Specialized tools and chemical treatments designed for the maintenance and cleaning of chimneys constitute an essential category for ensuring safe and efficient fireplace and heating system operation. These items facilitate the removal of creosote, soot, and other debris that accumulate within chimney flues. Accumulation of these substances not only reduces the efficiency of the venting system but also presents a significant fire hazard.

Proper chimney maintenance, facilitated by the use of appropriate equipment and materials, offers several critical benefits. Regular cleaning reduces the risk of chimney fires, improving the safety of the structure and its occupants. Moreover, clean chimneys allow for optimal airflow, enhancing the efficiency of heating systems, potentially leading to reduced fuel consumption and lower energy costs. Historically, specialized instruments have evolved from simple brushes to sophisticated power sweeping systems to meet the challenges of diverse chimney designs and heating technologies.

The following discussion will delve into the various categories of implements and solutions available for chimney maintenance, highlighting their specific applications, advantages, and proper usage techniques for effective and safe chimney care.

Effective Chimney Maintenance Guidelines

Adhering to consistent chimney maintenance procedures enhances safety and optimizes heating system functionality. The following guidelines outline essential practices for effective chimney care.

Tip 1: Schedule Regular Inspections. Employ a certified professional to conduct annual chimney inspections. These assessments identify structural damage, creosote buildup, and potential hazards requiring attention.

Tip 2: Prioritize Creosote Removal. Implement consistent creosote removal protocols. Creosote accumulation, a highly flammable byproduct of combustion, poses a significant fire risk. Utilize appropriate brushes and cleaning solutions to mitigate this hazard.

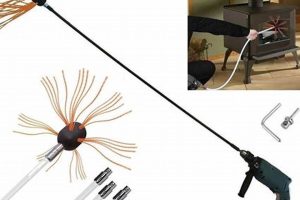

Tip 3: Select Appropriate Cleaning Tools. Utilize tools designed for the specific chimney type and construction material. Employing the wrong equipment may damage the flue lining or compromise its structural integrity.

Tip 4: Understand Brush Selection Criteria. Choose a chimney brush of the correct size and material. Metal brushes are suitable for masonry chimneys, while softer materials are preferred for metal flues to prevent scratching or damage.

Tip 5: Employ Chemical Treatments Judiciously. Utilize chemical creosote modifiers with caution, adhering strictly to manufacturer instructions. These compounds can assist in loosening creosote deposits but do not replace mechanical cleaning.

Tip 6: Implement Cap Maintenance. Ensure the chimney cap remains intact and free from obstructions. A properly functioning cap prevents water intrusion, debris accumulation, and animal nesting, all of which can impede chimney performance.

Tip 7: Document Maintenance Activities. Maintain a record of all chimney maintenance activities, including inspection reports, cleaning dates, and repairs performed. This documentation assists in tracking chimney health and identifying potential long-term issues.

Consistent application of these practices minimizes fire hazards, improves heating system efficiency, and extends the lifespan of the chimney structure.

The subsequent sections will address specialized maintenance techniques and emerging technologies in chimney care, providing a comprehensive overview of the field.

1. Brush Size

The selection of an appropriate brush size is a critical determinant of the efficacy of any chimney sweeping operation. Incorrect brush sizing can result in inadequate cleaning, potential damage to the chimney structure, or inefficient use of resources. Selecting the proper dimensions ensures thorough removal of creosote and soot accumulation.

- Flue Dimension Matching

The brush must correspond directly to the internal dimensions of the chimney flue. An oversized brush becomes difficult to maneuver, increasing the likelihood of becoming lodged within the flue. Conversely, an undersized brush will not effectively contact the flue walls, leaving behind potentially hazardous deposits. Measurements must be precise to ensure optimal contact and cleaning.

- Shape Considerations

Chimney flues are not uniformly round or square. Some may be oval, rectangular, or irregular in shape. The brush shape must accommodate these variations. For example, a square brush is suitable for a square flue, while a round brush is appropriate for a circular one. Using the wrong shape can lead to incomplete cleaning in corners and along edges.

- Material Compatibility

Brush material selection is partially dictated by brush size. Larger brushes, especially those used in industrial or commercial settings, may require more rigid materials to maintain structural integrity. Smaller brushes, designed for residential use, can often utilize more flexible materials that allow for greater maneuverability within confined spaces. The material must also be compatible with the flue lining material to prevent scratching or damage.

- Flexibility and Reach

Brush size impacts the flexibility of the cleaning system. Larger diameter brushes often require more robust and less flexible connecting rods. Smaller brushes can be attached to more flexible rods, allowing access to chimneys with bends or offsets. The trade-off between brush size and system flexibility must be carefully considered based on the specific chimney configuration.

