The occupation in question involves the maintenance of structures designed to vent combustion byproducts from residential and commercial properties located in littoral regions. Functionally, it addresses the removal of creosote, soot, and other debris that accumulate within these structures, ensuring proper ventilation and mitigating the risk of chimney fires. For example, a dwelling situated near the ocean might require this service to maintain a safe and efficient heating system.

Regular upkeep of these systems offers several advantages. It significantly reduces the potential for dangerous and costly fires, improves the efficiency of heating appliances, and helps to maintain indoor air quality by preventing backdrafting of harmful gases. Historically, this trade was crucial in urban centers and rural communities alike, providing a vital service for preserving property and safeguarding lives.

The following sections will elaborate on the specific challenges presented by maritime environments, the techniques employed in this specialized field, and the importance of professional certification in ensuring quality service and adherence to safety standards. These factors contribute to the overall effectiveness and longevity of these critical home components.

Coastal Chimney Maintenance

The marine environment presents unique challenges to chimney systems. Proactive maintenance is critical for safety and efficiency. Neglecting these considerations can lead to accelerated deterioration and increased risk.

Tip 1: Schedule Annual Inspections: A qualified professional should conduct a thorough examination of the chimney system at least once a year. This includes checking for cracks, obstructions, and signs of deterioration, which are exacerbated by coastal conditions.

Tip 2: Address Salt Air Corrosion: Salt air accelerates corrosion. The application of protective coatings specifically designed for marine environments can extend the lifespan of metal components, such as chimney caps and liners.

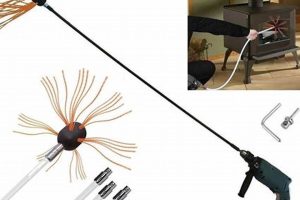

Tip 3: Remove Creosote Buildup Regularly: Creosote accumulation increases the risk of chimney fires. Regular sweeping, performed by a trained technician, removes this flammable substance and ensures proper ventilation.

Tip 4: Monitor for Water Intrusion: Water damage, common in coastal areas, can compromise the structural integrity of the chimney. Inspect for leaks and address them promptly to prevent further deterioration. Consider installing a chimney cap to minimize water entry.

Tip 5: Utilize Stainless Steel Components: When replacing chimney liners or other parts, opt for stainless steel materials. These are more resistant to corrosion compared to standard materials, especially in salty air.

Tip 6: Ensure Proper Ventilation: Adequate airflow is essential for efficient combustion and prevents the buildup of harmful gases. Ensure that the chimney flue is appropriately sized for the heating appliance.

Tip 7: Trim Overhanging Vegetation: Branches and foliage near the chimney can create fire hazards and impede airflow. Regularly trim vegetation to maintain a safe distance from the chimney structure.

Adhering to these guidelines will contribute to a safer and more efficient heating system, specifically tailored to the demands of a coastal environment. Consistent attention to these details ensures longevity and mitigates potential hazards.

The next section will discuss the importance of selecting a qualified service provider and the factors to consider when evaluating credentials and experience.

1. Saltwater Corrosion Mitigation

In coastal regions, chimney systems face accelerated degradation due to the pervasive presence of saltwater. Effective mitigation strategies are essential for preserving structural integrity and operational safety. These efforts directly impact the role and responsibilities of chimney professionals operating in these environments.

- Material Selection and Application

The selection of corrosion-resistant materials is paramount in chimney construction and repair. Stainless steel, particularly marine-grade alloys, offers enhanced protection against the corrosive effects of salt. Furthermore, protective coatings, specifically formulated to withstand saltwater exposure, can extend the lifespan of chimney components. An example would be using a ceramic-based coating on a chimney cap to prevent rust from forming due to constant salt spray. Proper application by trained technicians ensures optimal adherence and effectiveness.

- Sacrificial Anodes

Sacrificial anodes can be strategically placed within the chimney system to redirect corrosive activity away from critical structural elements. These anodes, typically composed of metals more reactive than the surrounding materials, corrode preferentially, thereby protecting the primary components. An analogous situation exists in shipbuilding, where these anodes protect the hull from corrosion. Regular inspection and replacement of sacrificial anodes are crucial for maintaining their protective function.

- Ventilation and Moisture Control

Proper ventilation within the chimney system minimizes the accumulation of moisture, which exacerbates saltwater corrosion. Ensuring adequate airflow through the flue reduces humidity levels and inhibits the formation of corrosive compounds. Addressing any sources of water intrusion, such as leaks in the chimney crown or flashing, is also critical. Ignoring these issues can lead to accelerated rusting and structural weakening.

