Structures designed to vent combustion gases and smoke from fireplaces, furnaces, and other heating appliances in the Houston, Texas, metropolitan area are subject to specific environmental conditions and regulatory requirements. These structures are essential for maintaining indoor air quality and preventing the accumulation of harmful substances. As an example, residential properties throughout Harris County utilize these systems to safely expel byproducts of natural gas-fueled heating.

The proper function of these systems is critical for health and safety, contributing to the reduction of carbon monoxide poisoning and fire hazards. Furthermore, adherence to local building codes ensures structural integrity and minimizes environmental impact. Historically, the design and materials used in these structures have evolved to address the region’s climate, including high humidity and the potential for extreme weather events such as hurricanes.

The following sections will delve into specific aspects relating to the inspection, maintenance, repair, and regulatory considerations for residential and commercial venting systems in the Houston area.

Essential Advice for Venting Systems in Houston

Maintaining the integrity and functionality of venting systems is crucial for the safety and efficiency of residential and commercial properties. The following tips provide guidance on ensuring optimal performance and longevity.

Tip 1: Schedule Regular Inspections: Annual inspections by qualified professionals are essential to identify potential issues such as cracks, blockages, or deterioration. Early detection can prevent costly repairs and hazardous conditions. For instance, creosote buildup, a common occurrence, can be addressed before it becomes a fire hazard.

Tip 2: Address Water Damage Promptly: Water intrusion can significantly compromise the structure and lead to deterioration. Leaks should be identified and repaired immediately to prevent further damage. Check flashing around the structure where it meets the roof, as this is a common entry point for water.

Tip 3: Ensure Proper Ventilation: Adequate ventilation is critical for efficient combustion and the safe removal of exhaust gases. Blockages or obstructions can lead to carbon monoxide buildup indoors. Regularly check for any signs of obstructions and ensure proper airflow.

Tip 4: Use Appropriate Fuel Types: The type of fuel used in heating appliances can impact the accumulation of byproducts and the lifespan of the venting system. Adhering to manufacturer recommendations for fuel types is crucial. Deviation from these recommendations can accelerate deterioration and increase the risk of malfunction.

Tip 5: Maintain Cleanliness: Regular cleaning removes debris and accumulated soot, ensuring optimal airflow and reducing the risk of chimney fires. Hire certified technicians for professional cleaning services. The frequency of cleaning depends on usage, but at least annually is recommended.

Tip 6: Consider Professional Repairs: Attempting DIY repairs on venting systems can be hazardous and may violate local building codes. Entrust repairs to qualified professionals with experience and certification.

Adhering to these guidelines will contribute to the safe and efficient operation of venting systems, reducing the risk of fire hazards, carbon monoxide poisoning, and costly repairs.

The subsequent sections will explore specific considerations for selecting qualified service providers and understanding local regulations.

1. Inspections

In the Houston, Texas area, routine inspections of venting systems are paramount for maintaining safety and code compliance. These inspections identify potential hazards and ensure the proper functionality of systems exposed to the region’s climate and environmental factors.

- Level 1 Visual Inspection

This basic inspection involves a visual examination of readily accessible components. Technicians look for visible signs of damage, deterioration, or obstructions. For example, a Level 1 inspection might reveal cracked masonry or a bird’s nest obstructing the flue. This level is typically performed during a routine service call or homeowner request and is generally sufficient for systems under continued, normal use.

- Level 2 Inspection with Video Scanning

A Level 2 inspection is required when changes have been made to the system, such as fuel type or appliance replacement, or if a Level 1 inspection reveals potential issues. This involves a more thorough examination, often including video scanning of the flue to identify internal damage or obstructions not visible from the outside. For example, this type of inspection could detect hidden cracks in the liner or excessive creosote buildup, commonly found in systems connected to wood-burning appliances.

- Structural Integrity Assessment

Inspections assess the structural stability of the system, particularly critical in Houston due to the area’s susceptibility to storms and high winds. Technicians examine the system for leaning, cracking, or other signs of structural compromise. For instance, water damage from prolonged exposure to rain can weaken the mortar, requiring timely repairs to prevent collapse.

- Code Compliance Verification

Inspections ensure adherence to local building codes, which regulate the construction, maintenance, and operation of venting systems. Technicians verify that the system meets current code requirements, addressing issues such as proper clearances, ventilation, and material standards. Non-compliance can result in fines and the requirement for corrective action, impacting property owners.

These inspection levels are crucial for ensuring the safe and efficient operation of venting systems. Regular and thorough inspections help prevent potential hazards, maintain property value, and ensure compliance with local regulations in the Houston metropolitan area.

