A structure, typically constructed of brick, stone, or metal, designed to vent combustion gases from a fireplace, furnace, or other heating appliance located in a building positioned near a sea or ocean. These structures are subject to unique environmental stressors due to their proximity to saltwater and marine weather patterns.

Their resilience is of paramount importance for maintaining indoor air quality and structural integrity in coastal buildings. Historically, such structures were essential for providing warmth and cooking facilities. Modern engineering emphasizes the need for robust materials and construction techniques to withstand the corrosive effects of salt spray, high winds, and frequent temperature fluctuations, thereby ensuring longevity and safe operation.

The following sections will delve into specific challenges faced by structures of this type in maritime environments, explore appropriate construction and maintenance strategies, and examine the impact of regulatory frameworks on their design and upkeep.

Practical Considerations for Structures Near the Shoreline

Maintaining the integrity of a structure designed for exhausting combustion byproducts in a marine environment requires diligence and adherence to established best practices. The following points outline essential steps for ensuring safe and efficient operation.

Tip 1: Material Selection: Employ corrosion-resistant materials such as stainless steel or specialized brick formulated for marine exposure. This minimizes degradation caused by salt air and moisture.

Tip 2: Regular Inspections: Conduct thorough visual examinations at least annually, or more frequently in areas prone to severe weather. Look for cracks, spalling, or evidence of water intrusion. Address any deficiencies promptly.

Tip 3: Protective Coatings: Apply a sealant or protective coating specifically designed to resist saltwater damage. Reapply as recommended by the manufacturer to maintain effectiveness.

Tip 4: Cap Installation: Fit a well-designed cap to prevent rainwater and debris from entering the flue. Ensure the cap is constructed of durable, corrosion-resistant material and is securely attached.

Tip 5: Professional Cleaning: Schedule professional cleaning by a qualified chimney sweep to remove creosote and other deposits. This reduces the risk of chimney fires and ensures efficient ventilation.

Tip 6: Mortar Joint Maintenance: Monitor mortar joints for erosion or cracking. Repoint deteriorated joints with a mortar mix formulated for marine environments to prevent water penetration and structural weakness.

Tip 7: Height Considerations: Ensure adequate height in accordance with local building codes and prevailing wind conditions. Proper height promotes effective draft and minimizes downdrafts caused by nearby structures or terrain.

By implementing these measures, property owners can significantly extend the lifespan and enhance the safety of structures that exhaust combustion byproducts along coastal areas, thereby mitigating potential hazards and ensuring the continued efficient operation of heating appliances.

The subsequent sections will address specific challenges associated with regulatory compliance and long-term planning for these specialized structures.

1. Material Degradation

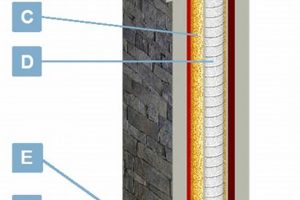

The proximity of a structure venting combustion byproducts to a marine environment subjects its components to accelerated degradation. This phenomenon stems primarily from the constant exposure to saltwater aerosols, which contain chlorides that aggressively corrode metals and weaken masonry. The porous nature of brick and mortar allows for the absorption of these chloride-laden solutions, initiating a process of internal decay. Freeze-thaw cycles further exacerbate the damage, as absorbed water expands upon freezing, causing cracks and spalling.

The consequences of unchecked material degradation can be severe, ranging from reduced structural stability to the potential for flue gas leaks. Leaks not only compromise the efficiency of the heating appliance but also pose a health risk due to the potential for carbon monoxide intrusion. For example, a common manifestation of this issue involves the corrosion of a metal flue liner, necessitating costly repairs or complete replacement. Another frequent example is the deterioration of brick and mortar, leading to a weakening of the overall structure and potential safety hazards. Selecting appropriate, corrosion-resistant materials during construction, coupled with regular inspections and maintenance, is critical for mitigating these risks.

Therefore, understanding the mechanisms and effects of material degradation is essential for ensuring the longevity and safe operation of coastal chimneys. Strategies to combat degradation, such as the use of specialized coatings, appropriate construction techniques, and regular maintenance, represent crucial components of a comprehensive approach to managing the unique challenges posed by marine environments. Ignoring these factors can lead to substantial repair costs, safety hazards, and premature failure of the structure.

