These devices are systems designed to protect and preserve chimney structures from deterioration caused by weather, flue gas condensation, and other damaging elements. They typically incorporate features such as chimney caps, crown sealants, and flue liners to provide a barrier against moisture and corrosive substances. For instance, a properly installed cap prevents rainwater from entering the flue, while a sealant safeguards the vulnerable chimney crown.

The advantages of such protective measures are manifold, encompassing extended chimney lifespan, improved heating efficiency, and enhanced home safety. Historically, the focus on chimney preservation has grown with increased awareness of the long-term costs associated with neglecting chimney maintenance. By preventing water damage and flue gas erosion, these systems mitigate the need for costly repairs or complete chimney rebuilds. Moreover, a well-maintained chimney contributes to proper draft and venting, optimizing heating appliance performance and reducing the risk of carbon monoxide exposure.

The subsequent sections will delve into the specific components of these protective systems, including chimney caps, crown repair materials, and flue lining options, examining their respective functionalities and installation considerations. This exploration will provide a detailed understanding of how each element contributes to overall chimney health and longevity.

Chimney Preservation Strategies

Effective chimney maintenance is crucial for structural integrity and operational safety. The following strategies outline proactive measures to ensure long-term chimney health.

Tip 1: Regular Inspection: Conduct annual professional chimney inspections. Early detection of cracks, deterioration, or blockages enables timely repairs and prevents extensive damage. A qualified technician can identify potential hazards and recommend appropriate solutions.

Tip 2: Install a Chimney Cap: A chimney cap is a fundamental safeguard. It prevents rainwater, debris, and animals from entering the flue. Select a cap constructed from durable materials like stainless steel for optimal protection and longevity.

Tip 3: Address Crown Damage Promptly: The chimney crown is particularly vulnerable to weathering. Inspect for cracks and deterioration. Apply a high-quality crown sealant to prevent water penetration and structural degradation. Rebuild the crown if damage is extensive.

Tip 4: Consider Flue Lining: A properly installed flue liner protects the chimney from corrosive flue gases. Ensure the liner is appropriately sized for the heating appliance. Replace damaged or deteriorated liners to maintain structural integrity and prevent carbon monoxide leakage.

Tip 5: Manage Moisture: Control moisture infiltration into the chimney system. Ensure proper drainage around the base of the chimney to prevent water from wicking up into the structure. Trim vegetation that may retain moisture against the chimney.

Tip 6: Burn Seasoned Wood: Burning seasoned wood reduces creosote buildup in the flue. Creosote is a flammable byproduct of incomplete combustion. Use well-seasoned wood with a moisture content below 20% to minimize creosote accumulation and reduce the risk of chimney fires.

Tip 7: Professional Cleaning: Schedule regular professional chimney cleaning to remove creosote and other deposits. Frequency depends on heating appliance usage, but annual cleaning is generally recommended to maintain safety and efficiency.

Adopting these preservation strategies will significantly extend chimney lifespan, improve heating system efficiency, and mitigate potential safety hazards.

The subsequent section will address common issues and frequently asked questions related to chimney upkeep, providing further guidance for homeowners.

1. Prevention of Water Ingress

Water intrusion poses a significant threat to chimney structures, leading to accelerated deterioration and compromised functionality. Employing preventive measures constitutes a core aspect of safeguarding chimney integrity and minimizing long-term maintenance costs. Protecting against water ingress directly contributes to the overall effectiveness.

- Chimney Cap Installation

The installation of a properly sized and secured chimney cap is a primary defense against precipitation. The cap shields the flue opening, preventing rainwater, snow, and debris from entering the chimney. This barrier significantly reduces the amount of moisture that penetrates the system, mitigating water damage. Example: Stainless steel chimney caps offer enhanced durability and resistance to corrosion, providing long-term protection. Its prevention reduces wear and tear.