The selection of a brush that is both appropriately sized and shaped for the specific chimney flue is a prerequisite for effective and safe chimney maintenance. Failure to address this core aspect of chimney sweep protocols can compromise the entire cleaning process and potentially increase the risk of chimney fires or structural damage. Ultimately, professional assessment and adherence to industry best practices are essential for informed decision-making in this area.

2. Rod Flexibility

Rod flexibility constitutes a critical performance attribute of chimney sweep products, directly impacting the accessibility and thoroughness of chimney cleaning procedures. The design and material composition of chimney sweep rods dictate their ability to navigate bends, offsets, and complex flue geometries. Insufficient flexibility restricts access, limiting the removal of creosote and soot from critical areas within the chimney system. Conversely, excessive flexibility reduces control and force application, diminishing cleaning effectiveness. Thus, optimal rod flexibility represents a carefully calibrated balance between maneuverability and structural integrity.

The practical implications of rod flexibility are evident in diverse chimney configurations. Older homes often feature chimneys with irregular shapes and sharp angles, demanding highly flexible rods capable of adapting to these contours. Modern chimney designs, while typically more standardized, may still incorporate offsets or bends to accommodate architectural constraints. In such cases, the choice of rods with appropriate flexibility becomes essential for reaching all sections of the flue. Incorrect rod selection, based on insufficient flexibility, can lead to localized creosote buildup, increasing the risk of chimney fires and compromising the venting efficiency of heating appliances. The material of the rod also plays a factor. Fiberglass or nylon rods are flexible for narrower openings, while steel rods offer greater rigidity and are more apt to deal with wider or taller structures.

The selection of chimney sweep products that incorporate appropriate rod flexibility is paramount for ensuring comprehensive chimney maintenance and mitigating safety hazards. Understanding the relationship between rod characteristics and chimney design enables informed decision-making, promoting effective cleaning and long-term chimney health. Challenges remain in standardizing flexibility ratings and educating users on optimal rod selection for specific chimney types. Nevertheless, recognizing the practical significance of rod flexibility is a crucial step toward enhancing the safety and efficiency of chimney sweeping practices.

3. Creosote Remover

Creosote remover represents a critical subcategory within chimney sweep products, addressing the inherent hazards associated with creosote accumulation in chimney flues. Its purpose is to mitigate the risk of chimney fires and improve the overall efficiency of venting systems by facilitating the removal or modification of creosote deposits.

- Chemical Composition and Action

Creosote removers typically consist of chemical compounds formulated to alter the physical properties of creosote. These agents may function by dehydrating, oxidizing, or chemically modifying the creosote, rendering it more brittle and easier to dislodge through mechanical sweeping. For instance, certain removers contain metallic catalysts that promote the conversion of creosote into less flammable substances during combustion. The specific chemical composition and mode of action vary depending on the product formulation and intended application.

- Application Methods

Creosote removers are available in various forms, including powders, liquids, and pre-packaged logs. Powdered removers are typically introduced directly into the firebox during active burning, allowing the chemical vapors to ascend through the chimney flue and interact with the creosote deposits. Liquid removers may be sprayed or brushed onto the flue walls, while creosote-removing logs are designed to be burned as a supplemental fuel source, releasing chemical agents during combustion. The appropriate application method depends on the chimney type, level of creosote buildup, and product specifications.

- Limitations and Safety Considerations

While creosote removers can aid in the management of creosote accumulation, they are not a substitute for regular mechanical chimney sweeping. These products primarily serve to loosen or modify creosote deposits, making them easier to remove through brushing. Over-reliance on chemical removers without mechanical cleaning can lead to a false sense of security and potentially mask underlying structural issues within the chimney. Safety precautions, including the use of appropriate personal protective equipment and adherence to manufacturer instructions, are essential when handling and applying creosote removers.

- Integration with Mechanical Sweeping

The most effective approach to creosote management involves a combined strategy of chemical treatment and mechanical sweeping. Chemical removers can be used to pre-treat heavily creosoted chimneys, facilitating more thorough cleaning during subsequent mechanical sweeps. Regular application of creosote removers between professional cleanings can also help to slow the rate of creosote accumulation and reduce the overall risk of chimney fires. This integrated approach optimizes chimney safety and efficiency.

The proper selection and application of creosote removers, in conjunction with regular mechanical sweeping, are integral components of comprehensive chimney maintenance programs. Understanding the limitations and safety considerations associated with these products is crucial for ensuring their effective and responsible use within the context of broader chimney sweep practices.

4. Chimney Cap

The chimney cap, as a component of comprehensive chimney maintenance, directly impacts the effectiveness and longevity of chimney sweep products and services. Functioning as a protective barrier atop the chimney flue, it prevents the intrusion of external elements that contribute to internal degradation and reduced system efficiency. The absence of a properly functioning cap directly precipitates conditions that necessitate more frequent and intensive chimney cleaning interventions.