2. Repairs

Venting system repairs in Houston, TX, represent a critical aspect of property maintenance and safety. Damage resulting from environmental factors, age, or improper use necessitates timely intervention to prevent escalating issues. A primary concern is water damage, given Houston’s humid climate and susceptibility to heavy rainfall. Moisture intrusion can degrade the structural integrity of masonry, leading to spalling and eventual collapse. Such deterioration compromises the venting system’s ability to safely expel combustion byproducts, potentially leading to carbon monoxide buildup indoors.

Repairs also address issues like creosote accumulation in systems connected to wood-burning fireplaces. Creosote, a highly flammable byproduct of incomplete combustion, poses a significant fire hazard if not removed regularly. Cracked or deteriorated liners are another common repair issue. These liners serve to contain combustion gases and protect surrounding building materials from heat and corrosive byproducts. Failing liners can lead to flue gas leaks and structural damage. Furthermore, damage from severe weather, such as high winds and lightning strikes, can necessitate extensive repairs, including rebuilding sections or replacing damaged components.

Effective repairs require qualified professionals with expertise in venting system construction and local building codes. Timely and appropriate repairs not only restore functionality and safety but also prevent more extensive and costly damage in the long term. Addressing issues promptly ensures the continued safe operation of heating appliances and compliance with regulatory requirements.

3. Cleaning

The regular cleaning of venting systems within the Houston, Texas metropolitan area is a crucial preventative measure for ensuring operational safety and efficiency. Accumulated deposits and debris can impede airflow, increase the risk of fire, and compromise the system’s ability to vent harmful gases. The specifics of cleaning vary based on the type of system and fuel used; however, the underlying principle remains consistent: maintaining a clear and unobstructed flue.

- Creosote Removal

Creosote, a byproduct of burning wood, accumulates inside the flue. This substance is highly flammable and poses a significant fire hazard. Professional cleaning involves removing creosote buildup to reduce the risk of chimney fires. For example, wood-burning fireplaces in Houston homes require periodic cleaning to prevent dangerous creosote accumulation, particularly during the winter months.

- Debris Removal

Leaves, branches, and animal nests can obstruct the flue, impeding airflow and potentially leading to carbon monoxide buildup inside the residence. Cleaning involves removing these obstructions to ensure proper venting. An example of this is removing a bird’s nest blocking the flue during the spring migration season.

- Soot Removal

Soot accumulation, a byproduct of burning various fuels, can restrict airflow and reduce the efficiency of the heating system. Cleaning involves removing soot deposits to maintain optimal performance. An example is removing soot from a gas furnace venting system to ensure efficient and safe operation during the winter.

- Inspection During Cleaning

The cleaning process often includes a basic inspection of the venting system, allowing technicians to identify potential issues such as cracks, deterioration, or other damage. Early detection of these problems allows for timely repairs, preventing more significant and costly issues in the future. For example, a technician might notice a cracked flue tile during a cleaning and recommend further inspection or repair.

These facets of cleaning are essential for maintaining the safety and efficiency of venting systems. Regular cleaning, combined with professional inspections and timely repairs, ensures that systems operate safely and efficiently, preventing potential hazards and prolonging their lifespan.

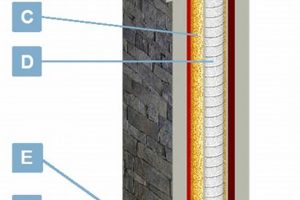

4. Liners

Venting system liners in the Houston, TX, area are critical components designed to protect the structural integrity of the system and ensure the safe and efficient venting of combustion byproducts. The liners, typically constructed of materials like stainless steel or clay, form a protective barrier against corrosive gases, moisture, and extreme temperatures. The connection to location is defined by local environmental factors like high humidity and seasonal temperature fluctuations, all of which exert added stress on venting systems. Without a properly installed and maintained liner, these elements can degrade the masonry or metal structure, leading to cracks, leaks, and eventual failure. For instance, a homeowner in Houston might experience water damage within their home due to a deteriorated liner allowing rainwater to seep into the chimney structure.

The practical application of liners extends to preventing carbon monoxide intrusion. A damaged or absent liner allows harmful gases to escape into the living space, posing a significant health risk. Furthermore, liners improve draft efficiency, which ensures complete combustion and reduces creosote buildup. In wood-burning systems, a properly sized and installed liner can dramatically decrease the accumulation of creosote, thereby reducing the risk of fires. This aspect is particularly relevant in older Houston homes where original systems may not meet current safety standards. Local regulations often mandate liner installation or upgrades during renovations or when replacing heating appliances, underlining the practical significance of these components.