- Crown Sealing and Repair

The chimney crown, typically constructed of concrete or mortar, is particularly vulnerable to water damage. Cracks and deterioration in the crown allow water to seep into the chimney structure. Applying a high-quality crown sealant or undertaking crown repairs addresses these vulnerabilities, creating a waterproof barrier that protects the underlying brickwork or masonry. Regular inspection and prompt repair of the crown are essential components of effective prevention. Example: Using a flexible sealant prevents water from expanding after freezing.

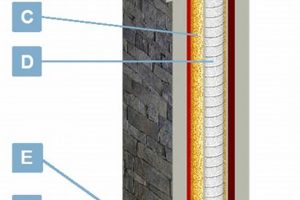

- Flue Liner Protection

A properly installed flue liner safeguards the chimney from the corrosive effects of flue gases, which often contain moisture. Protecting the liner from water intrusion is crucial to preventing deterioration and maintaining its integrity. Maintaining the waterproof integrity minimizes flue gas condensation and subsequent acid damage. Example: A stainless steel liner resistant to water will not wear over a long period of time.

- Water Repellent Application

The application of a breathable water repellent to the exterior of the chimney can provide an additional layer of protection against moisture absorption. These repellents create a hydrophobic barrier that prevents water from penetrating the brickwork or masonry while allowing water vapor to escape. This helps to reduce the risk of freeze-thaw damage and other water-related issues. Example: Use a breathable water repellent to protect but allow to vent.

The consistent implementation of these preventive measures is paramount in maintaining chimney integrity and minimizing the detrimental effects of water ingress. By proactively addressing potential vulnerabilities, homeowners can significantly extend the lifespan of their chimneys and avoid costly repairs.

2. Creosote Buildup Mitigation

Creosote, a byproduct of incomplete combustion of wood, accumulates within chimney flues. This accumulation poses a significant fire hazard. Mitigation of creosote buildup is intrinsically linked to chimney longevity and safety, forming a critical aspect of comprehensive preservation. Inadequate mitigation increases the risk of chimney fires, potentially leading to structural damage and property loss. Chimney systems that actively address creosote formation and removal are thus inherently more effective and reliable.

Effective mitigation strategies include burning seasoned wood, ensuring adequate air supply to the fire, and implementing regular professional chimney cleaning. Seasoned wood burns more completely, reducing creosote production. Sufficient air promotes efficient combustion, minimizing unburned particles. Regular cleaning removes accumulated creosote before it reaches dangerous levels. Example: A chimney fire resulting from neglected creosote buildup can compromise the structural integrity, necessitating extensive repairs. Conversely, a homeowner who utilizes seasoned wood and schedules annual chimney sweeps significantly reduces this risk, extending the chimney’s lifespan and maintaining safety. A comprehensive protection plan always considers mitigation.

Understanding the causes and consequences of creosote buildup, combined with proactive mitigation measures, is crucial for responsible chimney ownership. By prioritizing creosote management, homeowners contribute directly to the preservation, minimizing fire hazards and ensuring the continued functionality. The connection between these factors underscores the importance of a holistic approach to chimney maintenance, one that incorporates both preventative and reactive measures. This approach will increase its longevity as time goes on.

3. Structural Component Reinforcement

Structural reinforcement plays a critical role in preserving chimney integrity and extending service life. Integrating reinforcement techniques within a comprehensive maintenance strategy contributes significantly to preventing premature failure and mitigating potential safety hazards. Such measures are paramount in ensuring the long-term stability and functionality of chimney systems.

- Flue Liner Installation and Repair

Flue liners protect the chimney structure from corrosive flue gases and high temperatures. Reinforcing the flue with a properly sized and installed liner prevents deterioration of the surrounding masonry. Repairs to existing liners address cracks or damage, restoring the flue’s protective function. Example: Installing a stainless steel liner in an older chimney provides a durable, corrosion-resistant barrier against flue gas damage, safeguarding the chimney’s structural integrity. Preventing this damage improves it’s long term viability.

