The riddle poses a paradox regarding directionality and physical properties. Soot, smoke, and flames are common examples that ascend a chimney due to heat convection, yet, in their altered gaseous state or as dissipated energy, cannot descend. This relates to fundamental principles of thermodynamics and the behavior of matter under varying conditions.

Understanding this concept highlights the nature of energy transfer and material transformation. Historically, chimney design has aimed to optimize this upward flow, ensuring efficient removal of combustion byproducts. The riddle encapsulates this relationship between physics, design, and everyday observation.

The following discussion will expand on the forces at play, the design considerations for effective chimney function, and the broader implications of understanding directional movement in dynamic systems.

Chimney Optimization Guidance

The principles illustrated by the riddle of upward movement in a chimney provide insight into optimizing its function and preventing potential issues.

Tip 1: Regular Inspections: Implement a scheduled chimney inspection protocol to identify potential obstructions, such as creosote buildup or animal nests, which can impede proper upward flow and increase fire risk.

Tip 2: Appropriate Fuel Selection: Ensure the use of seasoned, dry wood to minimize smoke production. Wet or unseasoned wood creates excessive smoke and creosote, hindering upward movement and increasing chimney maintenance needs.

Tip 3: Proper Chimney Sizing: Verify the chimney’s dimensions are correctly matched to the heating appliance. An improperly sized chimney can result in poor draft, preventing efficient upward flow of combustion gases.

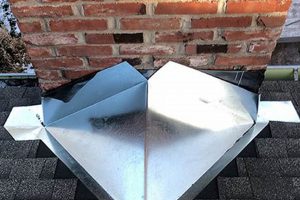

Tip 4: Caps and Screens: Install a chimney cap with a spark arrestor screen to prevent rain, snow, and debris from entering the chimney while maintaining optimal airflow and preventing the escape of embers.

Tip 5: Avoid Downward Obstructions: Eliminate any external factors, such as nearby trees or structures, that may impede wind flow and create a downward draft, counteracting the intended upward movement of gases.

Tip 6: Professional Cleaning: Schedule regular professional chimney cleaning to remove creosote and other deposits. This preventative measure ensures unrestricted upward flow and minimizes the risk of chimney fires.

Tip 7: Damper Maintenance: Ensure the chimney damper operates smoothly and seals properly when closed. A faulty damper can allow cold air to descend, negatively impacting draft and increasing heating costs.

Adhering to these guidelines promotes efficient chimney operation, reduces fire hazards, and ensures the safe and effective removal of combustion byproducts. This understanding allows for proactive management and preventative maintenance, safeguarding property and well-being.

The ensuing discussion will delve into advanced troubleshooting techniques and innovative chimney technologies designed to further enhance performance and safety.

1. Convection's Upward Thrust

Convection’s upward thrust is a fundamental principle governing the movement of combustion products within a chimney system. This force is the primary driver behind the riddle “what can go up a chimney but not down,” dictating the directional flow of gases and particulate matter.

- Heat as the Initiator

The combustion process generates significant heat, causing the air and gases within the firebox to expand and become less dense than the surrounding cooler air. This density difference creates a buoyant force, initiating the upward movement. The initial heat input is crucial; without it, the directional flow would not occur.

- Density Gradient and Air Pressure

The temperature gradient within the chimney creates a corresponding density gradient. Warm, less dense air rises, creating a zone of lower pressure at the base of the chimney. This pressure differential draws in fresh air to sustain the combustion process and simultaneously propels the heated gases upward. This pressure dynamic is essential for the efficient expulsion of exhaust.

- Chimney Design and Stack Effect

Chimney design leverages the stack effect, enhancing convection’s upward thrust. Taller chimneys create a greater temperature difference between the inside and outside air, resulting in a stronger upward draft. The chimney’s dimensions and insulation also play a role in maintaining consistent temperature and optimizing the stack effect.

- Factors Affecting Convection: Obstructions and Downdrafts

Obstructions within the chimney, such as creosote buildup or debris, impede the smooth upward flow of gases, reducing the effectiveness of convection. Similarly, external factors like wind direction and nearby structures can create downdrafts, counteracting the upward thrust and potentially causing backdrafting of harmful gases into the living space. Mitigation measures are vital to ensure consistent upward convection.

The interplay of heat, density gradients, chimney design, and potential obstructions underscores the complexity of convection’s role. The inability of smoke, soot, or heat to reverse their upward trajectory once dispersed or cooled directly relates to the fundamental principles of thermodynamics and the ongoing energy input that drives the initial convective process. The riddle serves as a simplified illustration of these intricate dynamics.

2. Gas Expansion Dynamics

Gas expansion dynamics are intrinsically linked to the riddle “what can go up a chimney but not down.” The principles of thermodynamics dictate the behavior of gases under varying conditions, specifically as they relate to temperature and pressure within a chimney system. This expansion is a crucial component of the upward flow, precluding the reverse trajectory implicit in the riddle.

