An organization that specializes in the maintenance and cleaning of residential and commercial chimneys is a vital component of home safety. These entities provide services such as removing creosote and other debris, inspecting for structural damage, and ensuring proper ventilation. For example, a homeowner experiencing smoke backdrafts might employ such a business to diagnose and rectify the issue.

The existence of these firms provides significant benefits, mitigating the risk of chimney fires and carbon monoxide poisoning. Historically, they played a crucial role in urban environments, particularly during periods when coal was a primary fuel source. Modern counterparts continue to uphold safety standards and employ updated technologies to guarantee efficient and secure chimney operation. Regular maintenance performed by such organizations extends the lifespan of chimney systems, representing a cost-effective approach to preventative home care.

The following discussion will delve into the specific services offered, the training and certifications often held by their technicians, and the factors homeowners should consider when selecting a reliable provider.

Expert Advice on Chimney Maintenance

Maintaining a chimney in optimal condition necessitates a proactive and informed approach. The following recommendations are presented to facilitate effective chimney care, reducing the likelihood of potential hazards and maximizing operational efficiency.

Tip 1: Schedule Annual Inspections: A comprehensive inspection, conducted by qualified professionals, is essential for identifying structural weaknesses, creosote buildup, and blockages. This preventative measure allows for timely repairs and ensures safe operation.

Tip 2: Prioritize Regular Cleaning: The accumulation of creosote, a highly flammable byproduct of combustion, poses a significant fire risk. Scheduled cleanings, based on frequency of use and fuel type, are crucial for mitigating this hazard.

Tip 3: Utilize Seasoned Wood: Burning wood with a moisture content exceeding 20% results in increased creosote production. Seasoned wood, dried for a minimum of six months, burns more efficiently and reduces creosote buildup.

Tip 4: Monitor Chimney Draft: A properly functioning chimney draft is vital for venting combustion gases safely. Signs of poor draft include smoke backdrafts into the living space, indicating potential blockages or insufficient air supply.

Tip 5: Address Water Intrusion Promptly: Water damage can compromise the structural integrity of the chimney. Inspect the chimney crown, flashing, and brickwork for signs of leaks and address any issues immediately.

Tip 6: Install a Chimney Cap: A chimney cap serves multiple purposes, preventing rainwater, debris, and animals from entering the chimney, thereby protecting the flue liner and preventing obstructions.

Adhering to these guidelines will contribute significantly to the longevity and safety of the chimney system. Regular maintenance and diligent attention to potential issues are key to preventing costly repairs and ensuring the well-being of occupants.

The subsequent section will explore common chimney problems and their associated solutions, providing further insights into effective chimney management.

1. Creosote Removal

Creosote removal is intrinsically linked to the function of an enterprise specializing in chimney maintenance. Creosote, a highly combustible byproduct of incomplete combustion in wood-burning appliances, accumulates within chimney flues. This accumulation creates a significant fire hazard. A core service offering of organizations dedicated to chimney upkeep involves the systematic and thorough extraction of creosote deposits to mitigate this risk.

The methods employed for creosote removal vary based on the type and severity of the buildup. Mechanical brushing, utilizing specialized tools to scrape and dislodge creosote, is a common technique. Chemical treatments, designed to modify the structure of creosote, rendering it more easily removable, represent another approach. The effectiveness of creosote removal directly impacts the operational safety of a chimney system, influencing the likelihood of chimney fires and the potential for structural damage.

Therefore, creosote removal is not merely an ancillary task but a foundational element of a chimney maintenance operation. The competence and diligence with which this service is performed directly correlates with the overall safety and performance of residential and commercial heating systems. Regular and thorough creosote removal ensures the safe and efficient venting of combustion byproducts, minimizing the risk of hazardous events.

2. Safety Inspection

A comprehensive safety inspection forms a cornerstone of services provided by a chimney maintenance enterprise. The purpose of this inspection is to identify potential hazards and structural deficiencies that could compromise the chimney’s safe operation. This activity is essential for preventing chimney fires, carbon monoxide leaks, and other risks associated with faulty chimney systems. For instance, an inspection might reveal cracks in the flue liner, indicating a pathway for dangerous gases to escape into the living space, or detect excessive creosote buildup, a precursor to chimney fires. Neglecting this critical service can have severe consequences, as illustrated by cases where undetected structural flaws led to chimney collapses, resulting in property damage and potential injuries.

These inspections are not merely visual assessments; they frequently involve the use of specialized equipment, such as cameras, to examine the internal structure of the chimney flue. This technology allows for the detection of hidden defects, such as deteriorated mortar joints or displaced flue tiles, that would otherwise go unnoticed. Furthermore, trained technicians assess the overall draft of the chimney, ensuring it is adequate for safely venting combustion gases. The inspection process typically adheres to established industry standards and local building codes, providing homeowners with assurance that their chimney system meets safety requirements. Proper execution of a safety inspection not only identifies existing problems but also helps to anticipate future issues, allowing for proactive maintenance and repairs.