- Regular Inspection and Maintenance Protocols

Comprehensive inspection and maintenance protocols are vital for identifying and addressing early signs of corrosion. Professionals trained in coastal chimney maintenance can assess the condition of chimney components, detect corrosion hotspots, and implement appropriate remedial measures. These measures may include cleaning to remove salt deposits, applying protective coatings, or replacing severely corroded sections. The frequency of inspections should be adjusted based on the severity of the coastal environment and the materials used in the chimney’s construction.

The implementation of these saltwater corrosion mitigation strategies is directly linked to the expertise and services provided by qualified professionals operating in coastal regions. Their ability to assess, diagnose, and address corrosion-related issues ensures the longevity, safety, and efficiency of chimney systems exposed to this harsh environment. Regular maintenance and proactive protection are the keys to preventing costly repairs and ensuring the safe operation of chimney systems in coastal homes.

2. Specialized Cleaning Techniques for Coastal Chimneys

The maintenance of chimney systems in coastal environments necessitates specialized cleaning techniques that address the unique challenges posed by salt air, humidity, and specific combustion byproducts. These techniques differ significantly from those employed in inland regions due to the accelerated corrosion and deposition rates observed in littoral climates.

- Salt Deposit Removal

Salt aerosol deposition on internal chimney surfaces leads to the formation of highly corrosive salt crystals. Standard sweeping methods are often insufficient for removing these deposits effectively. Specialized cleaning techniques involve the use of chemical treatments specifically designed to dissolve salt crystals without damaging the chimney liner. For example, a neutral pH solution may be applied to loosen salt buildup before mechanical removal. This prevents the abrasive action of dry brushing on weakened materials, extending the life of the system.

- Creosote Modification and Removal in High-Humidity Environments

Coastal humidity affects the composition and adhesion of creosote, the primary combustible deposit in wood-burning chimney systems. High moisture content can create a glazed, tar-like creosote that is difficult to remove with conventional brushes. Specialized cleaning techniques include the application of creosote modification agents. These agents alter the chemical structure of the creosote, making it more brittle and easier to remove with rotary cleaning tools. An example is the use of enzyme-based treatments that break down the complex hydrocarbons within the creosote, reducing its adherence to the flue.

- Corrosion-Resistant Tooling and Materials

The use of appropriate tools and materials is paramount in coastal chimney cleaning. Standard steel brushes can accelerate corrosion on metal chimney components. Specialized cleaning techniques involve the use of stainless steel or nylon brushes that minimize galvanic corrosion. Furthermore, corrosion-resistant lubricants and cleaning agents are employed to protect metal surfaces from further degradation. For instance, applying a thin layer of silicone-based lubricant to the flue after cleaning can provide a protective barrier against moisture and salt.

- Inspection and Documentation of Corrosion Damage

Before and after cleaning, a thorough inspection of the chimney system is essential. Specialized cleaning techniques include the use of video inspection equipment to identify and document corrosion damage that may not be visible to the naked eye. This allows for the early detection of structural weaknesses and facilitates informed decisions regarding repair or replacement. An example includes using a chimney camera to assess the condition of a stainless steel liner for pitting or perforation due to corrosion, enabling a targeted approach to maintenance.

These specialized cleaning techniques, when implemented by trained professionals, are critical for ensuring the safe and efficient operation of chimney systems in coastal regions. Their application addresses the unique challenges posed by these environments, mitigating the risks associated with corrosion, creosote buildup, and structural deterioration. Neglecting these considerations can lead to premature system failure and increased fire hazards.

3. Weather-resistant materials

The selection and utilization of weather-resistant materials are paramount to the longevity and safety of chimney systems in coastal environments. Given the persistent exposure to saltwater, high humidity, and strong winds, conventional building materials often exhibit accelerated degradation. This necessitates a focused approach to material selection and maintenance within the domain of the coastal chimney sweep.

- Stainless Steel Alloys

Certain stainless steel alloys, particularly those with increased chromium and molybdenum content, demonstrate superior resistance to pitting and crevice corrosion in chloride-rich environments. These alloys are frequently employed in the fabrication of chimney liners, caps, and chase covers, providing a robust barrier against the corrosive effects of salt spray. The increased initial cost is often offset by a significantly extended service life compared to traditional galvanized steel, reducing the frequency of costly replacements.