In summary, liners are vital for the safety, efficiency, and longevity of venting systems, particularly in the challenging climatic conditions of Houston. Proper liner selection, installation, and maintenance are essential for protecting properties, preventing hazards, and ensuring compliance with local building codes. Challenges include the correct identification of suitable liner materials for specific applications and the need for skilled professionals to perform installations accurately. Regular inspection is critical to identify liner damage early and address it preventatively, reinforcing the broader theme of maintaining safe and efficient heating systems.

5. Caps

Caps, as components of venting systems in Houston, TX, serve a critical function in protecting the structure from environmental elements and preventing obstructions. The design and proper installation of these caps directly impact the longevity and operational efficiency of the system. Without a cap, rainwater can enter the system, leading to corrosion and deterioration of the flue liner and interior masonry. Furthermore, the absence of a cap provides an entry point for animals such as birds and squirrels, which can build nests and obstruct the flue. A blocked flue can cause dangerous carbon monoxide buildup indoors and impede the proper venting of combustion byproducts. For example, a Houston homeowner neglecting to replace a damaged cap might experience water damage in their firebox after a heavy rain, as well as discover a squirrels nest obstructing the flue. The practical significance lies in understanding that a small, relatively inexpensive cap can prevent costly repairs and potential safety hazards.

The selection of appropriate cap materials is also important. In Houston, where humidity and rainfall are high, caps constructed of stainless steel or copper offer superior resistance to corrosion compared to galvanized steel. Additionally, mesh screening is a common feature of caps, designed to prevent animals and debris from entering the system while still allowing for proper ventilation. The mesh size must be carefully selected to balance airflow and protection. For example, a cap with too-fine mesh can become clogged with soot and debris, restricting airflow and negatively affecting appliance performance. Caps also play a role in spark arrest, particularly important for wood-burning systems in areas prone to dry conditions and vegetation. A spark arrestor cap prevents embers from escaping the flue, reducing the risk of starting a fire. Regular inspection of the cap is essential to ensure it remains in good condition and continues to perform its intended functions.

In summary, caps are indispensable components of Houston venting systems, providing essential protection against water damage, animal intrusion, and debris accumulation. Proper material selection, installation, and maintenance of caps contribute to the overall safety, efficiency, and longevity of these systems. Challenges include selecting the right cap for specific system types and environmental conditions, as well as ensuring proper installation to prevent leaks and obstructions. This understanding contributes to the broader theme of maintaining safe and efficient heating systems throughout the Houston metropolitan area.

6. Weatherproofing

In the Houston, TX, metropolitan area, the concept of weatherproofing venting systems is paramount due to the region’s unique climatic challenges. These structures are constantly exposed to high humidity, intense rainfall, and the potential for hurricane-force winds, necessitating robust weatherproofing measures.

- Flashing Integrity

Flashing, typically made of metal, is installed at the intersection of the system and the roof to prevent water penetration. In Houston, deteriorated or improperly installed flashing can lead to significant water damage within the system and the adjacent structure. Regular inspections and timely repairs are crucial for maintaining its effectiveness. An example includes replacing corroded flashing around the system’s base to prevent leaks during heavy rainstorms.

- Cap Protection

As mentioned previously, weatherproofing often involves installing a cap designed to prevent rainwater from entering the flue. Houston’s high annual rainfall necessitates caps constructed of durable, weather-resistant materials like stainless steel or copper. Furthermore, the cap design should allow for adequate ventilation while effectively blocking water ingress. Clogged or damaged caps can lead to water saturation of the system’s lining, accelerating deterioration.

- Water Repellent Sealants

Applying water-repellent sealants to the exterior masonry can provide an additional layer of protection against moisture absorption. These sealants penetrate the surface, creating a barrier that prevents water from penetrating the brick or stone. In Houston’s humid environment, this can significantly reduce the risk of freeze-thaw damage and spalling. The selection of appropriate sealants is crucial, as some products can trap moisture and exacerbate deterioration.

- Crown Maintenance

The crown, the concrete or masonry top surface of the system, is particularly vulnerable to water damage. Cracks and deterioration in the crown allow water to penetrate the system’s interior. Weatherproofing often involves repairing or replacing the crown to ensure a solid, waterproof barrier. For instance, applying a waterproof coating to a properly repaired crown will prolong its lifespan and prevent water intrusion.

