The component involved in creating a watertight seal where a chimney structure intersects with a roof plane is vital for preventing water intrusion. This often involves thin pieces of impervious material, typically metal, strategically installed to divert water away from vulnerable areas. For example, sections are often bent and layered to create a barrier against rain and snow, directing runoff down and away from the chimney base.

Effective moisture management at the roof-chimney interface preserves the structural integrity of both the chimney and the roof. Failure of this protective barrier can lead to costly repairs, including rot, mold growth, and compromised structural support. Historically, materials like lead were used, reflecting the enduring need for reliable weatherproofing in these areas.

Subsequent discussions will delve into materials commonly employed, installation techniques considered best practices, common failure points, and preventative maintenance strategies aimed at extending its lifespan and performance.

Essential Guidance for Chimney Weatherproofing

Proper weatherproofing at the chimney-roof intersection is critical for maintaining structural integrity and preventing water damage. The following guidelines outline key considerations for ensuring its effectiveness and longevity.

Tip 1: Material Selection: Choose durable, corrosion-resistant materials compatible with both the chimney and roofing materials. Common options include aluminum, copper, and stainless steel, each offering varying levels of protection and longevity. Evaluate the specific environmental conditions to determine the most appropriate choice.

Tip 2: Proper Installation: Adhere strictly to industry best practices during installation. This includes overlapping pieces correctly, ensuring a tight seal against both the chimney and roofing surfaces, and using appropriate fasteners. Professional installation is highly recommended to ensure proper execution.

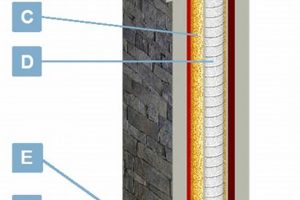

Tip 3: Step Installation: Employ the step method effectively where the chimney runs parallel to the roof slope. Individual pieces are bent and installed in overlapping layers, following the contours of the roofing material to create a continuous, watertight barrier.

Tip 4: Counter Types: Implement this type where the chimney intersects the roof at an angle. This involves embedding into the chimney mortar joints and overlapping the base flashing, providing a secure and weatherproof seal.

Tip 5: Regular Inspection: Conduct routine inspections to identify any signs of damage or deterioration, such as cracks, rust, or loose components. Early detection allows for timely repairs, preventing more extensive and costly issues down the line.

Tip 6: Sealant Application: Apply high-quality sealant along all seams and edges to provide an additional layer of protection against water intrusion. Choose a sealant specifically designed for exterior use and compatible with the materials involved. Reapply sealant as needed, based on the manufacturer’s recommendations.

Tip 7: Mortar Joint Maintenance: Inspect the mortar joints around the chimney base regularly. Cracks or crumbling mortar can compromise the integrity of the installation. Address any mortar issues promptly with repointing to maintain a solid and watertight structure.

Implementing these practices will significantly enhance the effectiveness of the protective barrier, minimizing the risk of water damage and preserving the structural integrity of the chimney and roof.

The subsequent sections will delve into more detailed explanations of specific materials, advanced installation techniques, and troubleshooting common problems encountered with chimney weatherproofing.

1. Material Durability

The longevity and effectiveness of chimney weatherproofing are intrinsically linked to the inherent properties of the materials employed. The selection of materials directly impacts its ability to withstand environmental stressors, including thermal expansion and contraction, exposure to ultraviolet radiation, and prolonged contact with moisture. Premature failure due to material degradation negates even the most meticulous installation practices. For example, the use of galvanized steel in regions with high acid rain concentrations will lead to accelerated corrosion, resulting in leaks and compromised weather protection within a relatively short timeframe. Conversely, the selection of copper or stainless steel demonstrates a proactive approach to material durability, offering superior resistance to corrosion and extending the operational life of the system.

The causal relationship between material degradation and subsequent water damage is well-documented. When inferior materials fail, the primary defense against water penetration is compromised, leading to potential structural damage to both the chimney and the adjacent roof. This can manifest as rot within wooden framing, staining on interior surfaces, and the growth of mold and mildew, all of which necessitate costly remediation. Selecting a material with a proven track record of durability, appropriate for the specific climate and environmental conditions, is therefore paramount to preventing these adverse outcomes. Consider the comparative performance of aluminum versus copper in coastal environments; while aluminum may offer initial cost savings, its susceptibility to galvanic corrosion in the presence of salt air often results in a significantly shorter service life compared to copper.

In summation, material durability is not merely a desirable attribute but an essential prerequisite for effective chimney weatherproofing. Choosing appropriate materials, taking into account regional climatic factors and potential corrosive agents, directly influences the long-term performance and reliability of the entire system. Failing to prioritize material durability creates a vulnerability that can lead to costly repairs, structural damage, and compromised indoor air quality. Addressing this issue requires a thorough understanding of material properties and a commitment to selecting options designed to withstand the specific challenges presented by the local environment.