2. Wind Resistance

In coastal regions, structures venting combustion byproducts are continuously subjected to high winds, making wind resistance a critical design parameter. These structures must withstand sustained winds and gusting conditions that can exert significant force, potentially leading to structural failure or operational inefficiencies. The effects of wind are amplified by the exposure of these structures, which are often taller than surrounding buildings to ensure adequate draft. Failure to adequately account for wind loads can result in cracking, tilting, or even collapse, particularly in older structures with compromised mortar joints. The geometry and materials of construction must be carefully considered to minimize wind resistance and ensure stability. For example, a poorly designed cap can act as a wind scoop, increasing the forces exerted on the stack and potentially causing damage.

Effective wind resistance is achieved through a combination of robust design principles and appropriate material selection. Reinforcement with steel or composite materials can enhance structural integrity, while aerodynamic shaping can reduce wind loads. Furthermore, proper anchoring to the building’s structure is essential to prevent overturning or dislodgement. Building codes in coastal areas often mandate specific wind load requirements that must be met to ensure the safety and durability of these structures. Regular inspections should include assessments of structural stability and the condition of anchoring systems. Any signs of movement or stress should be addressed promptly to prevent further damage.

The importance of wind resistance for coastal chimneys cannot be overstated. The cumulative effect of continuous wind exposure can lead to gradual deterioration and eventual failure if not properly addressed. A comprehensive understanding of wind dynamics, coupled with appropriate design and maintenance practices, is crucial for ensuring the safe and reliable operation of these structures in challenging coastal environments. Ignoring wind resistance can result in costly repairs, potential safety hazards, and a reduced lifespan of the structure.

3. Saltwater Corrosion

Saltwater corrosion presents a significant threat to the structural integrity and operational longevity of structures venting combustion byproducts located in coastal environments. The aggressive nature of saltwater, combined with the porous characteristics of common building materials, accelerates degradation and necessitates specialized preventative measures.

- Electrochemical Processes

Saltwater acts as an electrolyte, facilitating electrochemical reactions that corrode metals. Iron and steel components are particularly vulnerable, leading to rust formation and structural weakening. Example: Metal flue liners exposed to saltwater aerosols experience accelerated corrosion, potentially leading to flue gas leaks and reduced heating efficiency. Implication: Requires the use of corrosion-resistant alloys or protective coatings.

- Chloride Ion Penetration

Chloride ions from saltwater penetrate porous materials like brick and mortar, disrupting their chemical bonds and weakening the structure. This process is exacerbated by freeze-thaw cycles. Example: Mortar joints deteriorate rapidly, leading to water ingress and further structural decay. Implication: Necessitates the use of specialized mortars and sealants designed for marine environments.

- Differential Aeration

Variations in oxygen concentration on the surface of the structure create localized corrosion cells. Areas with lower oxygen concentrations become anodic and corrode more rapidly. Example: Crevices and areas sheltered from wind and sunlight experience accelerated corrosion due to reduced oxygen availability. Implication: Requires careful attention to design details and regular cleaning to prevent the accumulation of debris.

- Galvanic Corrosion

When dissimilar metals are in contact in the presence of saltwater, a galvanic couple is formed, leading to accelerated corrosion of the more anodic metal. Example: The contact between a stainless steel flue liner and a carbon steel support structure can result in galvanic corrosion of the steel. Implication: Requires the careful selection of compatible materials or the use of insulating barriers to prevent galvanic coupling.

The combined effects of these processes underscore the importance of employing appropriate materials, construction techniques, and maintenance strategies to mitigate the impact of saltwater corrosion on coastal chimneys. Ignoring these factors leads to premature failure, costly repairs, and potential safety hazards.

4. Building Codes

Building codes play a crucial role in ensuring the safety, durability, and performance of structures venting combustion byproducts in coastal regions. These codes establish minimum standards for design, construction, and maintenance, taking into account the unique environmental stressors prevalent in marine environments.