- Protective Coatings and Sealants

The application of specialized coatings and sealants provides an additional layer of protection against moisture intrusion and salt deposition. These coatings, often composed of acrylic polymers or elastomeric compounds, create a water-repellent barrier that prevents water from penetrating the brickwork or masonry. Sealants are utilized to prevent water infiltration at joints and connections, mitigating the risk of freeze-thaw damage during colder months. Regular reapplication of these protective measures is crucial for maintaining their effectiveness.

- Fiber Cement and Composite Materials

For chimney chase construction, fiber cement and composite materials offer a durable and weather-resistant alternative to traditional wood framing. These materials are impervious to rot, insect infestation, and moisture damage, making them well-suited for coastal environments. Their dimensional stability minimizes the risk of warping and cracking, ensuring a tight seal against the elements. Furthermore, fiber cement siding can be painted or stained to match the aesthetic of the surrounding structure.

- Water-Repellent Brick and Mortar

The use of water-repellent brick and mortar formulations minimizes water absorption, thereby reducing the risk of spalling and cracking. These materials contain hydrophobic additives that repel water at the surface, preventing it from penetrating the brickwork. In coastal areas, where wind-driven rain is common, the use of water-repellent brick and mortar is essential for preserving the structural integrity of the chimney. Regular inspection and maintenance, including the reapplication of water-repellent treatments, are critical for long-term performance.

The proper selection and application of weather-resistant materials, as an integral part of coastal chimney sweep services, directly contribute to the enhanced safety, longevity, and aesthetic appeal of chimney systems in challenging marine environments. These materials, when correctly implemented, minimize the need for frequent repairs, reduce the risk of fire hazards, and preserve the structural integrity of coastal properties.

4. Annual professional inspections

Annual professional inspections are a critical component of responsible chimney maintenance, particularly within the demanding context of the coastal chimney sweep trade. The marine environment presents unique challenges that necessitate regular and thorough assessments conducted by qualified professionals.

- Early Detection of Corrosion and Deterioration

Coastal environments accelerate corrosion and material degradation. Annual inspections enable the early detection of rust, spalling, and other forms of deterioration that might otherwise go unnoticed. For instance, a professional might identify hairline cracks in the chimney crown, a precursor to more significant water damage. Early intervention prevents costly repairs and maintains structural integrity.

- Identification of Salt Accumulation and Creosote Buildup

Salt aerosols and creosote accumulation are significant concerns in coastal chimneys. Professionals assess the extent of salt deposition on interior surfaces, which can lead to corrosion. Furthermore, they evaluate creosote buildup, a fire hazard that is exacerbated by coastal humidity. Regular inspections allow for timely cleaning and removal of these deposits, mitigating potential risks. An inspection might reveal a layer of glazed creosote, requiring specialized removal techniques.

- Assessment of Ventilation and Flue Integrity

Proper ventilation is essential for efficient combustion and the safe venting of exhaust gases. Annual inspections include assessing the flue’s integrity, identifying obstructions, and ensuring proper sizing. Coastal winds can create downdrafts, impacting ventilation. Professionals verify that the chimney cap is functioning correctly and that the flue is free from debris. Blocked flues increase the risk of carbon monoxide poisoning.

- Verification of Compliance with Safety Standards

Building codes and safety standards regulate chimney construction and maintenance. Annual inspections ensure that the chimney system complies with current regulations. Professionals assess clearances to combustibles, verify proper flue liner installation, and confirm that the chimney is structurally sound. Compliance minimizes fire hazards and ensures homeowner safety. An inspection might reveal non-compliant construction, requiring corrective action.

The facets outlined above highlight the integral role of annual professional inspections in maintaining safe and efficient chimney systems in coastal regions. These inspections provide a proactive approach to identify and address potential problems before they escalate into significant hazards, thereby safeguarding property and ensuring the well-being of occupants. Regular assessments by qualified professionals are a necessity, not a luxury, for coastal homeowners.

5. Creosote Removal Frequency

The frequency of creosote removal in chimney systems serviced by a coastal chimney sweep is a critical safety consideration, significantly influenced by the unique environmental factors prevalent in maritime regions. These factors necessitate a more vigilant and potentially more frequent approach to creosote management than in inland areas.

- Accelerated Creosote Formation Due to Humidity

Coastal regions often experience higher humidity levels. This increased moisture content can affect the combustion process within a chimney, leading to the formation of a more viscous and adherent type of creosote. Denser creosote accumulation increases the risk of chimney fires. A chimney serving a seaside cottage, for instance, might exhibit a faster rate of creosote buildup compared to an identical system located inland, necessitating more frequent sweeping.

