A singular covering designed to protect multiple chimney openings, this structure prevents precipitation, debris, and animals from entering the chimney system. These covers often feature a single, larger mesh or solid top that spans across all the flues, differing from individual flue caps designed for single chimney openings. Examples include a custom-fabricated stainless-steel unit for a large, multi-flue chimney and a more standardized, multi-opening cover available in various sizes.

The utilization of such a device contributes significantly to chimney longevity and operational efficiency. By preventing water ingress, it mitigates internal damage caused by freeze-thaw cycles and corrosion. Furthermore, it serves as a barrier against nesting birds and other creatures that can obstruct the flue, leading to potentially dangerous backdrafts and reduced heating system performance. Historically, simpler methods like makeshift boards or rudimentary caps were used, evolving to the more durable and effective modern designs.

Understanding the materials used in construction, installation techniques, and proper sizing is crucial for selecting the appropriate protection for a multi-flue chimney system. This involves evaluating various factors, including local climate conditions, existing chimney structure, and specific venting requirements of the attached appliances.

Installation and Maintenance Tips

The following guidance aids in ensuring optimal performance and longevity of a multi-flue chimney protection system.

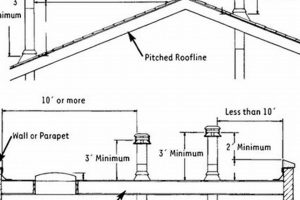

Tip 1: Proper Sizing is Critical: Accurate measurement of the chimney crown and flue extensions is essential. An undersized cover will not adequately protect the chimney, while an oversized one may be unstable and susceptible to wind damage. Consult manufacturer specifications for appropriate dimensions.

Tip 2: Material Selection Matters: Opt for corrosion-resistant materials such as stainless steel or copper. These materials withstand the elements and prolong the cover’s lifespan, particularly in coastal or high-precipitation areas.

Tip 3: Professional Installation Recommended: While DIY installation may seem feasible, professional installation ensures proper anchoring and sealing. Improper installation can lead to cover failure and potential chimney damage.

Tip 4: Regular Inspection for Debris Accumulation: Periodically inspect the cover for leaves, twigs, and other debris that may obstruct airflow. Clear any obstructions to maintain optimal venting efficiency.

Tip 5: Secure Attachment Prevents Displacement: Verify that the cover is securely fastened to the chimney crown. High winds can dislodge a poorly secured cover, rendering it ineffective and potentially creating a safety hazard.

Tip 6: Consider Animal Guards: Ensure the chosen cover incorporates a robust mesh to prevent birds, squirrels, and other animals from entering the chimney. This is particularly important in rural or wooded areas.

Tip 7: Address Chimney Crown Integrity: Before installing a cover, inspect the chimney crown for cracks or deterioration. Repair any damage to ensure a stable base for the cover and prevent water infiltration.

Implementing these tips enhances the protective capabilities and extends the service life of the chimney protection device, preventing costly repairs and ensuring safe operation of the venting system.

Following these guidelines is a prerequisite for achieving the desired outcome.

1. Proper Sizing

The relationship between correct dimensions and a multi-flue chimney protective component is fundamentally deterministic. An improperly sized cover, whether too small or excessively large, negates the device’s intended function. An undersized component fails to fully shield the flues from precipitation, animal intrusion, and debris accumulation. Conversely, an oversized unit can be structurally unstable, susceptible to wind damage, and potentially create hazardous conditions by obstructing proper draft. The effects of incorrect sizing extend beyond mere functionality; they directly influence the long-term structural integrity of the chimney itself. For instance, a cover too small allows water to penetrate the brickwork, leading to freeze-thaw damage and eventual structural degradation. Conversely, an overly large cover, improperly secured, might become a projectile during severe weather events, posing risks to surrounding property.

Accurate measurement and adherence to manufacturer specifications are critical. The internal dimensions of each flue, the overall footprint of the chimney crown, and the height of any protruding flues must be precisely documented. Installation often involves custom fabrication or modification of a standard product to achieve a seamless fit. Practical application is seen in historic preservation projects, where chimneys frequently possess unique dimensions requiring bespoke solutions. Similarly, chimneys serving multiple appliances with varying venting requirements necessitate precise sizing to ensure adequate draft for each flue. Incorrect sizing leads to inefficient combustion and potential carbon monoxide buildup, an outcome directly linked to the quality of installation.

Achieving correct dimensions presents challenges, particularly with older or irregular chimney structures. Overcoming these difficulties requires careful assessment, accurate measurement techniques, and, in many instances, the expertise of a qualified chimney professional. While the benefits of a properly sized cover are readily apparent, the repercussions of neglect extend to safety, property value, and regulatory compliance. In summation, precise sizing is not merely a recommendation but a prerequisite for effective chimney protection.