- Wind Load Requirements

Coastal areas are often subject to high winds, necessitating specific building code provisions for wind resistance. These provisions dictate the minimum wind loads that structures must withstand, influencing design parameters such as structural reinforcement, anchoring systems, and material selection. Example: Codes may require a structure to withstand sustained winds of a certain velocity, dictating the use of reinforced concrete or steel construction. Implications: Compliance with wind load requirements minimizes the risk of structural failure and ensures the safety of occupants and surrounding property.

- Corrosion Resistance Standards

The corrosive effects of saltwater necessitate the use of corrosion-resistant materials and construction techniques. Building codes often specify minimum standards for the corrosion resistance of materials used in coastal construction, including requirements for protective coatings, specialized alloys, and cathodic protection systems. Example: Codes may mandate the use of stainless steel or epoxy-coated rebar in concrete structures to prevent corrosion. Implications: Adherence to corrosion resistance standards extends the lifespan of structures and reduces the risk of costly repairs.

- Seismic Design Considerations

Coastal regions are often located in seismically active areas, requiring building codes to address seismic design considerations. These provisions aim to ensure that structures can withstand earthquake forces without collapsing or sustaining significant damage. Example: Codes may require structures to be designed with reinforced shear walls or base isolation systems to mitigate the effects of ground motion. Implications: Compliance with seismic design requirements protects occupants and minimizes property damage during earthquakes.

- Floodplain Regulations

Many coastal areas are located in floodplains, making it essential for building codes to address flood risk management. These regulations may restrict construction in certain flood-prone areas or require structures to be elevated above the base flood elevation. Example: Codes may prohibit the construction of habitable structures below a certain elevation or require the use of flood-resistant materials. Implications: Compliance with floodplain regulations reduces the risk of flood damage and protects property values.

The enforcement of building codes is essential for mitigating the risks associated with coastal environments. Regular inspections and plan reviews ensure that structures meet the required standards and are constructed in a safe and durable manner. By adhering to building codes, communities can minimize the impact of natural disasters and create resilient infrastructure that can withstand the challenges of coastal living.

5. Proper Ventilation

Effective evacuation of combustion byproducts is fundamentally linked to the design and maintenance of coastal chimneys. Insufficient venting creates conditions conducive to carbon monoxide accumulation, posing a severe health hazard to building occupants. In coastal environments, proper ventilation is further complicated by prevailing winds, which can induce downdrafts, reversing the intended flow of exhaust gases. Furthermore, salt air accelerates the deterioration of internal flue components, potentially obstructing the passageway and impeding ventilation. For example, if a chimney lacks a properly sized and positioned cap, wind-driven rain and debris can enter the flue, restricting airflow and diminishing the chimney’s draft capabilities. This, in turn, can lead to incomplete combustion and a buildup of hazardous gases within the dwelling. A real-life example of a poorly ventilated chimney can be seen in older coastal homes where chimney flues have become blocked by bird nests or deteriorated mortar, resulting in carbon monoxide poisoning events.

The practical significance of understanding this connection lies in implementing proactive measures to ensure unrestricted airflow. This includes regular professional inspections to identify and rectify obstructions, the selection of appropriate chimney height and diameter based on appliance specifications and prevailing wind conditions, and the use of corrosion-resistant materials in chimney construction. Routine cleaning removes soot and creosote deposits, which are particularly problematic with certain fuel types and can significantly reduce ventilation efficiency. Furthermore, the installation of a properly designed chimney cap not only prevents debris intrusion but also enhances draft by stabilizing airflow, even in windy conditions. Building codes in coastal regions often mandate specific ventilation requirements, underscoring the importance of adherence to established safety standards.

In summary, proper ventilation is an indispensable component of any functioning coastal chimney system. Its absence not only compromises heating efficiency but also poses significant safety risks. Addressing the unique challenges presented by marine environments through diligent maintenance, appropriate design, and adherence to building codes is paramount for ensuring the safe and effective venting of combustion byproducts and safeguarding the health of building occupants. The cumulative effect of neglecting ventilation leads to compromised air quality, increased risk of carbon monoxide poisoning, and accelerated deterioration of the chimney structure itself.