For example, rainwater infiltration, unchecked by a cap, accelerates the deterioration of flue linings, leading to cracking and spalling. This necessitates more frequent inspections and potential repairs, increasing the demand for related products. Furthermore, animal nesting within uncapped chimneys obstructs airflow and introduces combustible materials, increasing the likelihood of chimney fires and the need for emergency cleaning services. Leaf and debris accumulation exacerbates creosote buildup, requiring more aggressive and potentially damaging cleaning techniques. Thus, the chimney cap serves as a primary line of defense, mitigating the causes that drive demand for more intensive chimney sweep services. The relationship between the absence of a cap and increased cleaning frequency is causal: the former directly influences the latter. The chimney cap ensures the longevity of chimney systems by preserving the integrity of internal components and reducing the frequency of cleaning interventions.

Therefore, the installation and maintenance of a chimney cap represent a proactive approach to chimney care, reducing the reliance on reactive cleaning and repair measures. While chimney sweep products and services remain essential for removing existing creosote and addressing structural issues, a functional cap minimizes the influx of external factors that accelerate system degradation. This underscores the importance of considering the chimney cap as an integral element within a holistic chimney maintenance strategy, one that prioritizes prevention and long-term system health.

5. Safety Gear

Safety gear constitutes a fundamental component intrinsically linked to chimney sweep activities. The occupational hazards inherent in chimney sweeping, involving exposure to particulate matter, confined spaces, and potential falls, necessitate the consistent and proper use of specialized protective equipment. This equipment mitigates the risk of respiratory illness, skin irritation, eye injury, and physical trauma, thereby ensuring the safety and well-being of chimney sweeps. The correlation between the utilization of safety gear and the reduction of occupational accidents and illnesses within the chimney sweeping profession is well-established.

The specific safety gear employed varies depending on the nature of the task and the environment in which it is performed. Typical equipment includes respirators to filter airborne particles, eye protection such as goggles or safety glasses to prevent eye irritation and injury, gloves to protect against skin contact with creosote and other irritants, and fall protection harnesses and lanyards when working at heights. Protective clothing, including coveralls and sturdy boots, further minimizes the risk of skin exposure and foot injuries. Furthermore, the selection of appropriate safety gear must consider factors such as fit, comfort, and durability to ensure consistent and effective use throughout the workday. The absence of any one of these safety elements can create a health risk.

In summary, the integration of comprehensive safety gear into chimney sweep practices is not merely a regulatory requirement but a critical ethical imperative. By prioritizing the safety and health of chimney sweeps through the provision and proper use of appropriate protective equipment, the profession can mitigate occupational hazards, enhance worker well-being, and promote a culture of safety within the industry. Continued emphasis on safety training and adherence to established safety protocols remains essential for ensuring a safe and sustainable future for chimney sweeping professionals.

6. Video Inspection

Video inspection, as a diagnostic methodology, significantly enhances the precision and effectiveness of chimney maintenance practices, directly impacting the selection and utilization of chimney sweep products. This technology enables a comprehensive internal assessment of chimney flues, identifying hidden defects and informing targeted cleaning strategies.

- Defect Identification and Product Selection

Video inspections reveal cracks, spalling, and other structural damage within chimney flues that are otherwise undetectable. This information dictates the appropriate type of chimney liner repair products, such as refractory mortars or stainless steel liners, and ensures the selection of brushes with suitable stiffness and material to prevent further damage during cleaning.

- Creosote Assessment and Treatment Strategy

Video footage allows for precise evaluation of creosote buildup, distinguishing between different stages and thicknesses. This assessment informs the selection of creosote removal products, ranging from chemical modifiers to specialized mechanical tools, and guides the intensity and frequency of cleaning procedures. Heavy creosote buildup necessitates more aggressive treatment, while minor accumulation may only require preventative measures.

- Obstruction Detection and Removal Planning

Video inspections identify obstructions such as bird nests, debris accumulation, or collapsed flue sections. This information enables the selection of appropriate removal tools, such as specialized retrieval devices or sectional rods, and guides the development of a safe and effective removal plan. Attempting to remove obstructions without prior visualization risks exacerbating the problem or causing further damage.

- Post-Cleaning Verification and Quality Control

Video inspection serves as a crucial quality control measure following chimney sweeping. It confirms the thorough removal of creosote and debris, ensuring that the cleaning process has been effective and that no residual hazards remain. This verification process reinforces the value of chimney sweep products and services by providing tangible evidence of their efficacy and contributing to overall chimney safety.

In conclusion, video inspection is not merely a supplementary service but an integral component of comprehensive chimney maintenance. By providing detailed visual information about the internal condition of chimney flues, it enables informed decision-making regarding product selection, treatment strategies, and quality control, ultimately enhancing the safety and effectiveness of chimney sweeping practices. The adoption of video inspection technology represents a significant advancement in the field, promoting proactive maintenance and minimizing the risk of chimney-related hazards.