- Impact of Salt Air on Combustion Efficiency

Salt aerosols present in coastal air can interfere with the efficient combustion of wood or other fuels. This incomplete combustion results in increased particulate matter, which contributes to the accumulation of creosote within the chimney flue. For example, a wood-burning stove in a coastal home might produce more smoke and soot, leading to a faster creosote buildup rate. This requires a more diligent approach to creosote monitoring and removal.

- Material Degradation and Creosote Adhesion

The corrosive effects of salt air can degrade the materials used in chimney construction, such as metal liners and masonry. This degradation creates rougher surfaces, providing more adhesion points for creosote to accumulate. A corroded flue liner in a coastal chimney can trap creosote more readily than a smooth, intact liner, increasing the risk of fire. Consequently, more frequent sweeping becomes necessary to mitigate this hazard.

- Fuel Type and Burning Habits

While not exclusive to coastal regions, the type of fuel burned and the burning habits of the homeowner significantly influence creosote accumulation. The use of unseasoned wood, for example, increases the moisture content and leads to more creosote production, regardless of location. However, the combination of poor burning practices and the exacerbating factors of a coastal environment necessitate an even greater emphasis on regular creosote removal. For instance, consistently burning damp wood in a coastal home’s fireplace will result in a rapid creosote buildup, demanding frequent professional intervention.

The interplay between environmental factors, material condition, and user practices underscores the critical importance of tailored creosote removal schedules for coastal chimney systems. Coastal chimney sweeps must assess these variables to determine an appropriate cleaning frequency, prioritizing safety and minimizing the risk of chimney fires in these uniquely challenging environments.

Frequently Asked Questions Regarding Coastal Chimney Maintenance

The following section addresses common inquiries pertaining to the care and upkeep of chimney systems in coastal environments. These questions are answered with the intention of providing clear and accurate information for homeowners and property managers.

Question 1: What distinguishes chimney maintenance in coastal areas from that in inland regions?

Coastal areas present unique challenges due to salt air, high humidity, and strong winds. These conditions accelerate corrosion, promote creosote buildup, and increase the risk of structural damage. Standard chimney maintenance practices may be insufficient to address these issues effectively.

Question 2: How frequently should a chimney be inspected in a coastal environment?

Annual inspections are highly recommended for chimneys in coastal areas. The increased rate of deterioration necessitates more frequent assessments to identify and address potential problems before they escalate into costly repairs or safety hazards.

Question 3: What materials are best suited for chimney construction and repair in coastal zones?

Stainless steel alloys, particularly those with high chromium and molybdenum content, offer superior resistance to corrosion. Protective coatings, water-repellent brick, and fiber cement materials are also recommended for their durability and resistance to saltwater damage.

Question 4: How does salt air affect creosote accumulation in coastal chimneys?

Salt aerosols can interfere with the efficient combustion of fuel, leading to increased particulate matter and creosote formation. Additionally, salt deposits on chimney surfaces create a porous texture, which promotes creosote adhesion. More frequent creosote removal may be necessary.

Question 5: What are the warning signs of chimney damage in a coastal environment?

Warning signs include visible rust or corrosion, spalling brickwork, water stains, crumbling mortar, and unusual odors emanating from the chimney. These indicators suggest underlying problems that require prompt attention from a qualified professional.

Question 6: Why is it essential to hire a certified coastal chimney sweep for maintenance and repairs?

Certified coastal chimney sweeps possess the specialized knowledge and experience necessary to address the unique challenges of maintaining chimney systems in marine environments. They are trained to identify corrosion patterns, implement appropriate cleaning techniques, and select weather-resistant materials, ensuring the safety and longevity of the chimney.

In summation, diligent chimney maintenance is crucial for coastal properties due to accelerated deterioration factors. Proactive measures are recommended to protect property and ensure safety.

The subsequent section will provide resources for locating certified professionals specializing in this domain.

Conclusion

The preceding discussion has elucidated the complexities inherent in maintaining chimney systems within coastal environments. The effects of salt air, humidity, and frequent storms necessitate specialized knowledge and practices that differ significantly from standard chimney maintenance. Regular inspections, appropriate material selection, and diligent creosote removal are crucial for ensuring the safety and longevity of these systems.

Given the potential for significant property damage and safety hazards arising from neglected chimney maintenance in coastal regions, engaging the services of a qualified professional is strongly advised. The expertise of a coastal chimney sweep is paramount in mitigating risks and preserving the integrity of these essential structural components. Homeowners are encouraged to prioritize preventative measures and seek certified professionals to safeguard their properties and well-being.