6. Regular Maintenance

Regular maintenance constitutes a critical component in preserving the functionality, safety, and structural integrity of structures venting combustion byproducts in coastal environments. The harsh conditions characteristic of these regions necessitate a proactive approach to maintenance, mitigating the accelerated degradation caused by saltwater, wind, and temperature fluctuations. Neglecting routine upkeep can lead to significant damage, posing safety hazards and incurring substantial repair costs.

- Flue Inspection and Cleaning

Creosote buildup within the flue represents a significant fire hazard and impedes proper ventilation. Regular inspections by qualified professionals identify potential blockages, cracks, or deterioration. Cleaning removes creosote and other deposits, ensuring efficient and safe exhaust of combustion gases. Example: Coastal homes using wood-burning stoves often experience rapid creosote accumulation due to increased humidity. Implications: Reduces fire risk and improves heating system efficiency.

- Mortar Joint Assessment and Repair

Mortar joints are particularly vulnerable to saltwater intrusion and freeze-thaw cycles. Regular assessment identifies eroded, cracked, or missing mortar. Repointing deteriorated joints prevents water penetration, preserving structural stability. Example: Older brick structures along the coast frequently exhibit spalling and crumbling mortar. Implications: Prevents water damage, maintains structural integrity, and extends the lifespan of the structure.

- Cap and Spark Arrestor Inspection

Caps prevent rainwater, debris, and animals from entering the flue, while spark arrestors mitigate the risk of wildfire ignition. Regular inspection ensures these components are intact, secure, and functioning effectively. Example: Coastal storms can dislodge or damage caps, allowing water to enter the flue. Implications: Prevents water damage, maintains proper draft, and reduces the risk of chimney fires.

- Corrosion Protection

Metal components, such as flue liners and support structures, are susceptible to corrosion in marine environments. Regular inspection identifies signs of rust or deterioration. Application of protective coatings and rust inhibitors extends the lifespan of these components. Example: Metal flue liners exposed to saltwater aerosols often exhibit accelerated corrosion. Implications: Prevents flue gas leaks, maintains structural integrity, and extends the lifespan of metal components.

These multifaceted aspects of regular maintenance are essential for mitigating the specific challenges faced by structures venting combustion byproducts in coastal areas. Proactive upkeep minimizes the risk of structural failure, enhances safety, and prolongs the operational lifespan of these critical building components. Failure to prioritize regular maintenance results in accelerated degradation, increased safety hazards, and ultimately, higher long-term costs.

7. Water Intrusion

Water intrusion represents a significant threat to structures venting combustion byproducts in coastal environments, initiating a cascade of detrimental effects that compromise both structural integrity and operational safety. The porous nature of common building materials, such as brick and mortar, facilitates the absorption of rainwater and saltwater aerosols, creating pathways for water to penetrate the structure’s core. The combination of constant moisture exposure and the presence of chlorides from saltwater accelerates the degradation process, leading to spalling, cracking, and the weakening of mortar joints. This process is further exacerbated by freeze-thaw cycles, where water expands upon freezing, exerting pressure on the surrounding materials and causing further damage. As an example, consider a chimney constructed from traditional brick and mortar, located near a coastline. Over time, the mortar joints will absorb moisture and chloride ions, leading to a gradual erosion of the mortar and the eventual loosening of the bricks. During winter months, the absorbed water freezes and expands, causing the bricks to crack and spall, compromising the structural stability of the chimney. This not only poses a safety hazard but also reduces the efficiency of the heating system, as water-saturated materials require more energy to heat.

The practical significance of understanding the connection between water intrusion and coastal chimneys lies in the implementation of proactive measures to mitigate its effects. This includes the application of water-repellent sealants to the exterior surfaces, the use of specialized mortars designed for marine environments, and the installation of properly designed chimney caps to prevent rainwater from entering the flue. Regular inspections are essential to identify and address early signs of water damage, such as cracks or spalling. Repointing deteriorated mortar joints can prevent further water penetration and restore structural integrity. Furthermore, proper ventilation is crucial for allowing moisture to escape from the chimney, preventing the buildup of condensation and reducing the risk of freeze-thaw damage. For example, homeowners can apply a breathable, water-repellent sealant to the chimney’s exterior every few years to prevent water from being absorbed into the brick and mortar. Regularly checking and cleaning the chimney cap will ensure it effectively diverts rainwater and prevents debris from entering the flue.