2. Installation Technique

The effectiveness of chimney weatherproofing is inextricably linked to the execution of the installation process. Regardless of the quality of materials employed, deficient installation techniques compromise the integrity of the system, rendering it vulnerable to water intrusion. Proper installation ensures a secure and watertight seal between the chimney structure and the roofing material, effectively diverting water away from susceptible areas. Conversely, errors such as inadequate overlapping, improper fastening, or the failure to create a continuous barrier can create pathways for water penetration, ultimately leading to structural damage.

Consider the step method, a common technique used where the chimney runs parallel to the roof slope. If the individual pieces are not precisely bent and layered, gaps can form, allowing water to seep behind the system and into the building’s interior. Similarly, with counter flashing, improper embedment into the chimney’s mortar joints undermines its ability to effectively direct water runoff. A real-world example illustrates this point: numerous instances of water damage attributed to improperly installed flashing revealed gaps in the step system caused by insufficient overlap and the use of incorrect fastener types. In these cases, the initial cost savings from a less experienced installer were quickly overshadowed by the expenses associated with extensive repairs.

In conclusion, mastering and consistently applying correct installation techniques is not merely a procedural formality but a fundamental requirement for effective chimney weatherproofing. A thorough understanding of best practices, coupled with meticulous execution, is essential for ensuring the long-term performance and reliability of the system. Prioritizing skilled installation minimizes the risk of water damage and contributes significantly to the overall structural integrity of the building. Continued education and adherence to industry standards are, therefore, crucial for all professionals involved in chimney maintenance and repair.

3. Water Diversion

The primary function of chimney weatherproofing is the effective management of water runoff, preventing its ingress into the building structure. Water diversion, in this context, defines the methods and mechanisms by which precipitation is channeled away from vulnerable intersections, safeguarding the integrity of both the chimney and the roofing system.

- Material Overlap and Slope

Strategic overlapping of materials, typically metal sheets, creates a cascading effect that forces water to flow downwards and outwards. The angle of overlap and the overall slope dictate the efficiency of water redirection. Insufficient overlap or an inadequate slope can lead to water pooling and eventual penetration. A common example is the use of step flashing where each piece overlaps the next and is integrated with the roofing shingles, ensuring a positive drainage path away from the chimney’s sides.

- Drip Edges and Diverters

Drip edges and specialized diverters are designed to prevent water from running back towards the chimney’s surface or seeping underneath the protective barrier. These components extend slightly beyond the edge of the system, causing water to drip off rather than adhering to the structure. An effective drip edge is often bent outwards at a slight angle, maximizing its ability to shed water and minimizing the risk of water damage to the underlying materials.

- Counter Flashing Integration

Counter flashing, embedded into the chimney’s mortar joints, forms a critical component of the water diversion strategy. By overlapping the base, it creates a two-tiered defense against water intrusion, preventing water from penetrating the joint between the system and the chimney. Correct integration requires precise cutting and embedding of the counter flashing, ensuring a tight seal and preventing water from migrating behind the system.

- Sealant Application and Maintenance

The application of high-quality sealant along seams and edges provides an additional layer of protection against water penetration. The sealant fills any minor gaps or irregularities, creating a watertight barrier. Regular inspection and maintenance of sealant are essential, as weathering and degradation can compromise its effectiveness over time. Reapplication of sealant, as needed, maintains the integrity of the water diversion system.

These elements, working in concert, create a comprehensive water management strategy for chimneys. The effectiveness hinges on meticulous design, proper installation, and ongoing maintenance. Failure to adequately address water diversion leads to predictable consequences: water damage, structural deterioration, and compromised indoor air quality. Consequently, a robust water diversion system is a cornerstone of chimney weatherproofing, ensuring the long-term integrity and performance of the structure.

4. Seal Integrity

Seal integrity, in the context of chimney weatherproofing, refers to the sustained effectiveness of the barrier preventing water from penetrating the intersection between the chimney structure and the roofing material. This encompasses the properties of materials, the precision of installation, and the ongoing maintenance required to ensure a continuous and impermeable barrier. The absence of seal integrity directly leads to water infiltration, which can subsequently cause structural damage, mold growth, and compromised indoor air quality. The system, therefore, is only as effective as its capacity to maintain a watertight seal over time.

The materials composing the system, such as metal, sealants, and fasteners, must be selected for their inherent resistance to degradation and their compatibility with each other. Consider the use of dissimilar metals; galvanic corrosion can occur, compromising the seal where these materials interface. The sealant, often applied at critical joints and seams, must maintain its elasticity and adhesion despite temperature fluctuations and exposure to UV radiation. Sealant failure, whether through cracking, peeling, or loss of adhesion, is a common point of water entry. Furthermore, the correct installation technique is paramount to achieving initial seal integrity. For instance, a step that is not properly integrated with the roofing shingles will create a pathway for water to flow behind the flashing and into the structure. Regular inspection and prompt repair of any breaches in the seal are crucial for preventing water damage.