7. Damper Seal

The integrity of the damper seal represents a pivotal factor influencing the longevity and efficiency of chimney systems, consequently affecting the utilization and effectiveness of chimney sweep products. A compromised damper seal, characterized by gaps or deterioration, permits uncontrolled airflow through the chimney flue when the fireplace is not in use. This constant airflow accelerates heat loss from the dwelling, increases energy consumption, and introduces corrosive elements into the chimney structure. The resulting degradation necessitates more frequent and intensive cleaning interventions, thereby directly increasing the demand for specialized chimney sweep products.

For example, persistent drafts caused by a faulty damper seal promote the condensation of moisture within the chimney flue. This moisture, in turn, combines with creosote deposits, forming highly corrosive compounds that attack the flue lining and accelerate creosote accumulation. The increased creosote buildup necessitates more frequent application of creosote removal products and more aggressive mechanical sweeping to maintain a safe and efficient venting system. Furthermore, the compromised seal allows for the intrusion of insects, rodents, and debris, obstructing airflow and creating fire hazards. The removal of these obstructions often requires specialized tools and cleaning techniques, further increasing the need for professional chimney sweep services. The use of sealing products specifically designed for chimney dampers, like high-temperature silicone gaskets or inflatable plugs, becomes integral in preventing these issues.

In conclusion, the proper functioning of the damper seal is inextricably linked to the overall health and efficiency of chimney systems and has real effects on product usage. Addressing damper seal deficiencies represents a proactive approach to chimney maintenance, reducing the reliance on reactive cleaning and repair measures. Integrating damper seal inspection and maintenance into routine chimney sweep services not only enhances the longevity and efficiency of the chimney system but also minimizes the demand for specialized cleaning and repair products. Recognizing this interconnectedness is crucial for implementing effective and sustainable chimney care practices.

Frequently Asked Questions about Chimney Sweep Products

The following questions and answers address common inquiries and concerns related to the selection, use, and efficacy of items employed in chimney maintenance.

Question 1: What constitutes the essential equipment required for effective chimney sweeping?

Effective chimney sweeping mandates the use of appropriately sized chimney brushes, sectional rods with secure connections, a suitable creosote removal agent, a HEPA-filtered vacuum cleaner, eye protection, respiratory protection, and drop cloths to contain debris.

Question 2: How frequently should a chimney be professionally cleaned?

Industry standards recommend that chimneys serving wood-burning appliances be inspected annually and cleaned when creosote accumulation reaches a thickness of one-eighth of an inch or greater. High-usage systems may necessitate more frequent cleaning.

Question 3: Are chemical creosote removers a substitute for mechanical chimney sweeping?

Chemical creosote removers are intended to supplement, not replace, mechanical chimney sweeping. These products can modify creosote deposits, making them easier to remove, but do not eliminate the need for physical cleaning to ensure complete removal.

Question 4: What factors should be considered when selecting a chimney brush?

Chimney brush selection must account for flue dimensions, shape, and lining material. Wire brushes are suitable for masonry chimneys, while poly brushes are recommended for metal flues to prevent scratching. The brush diameter should precisely match the flue’s internal dimensions.

Question 5: What are the potential risks associated with neglecting chimney maintenance?

Neglecting chimney maintenance can result in creosote buildup, leading to chimney fires, carbon monoxide poisoning, and reduced heating system efficiency. Structural damage to the chimney can also occur, resulting in costly repairs.

Question 6: How does a chimney cap contribute to chimney system health and longevity?

A chimney cap prevents the entry of rainwater, debris, and animals into the chimney flue, mitigating moisture damage, airflow obstructions, and potential fire hazards. It also protects the flue lining from premature deterioration, extending the lifespan of the chimney system.

Proper understanding and application of chimney maintenance protocols are essential for ensuring safe and efficient heating system operation. Consulting with a certified chimney sweep professional is recommended for personalized guidance and comprehensive service.

The following section will address the regulatory landscape governing chimney sweep practices and product standards.

In Summary

The preceding exploration underscores the critical role of items designed for chimney maintenance in ensuring structural integrity, operational efficiency, and, above all, occupant safety. Effective deployment of specialized implements and cleaning agents, guided by informed selection criteria and adherence to industry best practices, directly mitigates the risks associated with creosote accumulation, flue deterioration, and system malfunctions.

The continued development of innovative equipment and methodologies holds the potential to further enhance the safety and effectiveness of chimney maintenance practices. A sustained commitment to professional training, rigorous quality control, and proactive preventative measures remains paramount for safeguarding homes and promoting long-term sustainability within the chimney sweeping industry. Responsible ownership entails vigilance and a dedicated approach to maintenancepotentially life-saving actions dependent on utilizing proper implements.