In summary, water intrusion poses a serious threat to the long-term viability of coastal chimneys. The combination of saltwater exposure, porous materials, and freeze-thaw cycles accelerates degradation, compromising structural integrity and posing safety hazards. A comprehensive approach to mitigation involves the use of appropriate materials, protective coatings, regular inspections, and proactive maintenance. Addressing this challenge is essential for ensuring the safe and efficient operation of these critical building components, as well as for preserving the structural integrity of coastal properties. Neglecting water intrusion can lead to costly repairs, safety risks, and a reduced lifespan for the chimney.

Frequently Asked Questions

The following questions address common concerns regarding the maintenance, construction, and safety of structures venting combustion byproducts in coastal environments.

Question 1: What specific materials are recommended for building or repairing a structure designed for exhausting combustion byproducts in a marine environment?

The selection of materials for these structures in coastal areas necessitates careful consideration of corrosion resistance. Stainless steel, particularly grades 316 or higher, is highly recommended for flue liners and other metal components. For masonry structures, specialized bricks and mortars formulated for marine exposure should be employed to minimize degradation caused by salt spray and moisture penetration.

Question 2: How frequently should a coastal chimney be inspected?

Given the accelerated degradation processes prevalent in coastal environments, annual inspections conducted by a qualified professional are considered essential. More frequent inspections may be warranted in areas prone to severe weather events or if signs of damage are observed.

Question 3: What are the primary indicators of saltwater corrosion in structures venting combustion byproducts?

Key indicators include the presence of rust on metal components, spalling or cracking of brick and mortar, and the deterioration of mortar joints. Efflorescence, a white, powdery deposit on the surface of masonry, can also indicate saltwater intrusion.

Question 4: How does wind impact the performance of a coastal chimney, and what measures can mitigate these effects?

Prevailing winds can induce downdrafts, reversing the intended flow of exhaust gases. Implementing effective measures such as increasing the height, installing a properly designed cap, or using wind-resistant flue designs can mitigate these effects.

Question 5: Are there specific building code requirements for structures designed for exhausting combustion byproducts in coastal regions?

Yes, building codes in coastal areas often include specific provisions for wind loads, corrosion resistance, and flood risk management. It is imperative to consult local building officials and adhere to all applicable regulations during construction and maintenance.

Question 6: What is the significance of creosote buildup in the flue of a coastal chimney, and how can it be prevented?

Creosote is a flammable byproduct of incomplete combustion. Its buildup in the flue poses a significant fire hazard. Regular cleaning by a qualified chimney sweep is essential for removing creosote and preventing chimney fires. Employing proper burning techniques and using seasoned wood can minimize creosote formation.

Maintaining the structural integrity and operational safety of structures designed for exhausting combustion byproducts in coastal environments requires diligence, adherence to established best practices, and a thorough understanding of the unique challenges posed by marine environments.

The subsequent sections will delve into specific challenges associated with regulatory compliance and long-term planning for these specialized structures.

Coastal Chimney

This exploration has elucidated the critical considerations surrounding the design, maintenance, and safety of the coastal chimney. The corrosive effects of saltwater, the persistent forces of wind, and the potential for water intrusion collectively demand a proactive and informed approach. Material selection, regular inspections, and adherence to building codes are not merely recommendations but essential components of a responsible strategy.

The long-term viability of these structures hinges on a commitment to diligent upkeep and an understanding of the unique challenges presented by marine environments. Ignoring these factors leads to compromised safety, increased repair costs, and potential structural failure. Therefore, a proactive approach to maintenance and a thorough understanding of the risks are essential for ensuring the longevity and safe operation of every coastal chimney.

![Why Chimney Birds Matter: [Chimney Bird] Care Tips Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Why Chimney Birds Matter: [Chimney Bird] Care Tips | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/03/th-25-300x200.jpg)