- Chimney Crown Repair and Reconstruction

The chimney crown, located at the top of the chimney, is susceptible to weather-related damage. Reinforcing the crown with a sealant or undertaking a complete reconstruction prevents water penetration, which can lead to freeze-thaw damage and structural weakening. Example: Applying a flexible, waterproof sealant to cracks in a chimney crown prevents further water intrusion and protects the underlying masonry from deterioration. The importance of the structural component should not be underestimated.

- Masonry Repointing and Repair

Over time, mortar joints between bricks or stones can deteriorate, compromising the structural integrity of the chimney. Repointing involves removing deteriorated mortar and replacing it with fresh mortar, restoring the chimney’s strength and stability. Masonry repair addresses damaged or missing bricks, further reinforcing the chimney structure. Example: Repointing deteriorated mortar joints prevents water infiltration and maintains the chimney’s load-bearing capacity, preserving its structural soundness. This component adds both structural and aesthetic value.

- Chimney Bracing and Support

In cases where a chimney exhibits significant structural instability, bracing or additional support may be necessary. This can involve installing steel supports or reinforcing the chimney with external bracing to prevent collapse. Example: A tall, freestanding chimney that is leaning due to foundation settlement may require steel bracing to stabilize it and prevent further movement, ensuring the safety of the structure. The installation should be handled by a qualified technician.

These structural reinforcement measures, when implemented proactively, contribute significantly to prolonging the lifespan, preventing costly repairs, and ensuring the continued safe operation. These measures work together to ensure maximum possible protection.

4. Proper Ventilation Maintenance

Proper ventilation maintenance directly influences chimney performance and longevity. Restricted airflow within a chimney flue impedes efficient combustion gas removal, leading to creosote accumulation and potential carbon monoxide backdrafts into the living space. Such compromised ventilation accelerates deterioration of chimney components, diminishing structural integrity. Ventilation maintenance is thus integral to a comprehensive system designed to preserve chimney health. For example, a chimney obstructed by debris prevents proper draft, causing smoke and harmful gases to vent improperly. Addressing this obstruction restores airflow, reducing the risk of fire and carbon monoxide poisoning.

The relationship between ventilation and preservation manifests in various practical applications. Regular chimney inspections identify blockages caused by animal nests, fallen debris, or creosote buildup. Chimney sweeps remove these obstructions, ensuring unimpeded airflow. Proper sizing of the flue liner relative to the connected appliance optimizes draft and minimizes condensation, further enhancing ventilation. The installation of a chimney cap not only prevents water intrusion but also incorporates mesh screening to deter animal entry, maintaining clear ventilation pathways. Consistent attention to ventilation upkeep minimizes the strain on chimney materials, reducing wear and tear.

In summary, consistent maintenance of proper ventilation is paramount. Addressing ventilation concerns contributes directly to improved safety, extended chimney lifespan, and enhanced heating system efficiency. Neglecting ventilation not only compromises chimney performance but also poses significant risks to occupants. Consequently, integrating ventilation upkeep within a broader protection strategy is essential for responsible homeownership.

5. Material Degradation Resistance

Material degradation resistance is a critical factor influencing the longevity and effectiveness of chimney protection systems. The ability of chimney components to withstand the harsh conditions associated with flue gases, weather exposure, and thermal stress directly impacts the overall lifespan and performance of these systems. Selection of durable, resistant materials is essential for reliable chimney preservation.

- Corrosion Resistance

Flue gases contain corrosive compounds that can attack metal and masonry chimney components. Materials with inherent corrosion resistance, such as stainless steel for flue liners and caps, provide extended protection against degradation. Example: Using a 316L stainless steel liner, which has higher molybdenum content, in a chimney venting a high-efficiency appliance reduces corrosion from acidic condensate compared to using standard galvanized steel. The corrosive properties need to be considered.

- Thermal Stability

Chimneys experience significant temperature fluctuations during heating cycles. Materials that exhibit good thermal stability resist cracking, warping, and other forms of damage caused by repeated expansion and contraction. Example: Refractory mortars used in chimney construction maintain their structural integrity at high temperatures, preventing gaps from forming in the masonry and allowing flue gases to escape. Thermal resistance is key.