- Thermal Expansion and Buoyancy

Combustion processes generate heat, causing gases to undergo thermal expansion. This expansion reduces the density of the gases, making them buoyant relative to the cooler, denser ambient air outside the chimney. This buoyancy is the primary driving force behind the upward draft. The expanded gases, lighter than the surrounding air, are propelled upwards, fulfilling the “up” component of the riddle. Once these gases cool significantly at altitude they are no longer buoyant, so are unable to move back down.

- Pressure Gradients and Flow Rate

The expansion of gases creates a pressure gradient within the chimney. The heated, expanded gases exert pressure that is lower than the pressure outside the chimney at lower levels. This pressure differential establishes a flow rate, dictating the speed at which the gases ascend. A greater temperature differential results in a greater pressure difference and a faster flow rate. Inability to reverse the gas compression means there is no driving force that would allow them to descend.

- Volume Increase and Ascent

As gases heat, they increase significantly in volume. This volumetric increase, coupled with reduced density, contributes to the forceful ejection of combustion byproducts out of the chimney. The expansion is not merely a change in density, but a physical enlargement of the gas volume that aids in its upward trajectory. As the volume increase is dependent on the increased heat from the fire, once the gases dissipate into cooler air they no longer have the thermal energy to re-compress and move down.

- Ideal Gas Law and Chimney Function

The Ideal Gas Law (PV=nRT) directly applies to chimney function. Increased temperature (T) results in increased volume (V) and/or pressure (P), driving the upward flow. The number of moles (n) of gas remains relatively constant during the initial ascent. However, as the gases cool in the upper reaches of the chimney and atmosphere, the temperature drops, volume diminishes, and the gases disperse. As these gases mix and cool, their density increases approaching that of the surrounding air, halting any reverse trajectory.

The interplay of thermal expansion, pressure gradients, and volume changes, governed by the Ideal Gas Law, collectively explains the upward movement of combustion products in a chimney. The dispersion of these gases into the atmosphere, accompanied by cooling and condensation, makes their return impossible, directly addressing the paradoxical nature of “what can go up a chimney but not down.” The expansion is a one-way process in the chimney environment, barring external factors or design flaws that might disrupt the intended flow.

3. Transformed Matter State

The riddle relies heavily on the concept of transformed matter states during and after combustion. Solid fuel, through burning, becomes primarily gaseous and particulate matter. This transformation facilitates upward movement but precludes the reverse trajectory.

- Solid to Gas Transition

Combustion converts solid fuels, such as wood or coal, into gaseous products like carbon dioxide, water vapor, and other volatile organic compounds. This phase transition from a condensed state to a dispersed gaseous state enables the combustion products to ascend the chimney due to buoyancy and convective forces. The original solid material no longer exists in its initial form, making a downward return impossible. The inherent nature of irreversible chemical reaction prevents back-tracking.

- Particulate Matter Dispersion

Incomplete combustion generates particulate matter, including soot and ash. These solid particles are entrained within the hot gas stream and carried upward. However, as the gases cool and disperse in the atmosphere, the particulate matter settles out or undergoes further chemical reactions. The dispersed nature of these particles, spread over a large area, prevents their concentrated return down the chimney. This demonstrates a significant change of state from a concentrated form to a distributed state, hindering a downward motion.

- Energy Dissipation and Molecular Change

The chemical bonds within the fuel are broken during combustion, releasing energy in the form of heat and light. The molecular structure of the original fuel is fundamentally altered. The resulting simpler molecules and the released energy dissipate into the environment. This dissipation of energy and transformation of molecular structure preclude the reverse process of spontaneously reforming the original fuel within the chimney and returning downward. The chemical changes are irreversible without significant energy input to reverse the reaction.

- Condensation and Deposition

As the hot gases rise and cool within the chimney, some of the volatile components may condense and deposit on the chimney walls as creosote. This creosote represents a changed state of matter, no longer in its original gaseous form but rather a solid or liquid deposit. This deposition further reduces the mass of ascending material and prevents its return down the chimney in the original gaseous state. This adherence to the chimney surfaces effectively removes those particles from the upward flow and prevents any possibility of descent.

These transformations, from solid to gas, the dispersion of particulate matter, energy dissipation accompanying molecular change, and condensation processes, collectively explain why the products of combustion ascend but cannot descend a chimney. The changes in physical and chemical states irreversibly alter the material, satisfying the conditions of the riddle and highlighting fundamental principles of chemistry and physics.

4. Energy Dissipation

Energy dissipation plays a crucial role in understanding why certain substances ascend a chimney but do not subsequently descend. The phenomenon involves the irreversible conversion of concentrated energy into less usable forms, influencing the state and directionality of combustion byproducts.

- Thermal Energy Loss

Combustion generates thermal energy, which initially drives the upward flow of gases within the chimney. However, as these gases rise, they lose heat to the surrounding environment through conduction, convection, and radiation. This thermal energy dissipation reduces the buoyancy of the gases, diminishing their upward momentum. Importantly, the lost heat does not spontaneously re-concentrate to reverse the direction of flow.

- Friction and Air Resistance

The movement of gases through the chimney involves frictional forces between the gas molecules and the chimney walls, as well as air resistance from the surrounding atmosphere. These forces convert some of the kinetic energy of the ascending gases into thermal energy, which is then dissipated into the environment. The energy expended to overcome these frictional forces is non-recoverable, contributing to the prevention of downward movement.