In summary, seal integrity represents a non-negotiable aspect of effective chimney weatherproofing. The careful selection of compatible and durable materials, the precise execution of installation techniques, and the implementation of a regular maintenance program are essential for ensuring long-term performance. Compromised seal integrity inevitably leads to water damage, highlighting the practical significance of prioritizing this aspect in all chimney-related construction and maintenance activities. A proactive approach to maintaining seal integrity mitigates the risks associated with water penetration, preserving the structural integrity of the chimney and the adjacent building components.

5. Corrosion Resistance

Corrosion resistance is a critical material property that directly impacts the longevity and performance of chimney weatherproofing. The materials used in this application are constantly exposed to environmental elements, including moisture, atmospheric pollutants, and varying temperatures, which can accelerate corrosive processes. The selection of corrosion-resistant materials, therefore, is paramount to preventing premature failure and ensuring long-term protection against water intrusion. When materials susceptible to corrosion are used, the system’s integrity is compromised, leading to leaks, structural damage, and costly repairs. For example, using standard steel can lead to rust and eventually compromise the structural integrity of the system leading to water damage.

The effects of corrosion on chimney systems can be observed in various forms, including rust formation on steel components, pitting on aluminum surfaces, and the breakdown of protective coatings. These processes weaken the materials, creating pathways for water to penetrate the building envelope. The choice of materials with inherent corrosion resistance, such as stainless steel, copper, or certain alloys, is essential for mitigating these risks. Furthermore, proper surface treatments and protective coatings can enhance the corrosion resistance of less inherently durable materials. Maintenance practices, such as regular cleaning and the application of corrosion inhibitors, can further extend the lifespan of the chimney’s weatherproofing. Consider the difference between using galvanized steel and copper in a coastal environment; the salt air rapidly corrodes galvanized steel while copper forms a protective patina, significantly extending its lifespan.

In conclusion, prioritizing corrosion resistance in the selection and maintenance of chimney systems is a fundamental aspect of ensuring their long-term functionality. The use of appropriate materials, coupled with proactive maintenance practices, safeguards against premature failure and protects the building structure from water damage. Recognizing the interconnectedness of material properties, environmental factors, and maintenance procedures is essential for achieving optimal corrosion resistance and maximizing the lifespan of chimney weatherproofing.

6. Code Compliance

Adherence to building codes is paramount in chimney construction and maintenance, particularly concerning the installation of flashing. These regulations are designed to ensure safety, durability, and water resistance, minimizing the risk of structural damage and fire hazards. Compliance is not merely a procedural formality but a critical safeguard for building occupants and property.

- Material Specifications and Standards

Building codes often stipulate the types of materials permitted for use, specifying minimum requirements for corrosion resistance, fire resistance, and weatherability. For instance, codes may mandate the use of specific grades of stainless steel or copper for flashing in certain geographic regions prone to extreme weather conditions. The selection of compliant materials ensures that the flashing can withstand environmental stressors and maintain its protective function over time.

- Installation Procedures and Techniques

Codes dictate the methods and techniques required for the proper installation. This includes requirements for overlapping, fastening, and sealing the flashing to create a watertight barrier. For example, regulations may specify the minimum overlap distance between pieces or the type of sealant required for specific materials. Adhering to these installation standards ensures that the flashing is properly integrated with both the chimney and the roofing system, preventing water penetration.

- Inspection and Enforcement

Building codes typically include provisions for inspection and enforcement to verify compliance with regulations. Building inspectors may examine the materials used, the installation techniques employed, and the overall integrity of the system to ensure it meets code requirements. Failure to comply with code regulations can result in fines, delays, or even the rejection of the construction project. Regular inspections and diligent enforcement are essential for maintaining consistent adherence to code standards.

- Fire Safety Regulations

Chimney-related fire safety is a central concern in building codes. Flashing must be installed in a manner that prevents combustible materials, such as wood framing, from coming into direct contact with the chimney’s heat source. Codes may specify minimum clearance distances and require the use of fire-resistant materials in proximity to the chimney. Compliance with fire safety regulations minimizes the risk of chimney fires and protects the building and its occupants from potential harm.

The preceding facets highlight the essential role of code compliance in chimney flashing. Strict adherence to these regulations, encompassing material specifications, installation procedures, inspection protocols, and fire safety measures, ensures the structural integrity and safety of buildings. Prioritizing code compliance is not only a legal obligation but also a prudent investment in the long-term performance and safety of chimney systems.