2. Material Durability

The material composition of a multi-flue chimney cover directly dictates its service life and protective efficacy. The primary function of the covershielding multiple flues from environmental stressorsnecessitates robust materials capable of withstanding prolonged exposure to precipitation, temperature fluctuations, corrosive flue gases, and ultraviolet radiation. Inferior materials degrade rapidly, leading to structural failure, compromised protection, and ultimately, accelerated chimney deterioration. For example, a cover constructed from low-grade galvanized steel will corrode quickly in coastal environments due to salt-air exposure, resulting in rust formation, structural weakening, and eventual perforation, rendering it ineffective. The choice of material, therefore, constitutes a critical design parameter influencing the long-term performance and cost-effectiveness of the cover.

Practical applications emphasize the use of materials such as 304 or 316 stainless steel, copper, or specialized high-temperature alloys. Stainless steel provides excellent resistance to corrosion and oxidation, while copper offers superior longevity and aesthetic appeal. High-temperature alloys are essential when the cover is exposed to excessive heat from improperly functioning appliances or wood-burning stoves. The selection process should consider the specific operating conditions of the chimney, local climate, and potential for chemical exposure. For instance, chimneys venting coal-burning furnaces require covers with enhanced acid resistance due to the higher sulfur content in the exhaust gases. Similarly, chimneys located in areas prone to heavy snowfall demand materials with high yield strength to prevent deformation under load. Neglecting these considerations leads to premature failure and necessitates frequent replacements, increasing maintenance costs and potentially jeopardizing safety.

In conclusion, material durability is not merely an ancillary attribute but a fundamental prerequisite for a functional and reliable multi-flue chimney cover. Selection criteria must prioritize corrosion resistance, temperature stability, and structural integrity based on the specific application and environmental context. While initial cost may be a factor, the long-term benefits of durable materialsreduced maintenance, extended service life, and enhanced protectionoutweigh the expense. Overcoming the challenges associated with material selection requires a thorough understanding of material properties, environmental factors, and chimney operating conditions. Prioritizing material durability ensures optimal chimney protection and minimizes the risk of costly repairs or hazardous conditions.

3. Secure Installation

The integrity of a multi-flue chimney cover fundamentally depends on its secure installation. A compromised installation negates the protective function, rendering the cover vulnerable to displacement by wind, snow, or other external forces. This, in turn, exposes the chimney flues to the elements, defeating the purpose of the cover. For example, a cover loosely attached may become dislodged during a severe storm, allowing rain and debris to enter the chimney, leading to water damage and potential blockages. The relationship between secure installation and cover effectiveness is therefore causal and direct.

Proper installation involves several critical steps: selecting appropriate mounting hardware compatible with the chimney’s construction materials, ensuring a firm and stable attachment to the chimney crown or flue extensions, and applying a weather-resistant sealant to prevent water infiltration at the point of contact. Consider a scenario where a stainless-steel cover is inadequately secured to a brick chimney. Over time, vibrations from wind and temperature fluctuations can loosen the fasteners, creating gaps that allow moisture to penetrate the brickwork, leading to accelerated deterioration. Conversely, a professionally installed cover, properly anchored and sealed, provides lasting protection against the elements and significantly extends the chimney’s lifespan.

In summary, secure installation is an indispensable component of a functional multi-flue chimney cover. The consequences of neglecting this aspect range from reduced protective capacity to potential structural damage. Understanding the principles of secure installation, employing appropriate techniques, and utilizing durable materials are paramount for achieving long-term chimney protection and ensuring safe operation of venting systems.

4. Debris Prevention

Effective debris prevention is a primary function of a multi-flue chimney cover. These protective structures serve to mitigate the accumulation of foreign matter within the chimney system, thereby preserving its operational efficiency and structural integrity. The following facets outline the critical role debris prevention plays in maintaining a functional and safe chimney.

- Leaf and Twig Accumulation

Chimney flues, absent protective measures, act as collection points for leaves, twigs, and other organic debris carried by wind. This accumulation restricts airflow, reducing the venting capacity of the chimney and potentially leading to backdrafting of combustion gases. A well-designed cover prevents such entry, maintaining unobstructed passage for exhaust.

- Animal Nesting Deterrence

Open chimney flues offer attractive nesting sites for birds, squirrels, and other small animals. Nests constructed within the flue can completely block the passage, posing a significant fire hazard and potentially introducing harmful pathogens into the dwelling. The presence of a cover with a properly sized mesh effectively deters animal entry, safeguarding the chimney from these obstructions.