- Phase Transitions and Latent Heat

Combustion products, such as water vapor, may undergo phase transitions as they cool within the chimney. For instance, water vapor can condense into liquid water, releasing latent heat. This released heat dissipates into the environment, preventing the condensed water from spontaneously re-vaporizing and returning downward as a gas. The conversion of energy into latent heat represents a loss from the system that cannot be reversed without external energy input.

- Chemical Reactions and Irreversibility

Combustion involves complex chemical reactions that release energy. These reactions are generally irreversible under the conditions present in a chimney. The products of combustion, such as carbon dioxide and water, do not spontaneously revert back into their original forms and descend. The dissipated energy, used to break chemical bonds during combustion, is not recoverable under typical chimney conditions, reinforcing the one-way directional flow.

These processes of energy dissipation thermal loss, friction, phase transitions, and chemical irreversibility collectively explain the unidirectional nature of flow in a chimney. Once energy is dissipated, the original state and upward momentum cannot be restored without external intervention, thus preventing the combustion byproducts from reversing their course and moving downwards. The principle underscores the thermodynamic basis of “what can go up a chimney but not down.”

5. One-Way Flow

The principle of one-way flow is central to the riddle. A chimney is designed to facilitate the upward passage of combustion byproducts and simultaneously prevent their downward return. This unidirectional movement is not merely a desirable outcome; it is a critical functional requirement essential for safe and efficient operation. A chimney’s design, operating parameters, and maintenance protocols are all geared towards ensuring and maintaining this one-way flow.

For example, the height of a chimney is calculated to create sufficient draft, a pressure differential that encourages upward movement. Internal obstructions, such as accumulated creosote or debris, impede this upward flow and, in severe cases, can cause backdrafting, where combustion gases enter the living space. Proper chimney maintenance, including regular cleaning, aims to preserve the designed one-way airflow. Downdrafts, caused by external wind conditions or nearby structures, can also disrupt this one-way flow, demonstrating the fragility of the system’s design and highlighting the importance of proper installation and site selection. Furthermore, chimney caps are designed to allow unobstructed upward airflow while preventing rain and debris from entering and disrupting the desired unidirectional movement.

Understanding and maintaining one-way flow in chimney systems is paramount for preventing carbon monoxide poisoning, reducing fire hazards, and ensuring efficient fuel combustion. Disruptions to this flow have potentially life-threatening consequences. The functional imperative of one-way flow underscores the practical significance of the riddle, emphasizing its connection to real-world safety and efficiency considerations. The seemingly simple puzzle therefore embodies essential principles of physics and engineering.

Frequently Asked Questions

This section addresses common queries regarding the riddle’s underlying principles and their practical implications for chimney function and safety.

Question 1: Why can smoke ascend a chimney but not descend?

Smoke rises due to heat-induced convection and gas expansion. Once it cools and dissipates into the atmosphere, its density increases, and the driving forces that propelled it upward cease to exist, precluding downward movement.

Question 2: Does the chimney’s height influence the upward movement of combustion gases?

Yes, chimney height significantly impacts draft. A taller chimney creates a greater temperature difference between the interior and exterior air, enhancing the stack effect and promoting a stronger upward flow.

Question 3: What factors can impede the upward flow of gases in a chimney?

Obstructions such as creosote buildup, debris, animal nests, and downdrafts caused by wind or nearby structures can impede the upward flow, potentially leading to backdrafting.

Question 4: How does regular chimney cleaning contribute to safe and efficient operation?

Regular cleaning removes creosote and other deposits, ensuring an unobstructed passageway for combustion gases. This minimizes the risk of chimney fires and maintains optimal draft, improving heating efficiency.

Question 5: What role does a chimney cap play in maintaining proper airflow?

A chimney cap prevents rain, snow, and debris from entering the chimney, while still allowing combustion gases to escape unimpeded. It also includes a spark arrestor to prevent embers from exiting and potentially causing fires.

Question 6: Are there situations where combustion gases might descend a chimney?

Yes, downdrafts caused by adverse wind conditions or improperly designed chimney systems can reverse the normal upward flow, causing combustion gases to enter the living space. This poses a serious safety hazard.

Understanding these principles is crucial for ensuring safe and efficient chimney operation. Regular maintenance and careful attention to chimney design can mitigate potential risks.

The following section will explore advanced technologies for enhancing chimney performance and safety.

Understanding Directional Flow

The examination of “what can go up a chimney but not down” reveals fundamental principles of physics and chemistry at play within a common household structure. The upward movement of smoke, heat, and combustion byproducts is driven by convection, gas expansion, and transformation of matter. These processes, combined with energy dissipation and the designed one-way flow, prevent a reverse trajectory.

Therefore, maintaining the integrity of the chimney system is paramount for safety and efficiency. Regular inspections, proper cleaning, and adherence to best practices are essential. Continued vigilance and a commitment to preventative measures will ensure the reliable and safe functioning of this critical component of residential heating systems.