These weatherproofing facets are essential for preserving the integrity and functionality of venting systems in Houston. Neglecting these measures can lead to costly repairs, safety hazards, and reduced system lifespan. Understanding and implementing effective weatherproofing techniques are critical for maintaining these structures in optimal condition throughout the year.

7. Codes

In the Houston, TX area, adherence to building codes is paramount for the safe and efficient operation of venting systems. These codes, established by municipal and national organizations, govern the design, construction, installation, maintenance, and inspection of these systems. Non-compliance can result in fines, mandated corrective actions, and potential safety hazards, including fire and carbon monoxide poisoning. Local codes, such as those adopted by the City of Houston or Harris County, often reference national standards like the International Residential Code (IRC) and the National Fuel Gas Code (NFGC), tailoring them to regional environmental factors and construction practices.

Practical application involves verifying compliance during every stage from initial construction to routine maintenance. For example, when installing a new wood-burning fireplace, codes dictate required clearances from combustible materials, the proper type of flue liner, and the height of the structure above the roofline. Similarly, gas-burning appliance installations must adhere to specific venting requirements to prevent gas leaks and ensure complete combustion. Regular inspections, performed by certified professionals, assess code compliance, identifying deficiencies such as cracked liners, inadequate clearances, or improper connections. Corrective actions, which may include repairs, replacements, or modifications, must be undertaken to bring the system into compliance.

Understanding these codes is crucial for homeowners, contractors, and inspectors alike. Local jurisdictions may amend national codes to address specific concerns such as high wind conditions or unique architectural styles. Furthermore, code requirements evolve over time, necessitating ongoing education and training to remain current. Maintaining code compliance ensures safety, protects property value, and facilitates smooth real estate transactions. The challenge lies in navigating complex and sometimes overlapping regulations, underscoring the importance of engaging qualified professionals knowledgeable in local building codes related to venting systems in the Houston metropolitan area.

Frequently Asked Questions Regarding Venting Systems in Houston, TX

The following questions address common concerns and misconceptions regarding the maintenance, inspection, and regulatory compliance of venting systems in the Houston metropolitan area.

Question 1: How often should a venting system be inspected?

It is generally recommended that venting systems undergo professional inspection at least annually. Systems connected to wood-burning appliances may require more frequent inspections due to creosote accumulation.

Question 2: What are the signs of a damaged or deteriorating venting system?

Indications of damage include visible cracks in the masonry, spalling brickwork, water stains around the system, and a noticeable odor of combustion byproducts within the residence.

Question 3: Is it necessary to clean a venting system even if it is used infrequently?

Yes. Even infrequent use can lead to the accumulation of debris and creosote, posing a fire hazard. Regular cleaning is essential, regardless of usage frequency.

Question 4: What are the risks associated with neglecting venting system maintenance?

Neglecting maintenance can result in structural damage to the system, increased risk of chimney fires, carbon monoxide poisoning, and non-compliance with local building codes.

Question 5: Are there specific building codes that govern the construction and maintenance of venting systems in Houston?

Yes. The City of Houston and Harris County adopt and enforce building codes based on national standards, such as the International Residential Code (IRC) and the National Fuel Gas Code (NFGC). Local amendments may apply.

Question 6: Can homeowners perform their own venting system repairs?

It is generally not recommended that homeowners attempt repairs on venting systems. Professional expertise is required to ensure safety, code compliance, and the proper functioning of the system. Improper repairs can exacerbate existing problems and create new hazards.

Proper maintenance, regular inspections, and adherence to building codes are critical for the safe and efficient operation of venting systems. Addressing potential issues promptly can prevent costly repairs and protect against potential hazards.

The subsequent section will explore available resources for homeowners seeking professional venting system services in Houston.

In Closing

The preceding exploration of aspects relevant to structures designed to vent combustion gases and smoke in the Houston, Texas, metropolitan area underscores the importance of proactive management. From understanding local codes and environmental challenges to implementing regular inspections and maintenance protocols, property owners must prioritize the safety and efficiency of these systems. Key points include the need for qualified professionals, appropriate materials, and adherence to evolving regulatory standards.

Continued vigilance and investment in proper upkeep will ensure structural integrity, reduce the risk of hazards, and contribute to the overall well-being of the community. Ignoring these considerations can lead to significant consequences, emphasizing the necessity for responsible action. As Houston continues to grow and evolve, the emphasis on safe and compliant venting systems must remain a constant priority.

![Why Chimney Birds Matter: [Chimney Bird] Care Tips Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Why Chimney Birds Matter: [Chimney Bird] Care Tips | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/03/th-25-300x200.jpg)