- Mortar and Brick Degradation Prevention

Debris accumulation can accelerate the deterioration of chimney materials. Organic matter retains moisture, promoting freeze-thaw cycles that weaken mortar joints and cause brick spalling. A clean, debris-free chimney is less susceptible to these destructive forces, extending its lifespan and reducing maintenance costs. The covers offer an increase level of protection and support for the other prevention factor.

- Snow and Ice Infiltration Reduction

While technically precipitation, snow and ice entering a chimney flue contribute to debris-related issues. Melting snow and ice saturate creosote deposits, creating a corrosive sludge that damages flue liners and promotes structural decay. Additionally, ice buildup can constrict the flue opening, impeding draft. Effective covers shield the flues from direct snow and ice infiltration, mitigating these problems.

These facets illustrate the integral role debris prevention plays in the overall functionality and longevity of a multi-flue chimney system. By effectively mitigating the accumulation of foreign matter, a well-designed and properly installed chimney cover preserves venting efficiency, protects against fire hazards, and minimizes structural damage. The cumulative effect of these benefits underscores the importance of debris prevention as a fundamental aspect of chimney maintenance.

5. Animal Deterrence

Effective animal deterrence is a crucial function of a multi-flue chimney cover. Open chimney flues present readily accessible nesting locations for various animals, most commonly birds, squirrels, and raccoons. The construction of nests within these flues causes significant obstructions to proper venting, potentially leading to dangerous carbon monoxide buildup within the dwelling. A multi-flue chimney cover equipped with an appropriate mesh or screening system physically prevents these animals from entering, mitigating the associated safety hazards and operational inefficiencies. For instance, the complete blockage of a flue by a bird’s nest can force exhaust gases back into the living space, creating a potentially lethal environment. Therefore, the presence of a robust animal deterrence system is not merely an optional feature, but a fundamental component of a properly functioning protective device.

The practical application of animal deterrence in chimney cover design involves careful consideration of mesh size and material durability. The mesh must be small enough to exclude even the smallest animals, such as sparrows or starlings, while simultaneously maintaining adequate airflow. Stainless steel mesh is commonly employed due to its resistance to corrosion and physical damage from persistent animals. Furthermore, the attachment of the mesh to the cover must be robust to prevent animals from dislodging it, thus compromising its effectiveness. Regular inspection and maintenance are also critical to ensure that the mesh remains intact and free from damage or obstruction. A compromised mesh, even with a small hole, can allow animals to gain entry, negating the intended protection.

In summary, animal deterrence is an indispensable aspect of multi-flue chimney cover design and functionality. The consequences of neglecting this feature range from reduced venting efficiency to increased safety risks. Understanding the principles of effective animal deterrence, selecting appropriate materials and designs, and maintaining the integrity of the protective barrier are paramount for ensuring long-term chimney protection and safeguarding the well-being of occupants. The integration of animal deterrence is thus not simply a design consideration, but a crucial safety measure.

6. Crown integrity

The structural integrity of the chimney crown is inextricably linked to the functionality and longevity of any multi-flue chimney cover. The crown, the topmost portion of the chimney, serves as the foundation upon which the cover rests and provides a crucial barrier against water intrusion. A compromised crown, characterized by cracks, spalling, or deterioration, undermines the effectiveness of even the most robust cover. For example, a cracked crown allows water to penetrate the chimney structure, leading to freeze-thaw damage that progressively weakens the masonry. This moisture also accelerates corrosion of the flue liners and reduces the efficiency of the venting system. Installing a multi-flue chimney cover on a damaged crown without addressing the underlying issues merely masks the problem and may exacerbate the deterioration process. The structural weaknesses will eventually undermine both the chimney and the multi-flue chimney cover.

Practical application dictates that a thorough inspection of the chimney crown should precede the installation of any multi-flue cover. Any existing damage must be repaired or remediated to ensure a stable and watertight base for the cover. This may involve patching cracks, applying a waterproof sealant, or, in severe cases, completely rebuilding the crown. Failing to address crown integrity can lead to water pooling on the damaged surface, creating an ideal environment for ice formation and further structural damage during winter months. Additionally, a weakened crown cannot provide adequate support for the cover, increasing the risk of displacement during high winds or seismic activity. Therefore, the selection and installation of a multi-flue chimney cover must be considered as part of a comprehensive chimney maintenance strategy that prioritizes the integrity of the crown.

In conclusion, maintaining the structural integrity of the chimney crown is essential for the effective performance of a multi-flue chimney cover. A compromised crown negates the protective benefits of the cover and accelerates chimney deterioration. Addressing crown damage through proper repair techniques prior to cover installation is a critical step in ensuring the long-term health and functionality of the entire chimney system. This proactive approach not only protects the chimney from the elements but also safeguards the dwelling and its occupants from potential hazards associated with a damaged or failing chimney.