7. Mortar Condition

The state of mortar joints surrounding a chimney directly influences the performance and longevity of its associated flashing. Compromised mortar undermines the structural integrity of the chimney and creates pathways for water intrusion, ultimately negating the effectiveness of even the most meticulously installed system. Proper maintenance and timely repair of mortar joints are therefore essential for maintaining optimal flashing performance.

- Water Penetration Pathways

Cracked or crumbling mortar joints provide direct routes for water to penetrate the chimney structure, bypassing the protective barrier. Water intrusion can then lead to internal damage, including deterioration of the chimney liner, damage to adjacent building materials, and the growth of mold and mildew. Effective systems rely on sound mortar joints to create a solid, waterproof base. The absence of this base renders the protective barrier largely ineffective. For instance, consider a chimney with significant mortar deterioration; even if new is installed, water can seep through the compromised mortar joints and compromise the system.

- Compromised Counter Flashing Integration

Counter is typically embedded into the mortar joints of a chimney. Deteriorated mortar makes proper embedment difficult, if not impossible, resulting in a weakened seal between the and the chimney structure. This compromised seal allows water to seep behind the flashing, negating its protective function. When mortar deteriorates, the counter becomes loose, creating a direct pathway for water to enter the building envelope.

- Structural Instability

Extensive mortar deterioration can compromise the structural stability of the chimney itself. This instability can lead to shifting or settling of the chimney, which, in turn, can damage the flashing and create gaps that allow water to enter. A structurally sound chimney is essential for maintaining the integrity of the system. If the chimney is unstable, the will inevitably fail, regardless of the quality of materials or installation techniques used.

- Accelerated Deterioration

Water intrusion caused by deteriorated mortar can accelerate the deterioration of both the mortar itself and the flashing materials. Freeze-thaw cycles exacerbate the cracking and crumbling of mortar, while prolonged exposure to moisture can corrode metal materials. This creates a feedback loop, where water intrusion leads to further deterioration, ultimately compromising the entire system. Regular inspection and prompt repair of mortar joints are essential for preventing this cycle of accelerated deterioration.

In conclusion, the relationship between mortar condition and system performance is undeniable. Maintaining sound mortar joints is a prerequisite for ensuring the long-term effectiveness of the flashing, protecting the chimney and the building from water damage. Regular inspections, timely repairs, and the use of appropriate mortar materials are essential for preserving the integrity of the system and preventing costly repairs.

Frequently Asked Questions About Chimney Flashing

This section addresses common inquiries regarding chimney flashing, providing concise and informative answers to promote a comprehensive understanding of its purpose and maintenance.

Question 1: What is the primary function of flashing on a chimney?

Its principal role is to create a watertight seal where the chimney intersects the roof, preventing water from entering the building structure. This protective barrier is crucial for avoiding structural damage and mold growth.

Question 2: What materials are commonly used for chimney flashing?

Common materials include aluminum, copper, and stainless steel. The selection depends on factors such as cost, durability requirements, and compatibility with existing roofing materials.

Question 3: How often should chimney flashing be inspected?

Routine inspections should be conducted at least annually, preferably in the spring and fall, to identify any signs of damage, corrosion, or deterioration.

Question 4: What are the common signs of flashing failure?

Indicators of failure include rust, cracks, loose components, water stains on interior walls or ceilings near the chimney, and visible gaps between the chimney and the roofing material.

Question 5: Can flashing repair be a do-it-yourself project?

While minor repairs may be possible for experienced homeowners, complex repairs or installations are best left to qualified professionals. Improper installation can exacerbate existing problems and lead to more extensive damage.

Question 6: How does mortar condition affect flashing performance?

Deteriorated mortar joints compromise the integrity of the system, creating pathways for water intrusion. Maintaining sound mortar joints is essential for the system’s long-term effectiveness.

Regular maintenance and timely repairs are vital for ensuring its continued effectiveness in protecting the building from water damage. Neglecting maintenance can lead to costly repairs and structural problems.

The subsequent section will explore advanced troubleshooting techniques for identifying and resolving complex flashing issues.

Flashing on Chimney

The preceding discussion has underscored the multifaceted importance of flashing on chimney structures. Effective weatherproofing requires meticulous attention to material selection, installation techniques, and ongoing maintenance. Neglecting any of these critical elements compromises the system’s integrity, leading to potentially severe consequences for the building’s structural health and occupant well-being.

Ensuring the proper installation and maintenance of flashing on chimney systems is not merely a matter of routine upkeep; it represents a proactive investment in the long-term preservation of property. Building owners and professionals alike must prioritize these systems to mitigate the risks associated with water damage and maintain the structural integrity of buildings for years to come.

![Why Chimney Birds Matter: [Chimney Bird] Care Tips Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Why Chimney Birds Matter: [Chimney Bird] Care Tips | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/03/th-25-300x200.jpg)