In summary, the safety inspection provided by a chimney maintenance company is paramount for ensuring the continued safe operation of a chimney system. It serves as a critical preventative measure, identifying potential hazards before they escalate into serious problems. Through thorough assessments and the use of specialized equipment, these inspections protect property and, more importantly, safeguard the well-being of occupants. The insights gained allow for informed decisions regarding maintenance and repairs, contributing to the long-term functionality and safety of the chimney system.

3. Code Compliance

Adherence to relevant building codes and regulations is inextricably linked to the operational framework of a chimney maintenance enterprise. These codes, established by local, state, and national authorities, dictate the standards for chimney construction, maintenance, and safety. A chimney maintenance company must possess a comprehensive understanding of these codes to ensure its services align with legal requirements. Failure to comply with applicable codes can result in fines, legal liabilities, and, more critically, increased risks of chimney fires or carbon monoxide poisoning.

The chimney sweep company, by ensuring code compliance, mitigates risk by verifying structural integrity, proper clearances from combustible materials, and adequate ventilation. Example: a company performing an inspection identifying a missing firestop between a chimney and a wooden floor. Code mandates the presence of a firestop to prevent the spread of fire. Rectifying this deficiency demonstrates practical code compliance, protecting the building and its occupants. Similarly, regulations govern chimney height above the roofline to ensure adequate draft; a company identifying and correcting a height deficiency would be fulfilling its role in code compliance. Code requirements are not static; they evolve to reflect advancements in building science and safety practices. The company must stay abreast of these changes through ongoing training and certification to maintain code compliance.

In summary, code compliance is not a mere formality; it is a critical aspect of chimney maintenance. The safety and legality of a chimney system are directly dependent on adherence to these regulations. Enterprises specializing in chimney maintenance are tasked with ensuring that systems meet these requirements, protecting properties and lives. While challenging to maintain up-to-date knowledge of evolving codes, the consequences of non-compliance necessitate a commitment to ongoing education and rigorous inspection practices.

4. Specialized Equipment

The effectiveness and safety of a chimney maintenance organization’s operations hinge significantly on the utilization of specialized equipment. These tools are not merely conveniences; they are essential for accurate inspection, thorough cleaning, and safe execution of repairs within potentially hazardous environments.

- Chimney Cameras and Scanners

These devices facilitate internal visual inspections of chimney flues, enabling technicians to identify cracks, obstructions, and other structural defects that would be impossible to detect through conventional methods. For instance, a miniature camera lowered into a chimney can reveal deteriorated flue liners, necessitating repair or replacement. The ability to visualize the interior structure is crucial for accurate diagnosis and targeted maintenance.

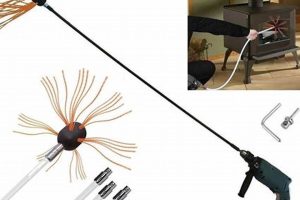

- Power Sweeping Systems

Power sweeping systems employ rotating brushes and flexible rods to effectively remove creosote buildup from chimney walls. These systems are more efficient and thorough than traditional hand-operated brushes, particularly in complex chimney configurations. Consider the case of a chimney with multiple offsets; a power sweeping system can navigate these bends, ensuring complete creosote removal throughout the entire flue.

- HEPA Vacuum Systems

Chimney cleaning generates significant dust and debris, posing a health hazard to both technicians and occupants. High-Efficiency Particulate Air (HEPA) vacuum systems capture these particles, preventing their release into the surrounding environment. A HEPA vacuum system minimizes the risk of respiratory irritation and ensures a cleaner, safer working environment during chimney maintenance activities.

- Gas Analyzers

Following chimney repairs or modifications, gas analyzers are used to verify proper draft and ensure the safe venting of combustion gases. These devices measure the concentration of carbon monoxide and other hazardous gases, confirming that the chimney is functioning as intended. Gas analyzers are particularly crucial after installing new heating appliances or making significant alterations to a chimney system.

The strategic deployment of specialized equipment not only enhances the quality of services offered by a chimney sweep entity but also directly impacts safety and efficiency. From diagnostic tools that reveal hidden defects to cleaning systems that ensure thorough creosote removal, these technologies are indispensable for maintaining functional and safe chimney systems.

5. Regional Demand

Regional demand exerts a significant influence on the operational dynamics and service offerings of an enterprise specializing in chimney maintenance. The geographical location and its attendant climatic conditions, fuel usage patterns, and housing characteristics create varying levels of demand for chimney-related services.