- Weather Resistance

Exposure to rain, snow, ice, and sunlight can degrade chimney materials over time. Components with inherent weather resistance, such as concrete crown sealants and waterproof brick coatings, protect the chimney structure from moisture penetration and freeze-thaw damage. Example: A siloxane-based brick sealant repels water while allowing the masonry to breathe, preventing moisture buildup that can lead to cracking and spalling during freeze-thaw cycles. Weather effects need to be considered.

- Chemical Resistance

Chemicals present in flue gases, such as sulfur dioxide and nitrogen oxides, can react with chimney materials, causing degradation. Components that are resistant to these chemicals provide enhanced protection against premature failure. Example: Using a flue liner specifically designed for use with oil-burning appliances ensures resistance to the acidic byproducts of oil combustion, prolonging the liner’s lifespan. It is important to properly plan and choose the correct application.

The selection of chimney materials with inherent degradation resistance is a proactive approach to ensuring long-term chimney performance and safety. By minimizing the rate of material deterioration, these components contribute directly to the overall effectiveness and longevity of systems designed to preserve chimney health. It is a long term investment.

Frequently Asked Questions Regarding Chimney Protection

This section addresses common inquiries concerning methods to preserve chimney integrity and extend operational lifespan. These answers provide factual information based on industry standards and best practices.

Question 1: What constitutes a chimney cap, and why is its installation deemed necessary?

A chimney cap is a protective covering installed atop the chimney flue. Its necessity stems from its capacity to prevent precipitation, debris, and animal ingress, thereby mitigating water damage and flue obstruction.

Question 2: How frequently should a chimney undergo professional inspection?

Annual professional inspection is recommended, irrespective of usage frequency. This practice facilitates early detection of structural deficiencies, creosote accumulation, and other potential hazards.

Question 3: What are the indicators of chimney crown deterioration?

Indicators encompass visible cracks, spalling, and water staining. Prompt repair or reconstruction of the crown is essential to prevent further water infiltration and structural compromise.

Question 4: What is the function of a flue liner, and when is its replacement warranted?

A flue liner protects the chimney structure from corrosive flue gases. Replacement is warranted upon detection of cracks, deterioration, or improper sizing relative to the connected heating appliance.

Question 5: What are the primary consequences of neglecting creosote removal from a chimney flue?

Neglecting creosote removal elevates the risk of chimney fires, reduces heating system efficiency, and potentially compromises structural integrity.

Question 6: How does burning seasoned wood contribute to chimney preservation?

Burning seasoned wood minimizes creosote production due to its lower moisture content, thereby reducing the risk of chimney fires and extending the intervals between necessary cleanings.

Consistent application of these protective measures, alongside adherence to recommended maintenance schedules, will safeguard chimney structures and optimize performance.

The following segment explores advanced preservation techniques, designed to address specific challenges encountered in diverse chimney configurations.

In Conclusion

This exploration has underscored the multifaceted nature of chimney preservation. From addressing water intrusion and creosote buildup to reinforcing structural components and ensuring proper ventilation, a comprehensive strategy is essential. Material degradation resistance further contributes to long-term stability, necessitating careful selection of durable and appropriate components. Chimney Savers, therefore, represent a commitment to proactive maintenance, mitigating risks, and optimizing operational lifespan.

The enduring structural health and safety of a chimney system depend upon diligence and informed action. Consistent attention to detail, coupled with adherence to best practices, will ensure the continued safe and efficient operation. Homeowners are encouraged to prioritize regular inspections, address potential issues promptly, and consult with qualified professionals to implement effective long-term plans. By embracing a proactive approach, individuals contribute directly to the enduring integrity of this critical infrastructure.

![Why Chimney Birds Matter: [Chimney Bird] Care Tips Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Why Chimney Birds Matter: [Chimney Bird] Care Tips | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/03/th-25-300x200.jpg)