By mitigating the adverse effects of rain, wind, snow, ice, and debris, these terminations ensure the reliable and efficient venting of combustion byproducts, safeguarding both the structure and its occupants. Failing to prioritize effective weather protection can result in costly repairs, compromised safety, and reduced heating appliance efficiency.

6. Material Cost

The selection of copper for chimney terminations necessitates careful consideration of material cost, as it represents a significant component of the overall project expenditure. The initial investment for copper is generally higher compared to alternative materials such as galvanized steel or concrete. This cost differential arises from the raw material price, extraction processes, and manufacturing techniques associated with copper production. Consequently, the selection of copper directly impacts budgetary allocations and project feasibility.

Despite the higher upfront cost, a comprehensive evaluation must also account for the long-term economic benefits associated with copper’s durability and corrosion resistance. While the initial expenditure may be substantial, copper’s extended lifespan and reduced maintenance requirements can result in lower total cost of ownership over the product’s operational life. For instance, a building owner opting for a copper chimney pot may avoid frequent replacements and repairs necessitated by corrosion or weathering, as typically experienced with less durable materials. This long-term cost advantage should be factored into the decision-making process, balancing the initial expense with the potential for reduced maintenance and replacement costs.

Ultimately, the decision to utilize copper for chimney terminations involves a trade-off between initial material cost and long-term economic benefits. While the higher upfront expenditure may present a challenge for budget-conscious projects, the superior durability and reduced maintenance requirements of copper can translate into lower overall costs over the lifespan of the chimney system. Therefore, a thorough cost-benefit analysis, considering both immediate expenses and long-term savings, is essential for making an informed decision regarding material selection.

7. Proper Installation

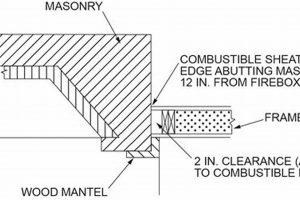

The longevity and efficacy of chimney terminations constructed from copper are inextricably linked to proper installation techniques. Improper installation can negate the inherent benefits of the material, leading to premature failure and compromised performance. A direct cause-and-effect relationship exists: deficiencies in installation, such as inadequate flashing or improper sealing, invariably result in water intrusion, accelerated corrosion, and potential structural damage. For instance, if flashing is not correctly integrated with the roofing material, rainwater can penetrate the chimney chase, causing rot and compromising the structural integrity of both the chimney and the surrounding building elements. The importance of proper installation cannot be overstated, as it serves as the foundation upon which the long-term performance of the copper chimney pot rests.

Real-world examples underscore the practical significance of adherence to established installation protocols. Consider a scenario where a copper chimney pot is secured using fasteners incompatible with copper, leading to galvanic corrosion at the points of contact. This corrosion weakens the joints, eventually resulting in structural failure and necessitating costly repairs. Conversely, instances where skilled professionals meticulously follow best practices, employing appropriate fasteners, proper sealing compounds, and correct flashing techniques, demonstrate the potential for copper chimney pots to provide decades of reliable service. Furthermore, proper installation ensures compliance with relevant building codes and safety standards, mitigating potential liability issues. A properly installed and maintained copper chimney pot is a testament to diligent craftsmanship and adherence to established industry standards.

In conclusion, the benefits associated with copper chimney pots durability, corrosion resistance, and aesthetic appeal are contingent upon proper installation. Neglecting this crucial aspect can negate the advantages of the material, leading to premature failure and compromising the overall performance of the chimney system. Therefore, engaging qualified and experienced professionals, adhering to established installation protocols, and employing appropriate materials are essential for realizing the full potential of copper chimney terminations. This understanding is critical for homeowners, contractors, and architects alike, ensuring that the investment in copper chimney pots yields long-term value and reliable performance.

Frequently Asked Questions

The following questions address common inquiries regarding copper chimney terminations, providing clarity on their selection, installation, and maintenance.

Question 1: What is the expected lifespan of this chimney component?

The service life of a chimney termination fabricated from copper depends on several factors, including material grade, environmental conditions, and maintenance practices. Generally, a properly installed and maintained copper chimney pot can last for 50 years or more. Exposure to harsh coastal environments or neglect of routine maintenance may reduce this lifespan.

Question 2: Does copper chimney pot require special maintenance procedures?

While copper possesses inherent corrosion resistance, routine maintenance is recommended. Regular inspections should be conducted to identify and address any signs of damage or corrosion. Cleaning with appropriate, non-abrasive cleaning agents helps to preserve the aesthetic appeal and prevent the buildup of debris. It is crucial to avoid using harsh chemicals or abrasive scrubbing pads, as these can damage the copper’s protective patina.

Question 3: How does the cost of a copper chimney pot compare to alternatives?

The initial cost of copper chimney pots is typically higher than that of alternatives constructed from materials such as galvanized steel or concrete. However, a cost-benefit analysis should consider the long-term durability and reduced maintenance requirements of copper, which can offset the higher upfront cost over the lifespan of the chimney.

Question 4: Are there specific building codes that govern the installation of a copper chimney pot?

Building codes pertaining to chimney installations vary by jurisdiction. It is essential to consult local building codes and regulations to ensure compliance with all applicable requirements. These codes often address aspects such as chimney height, clearance from combustible materials, and proper flashing techniques. Proper adherence to these codes is crucial for safety and regulatory compliance.

Question 5: Can copper chimney pots be used with any type of fuel-burning appliance?

Copper chimney pots are generally compatible with a wide range of fuel-burning appliances, including wood stoves, gas fireplaces, and oil furnaces. However, specific installation requirements may vary depending on the type of appliance and the characteristics of the flue gases produced. Consult with a qualified chimney professional to determine the suitability of copper for a particular application.

Question 6: What is the purpose of the green patina that forms on copper over time?

The green patina that develops on copper surfaces is a naturally occurring protective layer formed through oxidation. This patina, composed primarily of copper carbonates and sulfates, provides a barrier against further corrosion. It is a stable and durable coating that enhances the material’s longevity and aesthetic appeal. Attempts to remove the patina are generally discouraged, as this can expose the underlying metal to environmental damage.

These answers provide a foundational understanding of the selection, maintenance, and application of metallic chimney terminations. Consulting with qualified professionals is always recommended for specific project requirements.

The following section will delve into the historical significance of utilizing copper in chimney construction.

Copper Chimney Pots

The preceding analysis has illuminated the multifaceted attributes of terminations crafted from copper. Key considerations, ranging from material durability and corrosion resistance to aesthetic enhancement and ventilation efficiency, underscore the complex interplay of factors influencing their selection and application. Proper installation, adherence to building codes, and a thorough understanding of long-term cost implications are essential for realizing the full potential of this material in chimney construction.

The information provided serves as a foundation for informed decision-making. Continued diligence in the application of best practices and ongoing research into material science will further enhance the efficacy and longevity of structures crowned with terminations fashioned from copper. Prudent execution remains paramount for safeguarding structural integrity and ensuring the continued functionality of these essential building components.