- Climate and Heating Season Length

Regions experiencing prolonged cold seasons typically exhibit higher demand for chimney maintenance services. Increased usage of wood-burning stoves and fireplaces leads to greater creosote accumulation, necessitating more frequent inspections and cleanings. For example, in northern states with extended winters, homeowners are more likely to utilize their fireplaces regularly, thereby driving demand for professional chimney services.

- Fuel Type Prevalence

The primary fuel source used for heating within a region directly impacts the type and frequency of chimney maintenance required. Areas where wood is a prevalent fuel source will experience a greater need for creosote removal services compared to regions where gas or electric heating is dominant. Coal-burning areas present unique challenges due to the heavier sooting and potential for sulfurous deposits, necessitating specialized cleaning techniques and equipment.

- Housing Stock Characteristics

The age and type of housing stock within a region influence the demand for chimney services. Older homes, particularly those with masonry chimneys, are more susceptible to structural damage and require more frequent inspections and repairs. Furthermore, the prevalence of multi-story buildings and attached dwellings in urban areas creates specific challenges related to chimney access and maintenance, impacting the operational logistics of chimney maintenance firms.

- Local Regulations and Awareness

Stringent local regulations regarding chimney safety and homeowner awareness of fire hazards can significantly boost demand. Regions with proactive fire safety education programs and strict enforcement of building codes tend to have higher rates of chimney inspections and cleanings. This heightened awareness and regulatory oversight create a more safety-conscious consumer base, driving demand for professional chimney services.

The interplay of these regional factors shapes the market landscape for chimney maintenance organizations. The service offerings, pricing strategies, and marketing efforts of these enterprises must be tailored to the specific needs and characteristics of the regions they serve. Ultimately, understanding and responding to regional demand is critical for the sustainability and success of a chimney maintenance enterprise.

Frequently Asked Questions

The following addresses common inquiries regarding chimney maintenance, safety, and operational procedures. The information provided is intended to clarify misconceptions and promote informed decision-making.

Question 1: How frequently should a chimney undergo professional cleaning?

Chimney cleaning frequency depends primarily on the type of fuel burned and the frequency of appliance usage. It is generally recommended that a chimney serving a wood-burning appliance undergo inspection annually and cleaning when creosote accumulation exceeds one-eighth of an inch.

Question 2: What are the primary indicators of a potential chimney fire?

Audible rumbling or popping sounds emanating from the chimney, dense smoke emanating from the chimney top, and a strong, acrid odor are potential indicators of a chimney fire. Immediate evacuation and contacting emergency services is crucial if these signs are observed.

Question 3: Is it possible to safely perform chimney cleaning without professional assistance?

While DIY chimney cleaning is feasible, it is not recommended for individuals lacking the necessary equipment, knowledge, and experience. Improper cleaning can damage the flue liner, increase the risk of chimney fires, and potentially lead to carbon monoxide poisoning.

Question 4: What role does a chimney cap play in chimney safety and maintenance?

A chimney cap serves multiple functions. It prevents rainwater, debris, and animals from entering the chimney flue, protecting the chimney structure and preventing obstructions. A spark arrestor component also reduces the risk of sparks escaping and igniting nearby combustible materials.

Question 5: What constitutes a Level 1, Level 2, and Level 3 chimney inspection?

A Level 1 inspection is a visual examination of readily accessible chimney components. A Level 2 inspection includes a video scan of the flue and is required upon the sale or transfer of a property, or after an operational malfunction or external event. A Level 3 inspection involves the removal of chimney components to examine concealed areas, typically performed when a Level 1 or 2 inspection reveals a potential hazard.

Question 6: Are there specific regulations governing the disposal of creosote removed during chimney cleaning?

Local regulations often govern the disposal of creosote, which is considered a hazardous material due to its flammability and potential environmental impact. Adherence to these regulations is essential to avoid fines and ensure responsible waste management. Contact local waste management services for specific guidance.

Proactive maintenance and adherence to safety guidelines are paramount in mitigating the risks associated with chimney systems. Informed decisions and regular professional inspections contribute significantly to the safety and longevity of residential and commercial chimneys.

The following section will explore strategies for selecting a reputable and qualified chimney maintenance enterprise.

Conclusion

This exploration has illuminated critical facets of an enterprise specializing in chimney maintenance. From the fundamental imperative of creosote removal to the necessity of code compliance and the strategic deployment of specialized equipment, the multifaceted nature of these organizations is evident. Regional demand, shaped by climatic conditions and fuel usage patterns, further defines the operational landscape.

The significance of employing qualified professionals for chimney maintenance cannot be overstated. The integrity of a chimney system directly impacts the safety and well-being of building occupants. Prioritizing regular inspections, adhering to established safety guidelines, and engaging reputable service providers are essential for safeguarding property and preventing potential hazards. Continued diligence and informed decision-making are paramount in upholding the longevity and safe operation of these vital components of residential and commercial structures.