7. Draft Optimization

Draft optimization, the process of ensuring adequate and consistent airflow through a chimney, is intrinsically linked to the design and implementation of a multi-flue chimney cover. The cover must not impede the natural drafting process; rather, it should facilitate it by preventing downdrafts and maintaining stable internal air pressure. A poorly designed cover can restrict airflow, leading to incomplete combustion, carbon monoxide buildup, and reduced heating appliance efficiency. Conversely, a properly designed cover enhances draft by shielding the flues from adverse wind conditions and preventing the entry of precipitation, which can dampen the flue and reduce draft effectiveness. The cause-and-effect relationship is evident: improper cover design directly impairs draft, while optimized design promotes it. A real-world example is a multi-flue chimney serving both a furnace and a fireplace; a cover obstructing draft could cause the furnace to operate inefficiently and the fireplace to produce excessive smoke within the living space. Recognizing this connection is paramount for safe and effective chimney operation.

The importance of draft optimization as a component of multi-flue chimney cover design extends beyond safety and efficiency. Optimal draft contributes to the longevity of the chimney structure itself. Proper venting reduces the accumulation of creosote in wood-burning systems and minimizes the corrosive effects of combustion gases on the flue liners. A cover that facilitates draft helps to expel moisture, preventing freeze-thaw damage to the masonry. This practical significance is demonstrated in older buildings, where chimneys are often subjected to prolonged exposure to the elements; a properly optimized cover significantly extends the lifespan of these structures, preventing costly repairs. The design must accommodate the specific venting requirements of each appliance served by the chimney, considering factors such as flue size, height, and exhaust temperature.

In conclusion, draft optimization is not merely an ancillary consideration but an essential element of multi-flue chimney cover design. Understanding the delicate balance between protection and airflow is crucial for ensuring safe, efficient, and long-lasting chimney performance. Challenges arise when retrofitting covers to existing chimneys with pre-existing draft issues, requiring careful assessment and potentially necessitating modifications to the cover design. By prioritizing draft optimization, professionals can deliver solutions that not only protect the chimney but also enhance the overall performance of the attached heating appliances.

Frequently Asked Questions About Multi Flue Chimney Covers

The following section addresses commonly asked questions concerning multi-flue chimney covers, providing concise and informative answers to aid in understanding their purpose, selection, and maintenance.

Question 1: What constitutes a multi-flue chimney cover?

A multi-flue chimney cover is a protective structure designed to span and safeguard multiple chimney flues simultaneously, as opposed to individual caps installed on each flue. These covers prevent the ingress of precipitation, debris, and animals into the chimney system.

Question 2: Why is a multi-flue chimney cover necessary?

The implementation of a multi-flue chimney cover mitigates water damage, prevents flue blockages from debris and animal nesting, and enhances overall chimney longevity. Unprotected flues are susceptible to environmental damage and obstruction.

Question 3: What materials are recommended for multi-flue chimney covers?

Durable, corrosion-resistant materials such as stainless steel or copper are preferred. These materials withstand harsh weather conditions and provide extended service life compared to less robust alternatives.

Question 4: How is the appropriate size for a multi-flue chimney cover determined?

Accurate measurements of the chimney crown and flue extensions are crucial. The cover must adequately span all flues without being excessively large or unstable. Consultation with manufacturer specifications is advised.

Question 5: Is professional installation required for a multi-flue chimney cover?

Professional installation is strongly recommended to ensure proper anchoring and sealing. Improper installation can compromise the cover’s effectiveness and potentially damage the chimney structure.

Question 6: What maintenance is required for a multi-flue chimney cover?

Periodic inspection for debris accumulation and secure attachment verification are essential. Clearing obstructions and ensuring the cover remains firmly anchored maintains optimal performance.

In summary, the selection and maintenance of a multi-flue chimney cover are critical aspects of chimney care. Proper implementation ensures protection, efficiency, and longevity of the chimney system.

Consult a qualified chimney professional for further guidance or specialized assistance.

Conclusion

This exploration has outlined the critical role a multi flue chimney cover plays in protecting and maintaining chimney systems. The discussion has emphasized the importance of proper sizing, durable materials, secure installation, debris and animal prevention, crown integrity, and draft optimization. Each aspect contributes significantly to the overall performance and longevity of the chimney, safeguarding the structure from environmental damage and operational inefficiencies.

The implementation of a multi flue chimney cover represents a proactive measure in preserving the integrity of a vital building component. Understanding the principles of selection, installation, and maintenance is paramount for ensuring safe and effective operation. Continued vigilance and adherence to best practices will contribute to the long-term health and performance of chimney systems, preventing costly repairs and potential hazards.